Method for increasing fermentation yield of gentamicin B

A gentamicin and yield technology is applied in the field of increasing the fermentation yield of gentamicin B, which can solve the problems of long fermentation period, many components, and low content, and achieve the advantages of reducing production cost, shortening fermentation period and increasing yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

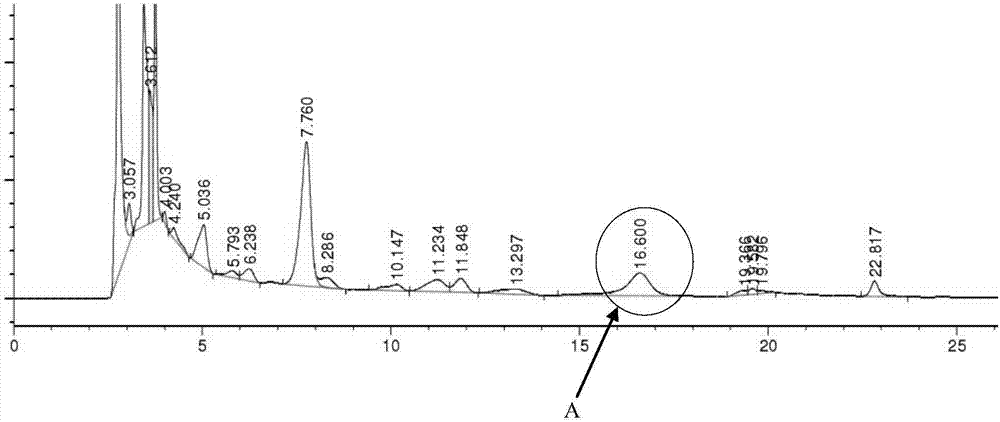

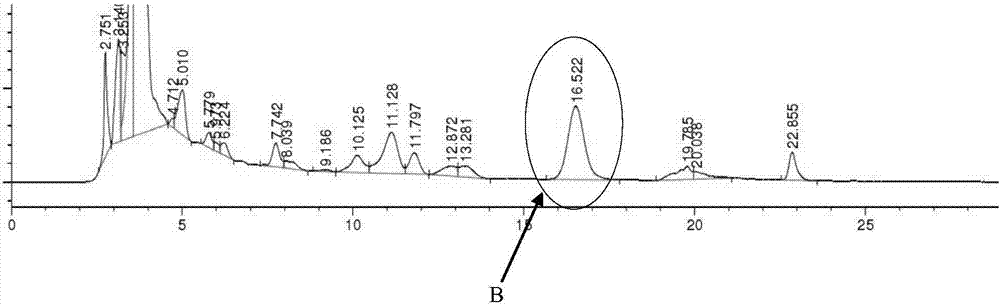

Image

Examples

Embodiment 1

[0025] This embodiment discloses a first embodiment of a method for improving the fermentation yield of gentamicin B, and specifically includes the following steps:

[0026] Step (1): Inoculate the gentamicin B-producing bacteria on the slant medium and culture at 35° C. for 5 days.

[0027] Step (2): Select mature gentamicin B-producing bacteria and inoculate them on the shake flask medium, cultivate them on a shaker, cultivate them at 35°C and 210rmp for 45h, and inoculate them in the first-level seed medium of the first-level seed tank cultured at 33°C for 45h, then transplanted to the secondary seed medium of the secondary seed tank, and cultivated at 33°C for 20h. Wherein, the inoculum amount of the shake flask culture medium is 10%.

[0028] Step (3): Inoculate on the fermentation medium of the fermenter, and the fermentation is carried out at 33°C, the tank pressure is 0.04Mpa, and the ventilation rate is 1:1.2vvm. Add inorganic salt solution to 20 hours after ferment...

Embodiment 2

[0038] This embodiment discloses a second specific implementation of the method for improving the fermentation yield of gentamicin B, and specifically includes the following steps:

[0039] Step (1): Inoculate the gentamicin B-producing bacteria on the slant medium, and culture at 37° C. for 6 days.

[0040] Step (2): Select the mature gentamicin B-producing bacteria and inoculate it on the shake flask culture medium, cultivate it on a shaker, cultivate it at 37°C and 220rmp for 50h, and inoculate it in the first-level seed medium of the first-level seed tank cultured at 35°C for 50h, transplanted to the secondary seed medium of the secondary seed tank, and cultivated at 35°C for 24h. The inoculum size of the shake flask medium was 12%.

[0041] Step (3): Inoculate on the fermentation medium of the fermenter, and ferment at 35°C. The tank pressure is 0.05Mpa, and the ventilation volume is 1:1.5vvm. Fermentation is carried out to 25h to add inorganic salt solution, fermentat...

Embodiment 3

[0049] This embodiment discloses a third embodiment of the method for improving the fermentation yield of gentamicin B, and specifically includes the following steps:

[0050] Step (1): inoculate the gentamicin B-producing bacteria on the slant medium, and culture at 38° C. for 7 days.

[0051] Step (2): Select the mature gentamicin B-producing bacteria slant and inoculate it on the shake flask medium, cultivate it on a shaker, cultivate it at 38°C and 230rmp for 55h, and inoculate it in the first-level seed medium of the first-level seed tank cultured at 37°C for 55 hours, transplanted to the secondary seed medium of the secondary seed tank, and cultivated at 37°C for 28 hours. The inoculum size of the shake flask medium was 15%.

[0052] Step (3): Inoculate on the fermentation medium of the fermenter, and the fermentation is carried out at 37°C, the tank pressure is 0.03Mpa, and the ventilation rate is 1:0.5vvm. Fermentation proceeds to 30h to add inorganic salt solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com