Iron wire continuous cutting and bending all-in-one machine for bundling

An all-in-one machine and iron wire technology, which is applied in the field of iron wire cutting, can solve the problems of reducing the production speed of iron wire loops, increasing the production cost, and greatly manpower, etc., and achieves the effects of simple structure, improved work efficiency, and large frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

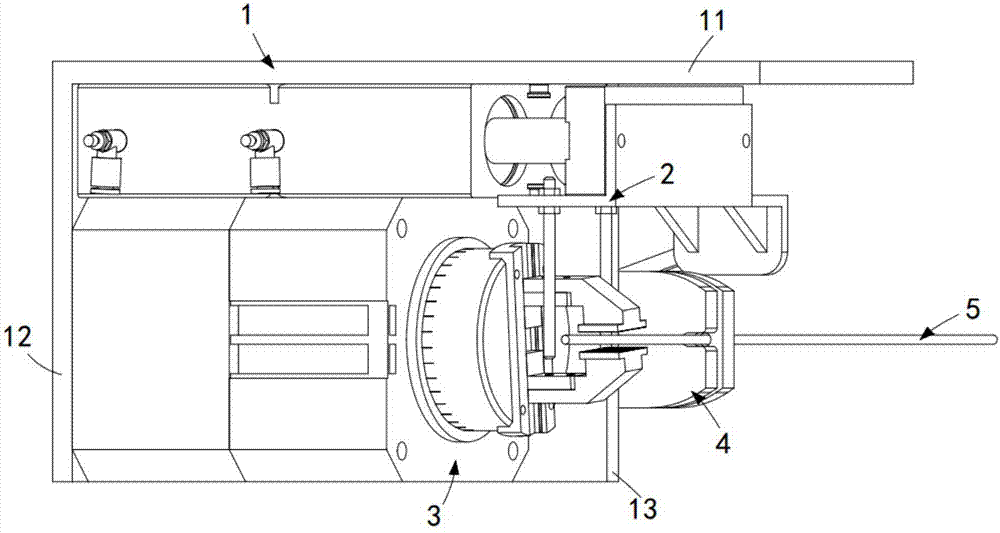

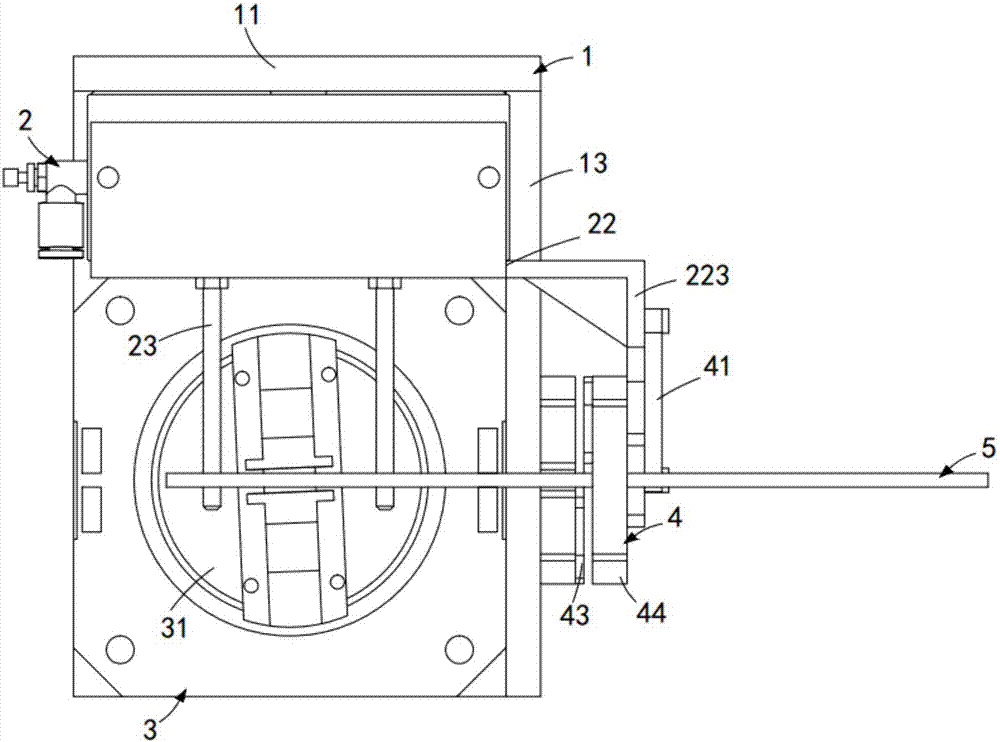

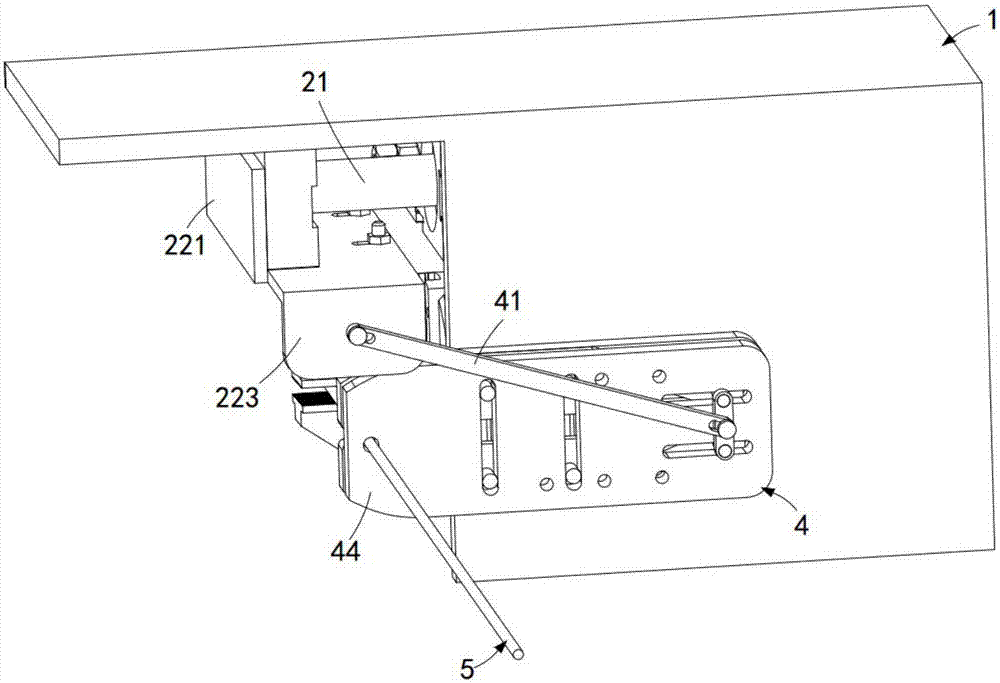

[0046] Such as figure 1 As shown, a continuous shearing and bending integrated machine for binding iron wire includes a mounting plate 1, the mounting plate 1 includes a first mounting portion 11, and a second mounting portion 12 vertically arranged to the first mounting portion 11, respectively. With the third installation part 13, the first installation part 11 is located at the top of the installation board 1, the second installation part 12 is located at the rear side of the first installation part 11, and the third installation part 13 is located at the top of the installation board 1. The right side of the first installation part 11 also includes:

[0047] Bending assembly 2, described bending assembly 2 is installed on the described first mounting part 11, and it carries out bending work to iron wire 5;

[0048] Clamping assembly 3, described clamping assembly 3 is installed on the described second mounting part 12, and it is positioned at the directly below described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com