Method for improving permeability through coal mine downhole slotting pressure-maintaining guide fracturing

A slotting and guiding technology, applied in mining equipment, earthmoving, wellbore/well components, etc., can solve problems such as poor control ability, high construction cost, and low extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

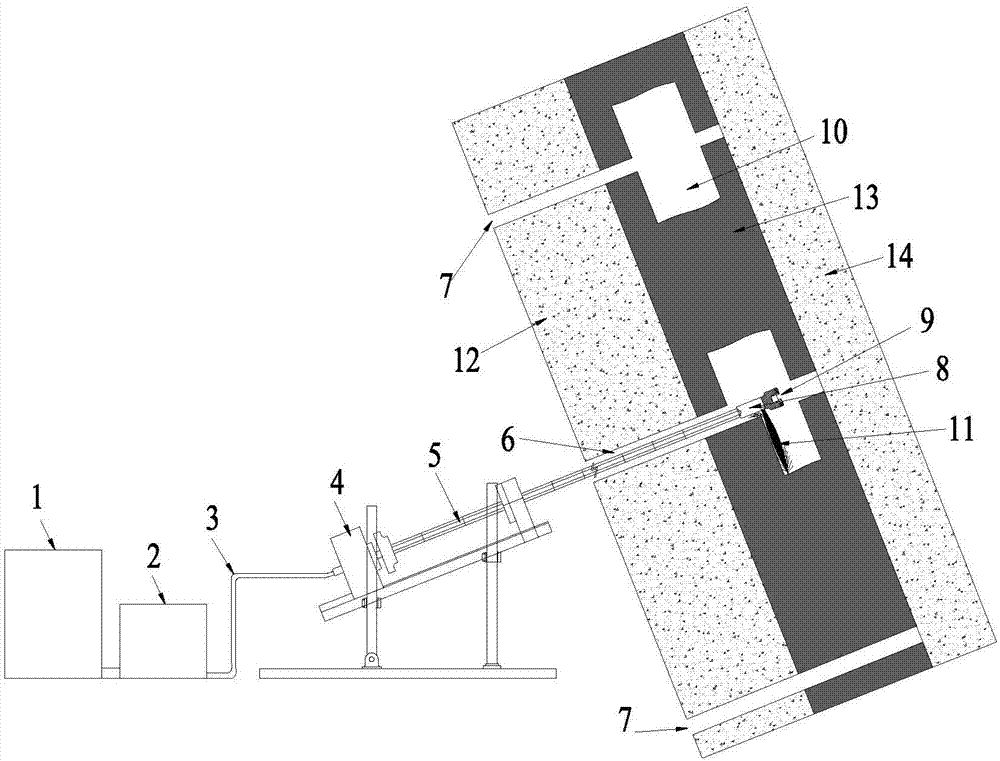

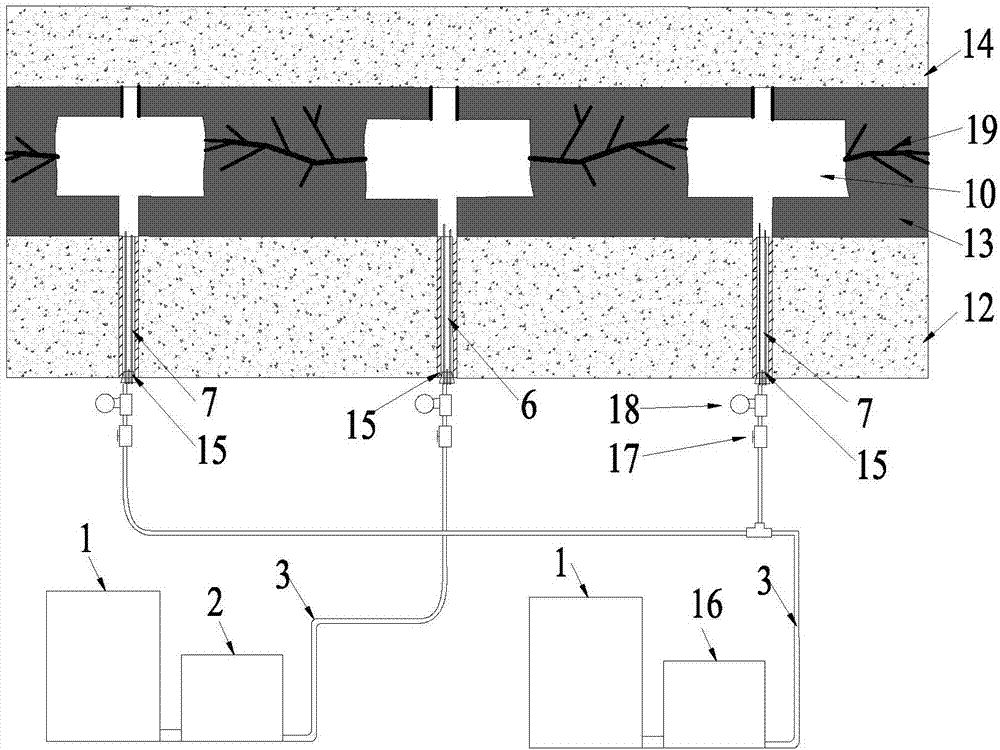

[0036] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

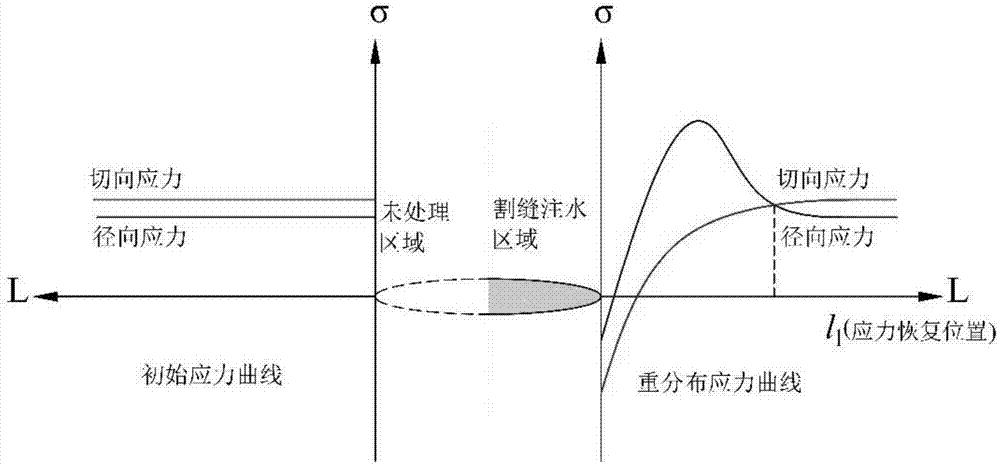

[0037] Assumed coal seam stress σ 1 10MPa, σ 3 is 8MPa, the elastic modulus of coal is 15GPa, and the tensile strength is σ t When it is 0.5MPa, the fracture initiation pressure is about 9MPa calculated according to the existing theory.

[0038] a. Calculate the slot design parameters by the following formula:

[0039]

[0040] In the above formula, σ ρ Minimum principal stress before stress redistribution, σ θ Maximum principal stress before stress redistribution, A 1 、A 2 、A 3 , B 1 , B 2 , B 3 is the coefficient, σ 1 , σ 3 is the far field stress, p w is the water injection pressure;

[0041] and coefficient A 1 、A 2 、A 3 , B 1 , B 2 , B 3 satisfy the following equation:

[0042]

[0043] In the above formula, α is the slot azimuth, ρ is the mapping guide distance, m=(a-b) / (a+b), a and b are the major axis and minor axis of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com