Tooling and forming process for forming aircraft skin parts of hook type

A technology of aircraft skin and forming process, applied in the field of sheet metal forming and manufacturing, can solve the problems of poor structural integrity, reduce production efficiency, reduce competitiveness, etc., to increase overall strength and rigidity, reduce production costs, and reduce the number of divisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

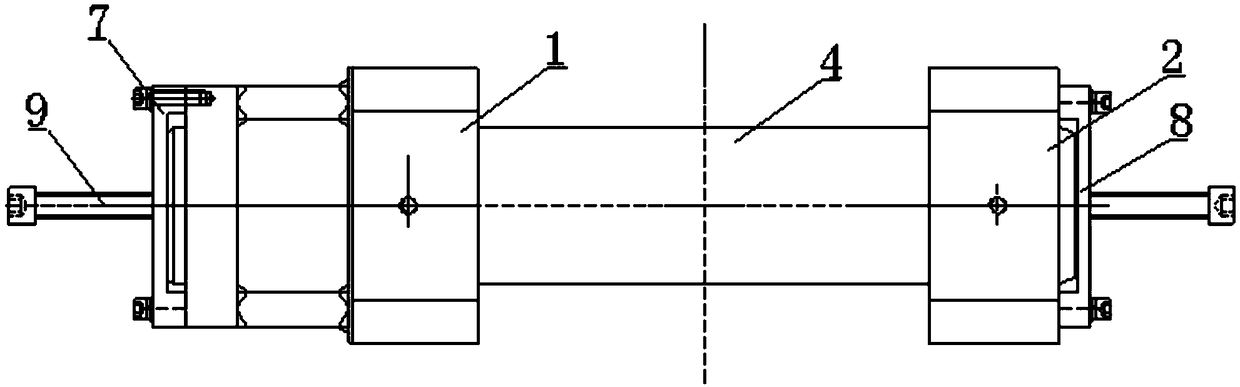

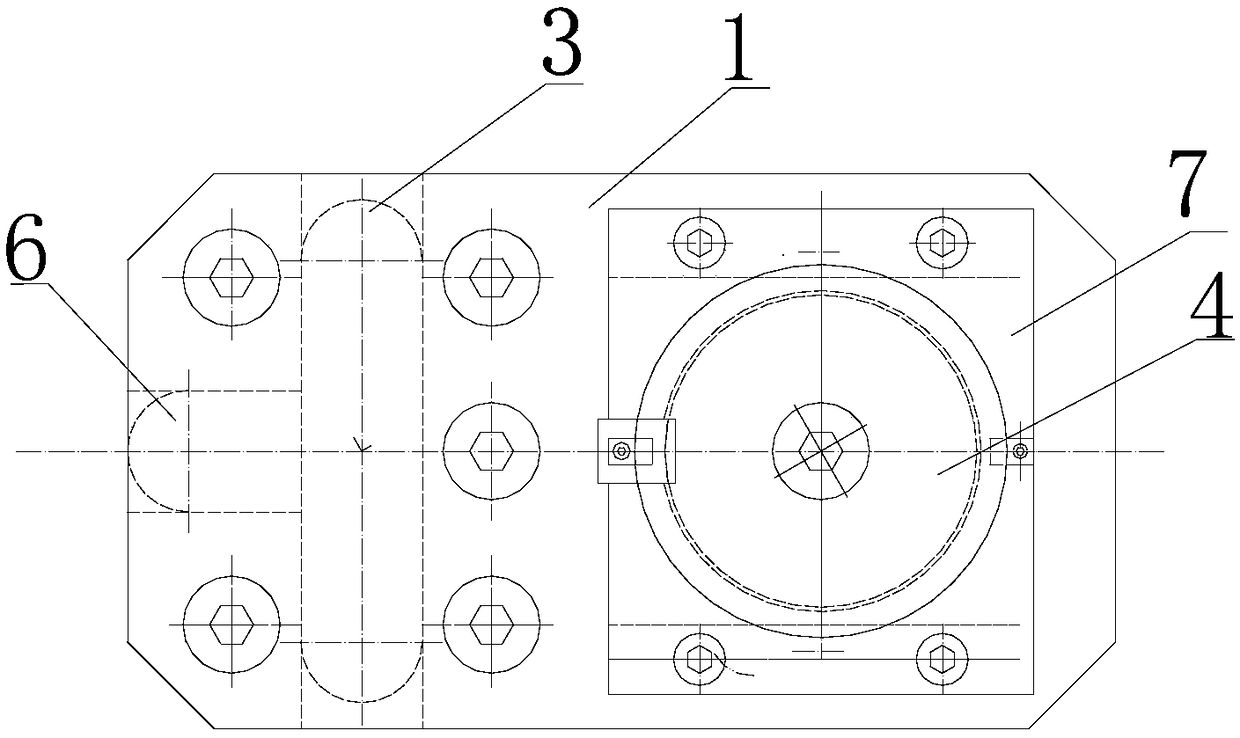

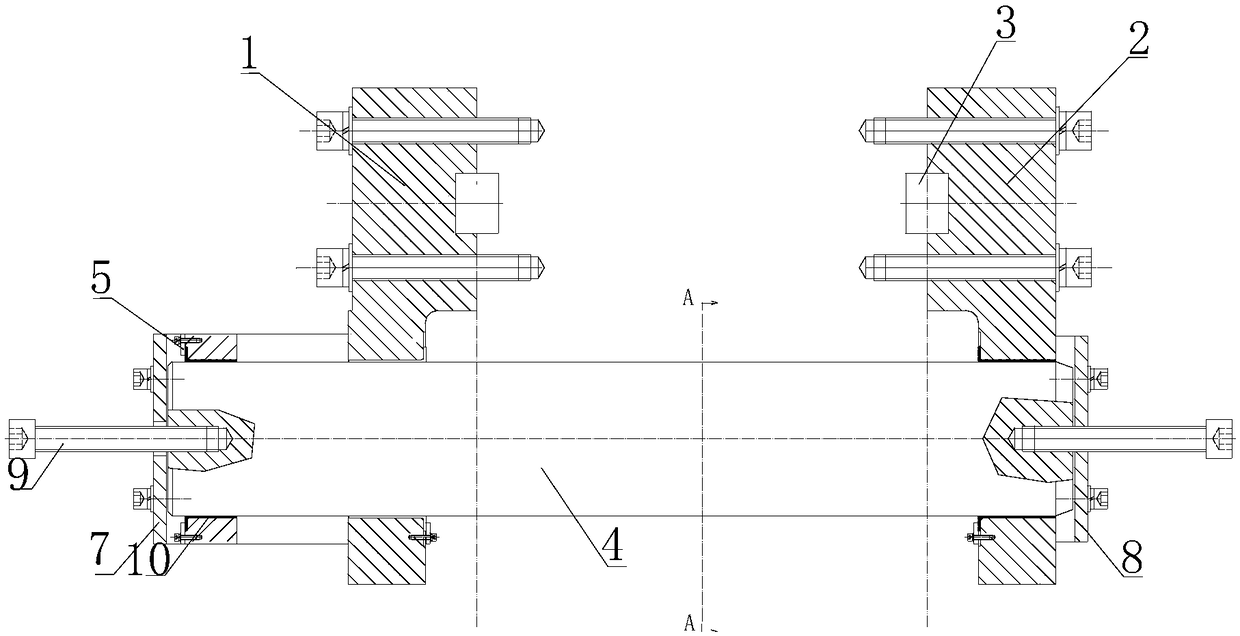

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0031] see Figure 1-Figure 4 , tooling for forming hook-type aircraft skin parts, including symmetrically arranged left bracket 1 and right bracket 2, said left bracket and right bracket are provided with concentric shaft holes, which are dynamically fitted on the left bracket and right bracket shaft holes Roller 4 is housed, and described roller one end is fixed with left support by left end cover 7, and the other end of roller is fixed with right support by right end cover 8, and the inner side corresponding to described left support and right support is provided with for installing respectively. The horizontal key 3 and the vertical key 6 of the mold.

[0032] In this embodiment, composite guide sleeves 10 are embedded in the parts where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com