Fireproof artificial quartz sheet material

A quartz and artificial technology, which is applied in the field of fire-resistant artificial quartz plates, can solve the problems of artificial quartz stones that cannot be bent and low fire resistance, and achieve the effects of increasing aesthetics, improving flame retardant effect, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following specific examples will be used to describe the present invention in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

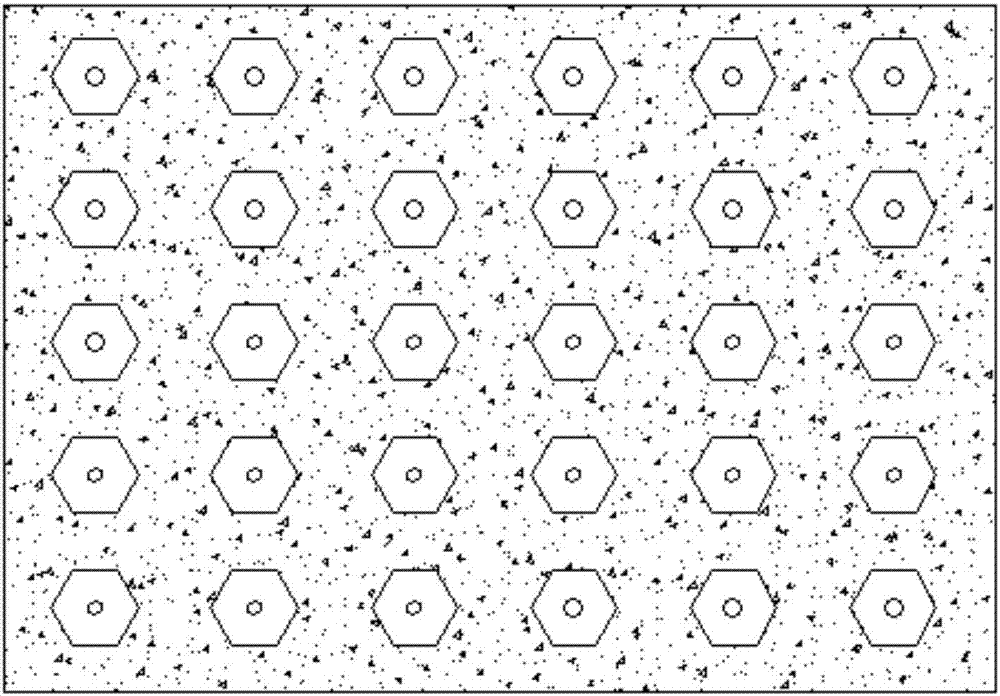

[0029] Such as Figure 1 to Figure 3 As shown, a fire-resistant artificial quartz plate, fire-resistant artificial quartz plate components: more than 85% of natural quartz sand, 2% of fumed silica, 8% of resin and curing agent, 5% of mica flakes and 2% of Antimony trioxide, and more than 3% frog stone.

[0030] As an improvement to the above-mentioned embodiment, the manufacturing process of the fireproof artificial quartz plate:

[0031] 1) First, the natural quartz sand is screened to remove impurities, and fumed silica and antimony trioxide are fully mixed with resin and curing agent to form a fireproof adhesive;

[0032] 2) One part of natural quartz sand after screening and removal of impurities is fully mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com