Clutch having transport fixed device, and method for producing clutch

A clutch and transmission technology, applied in the field of clutches, to achieve the effect of improving economic efficiency, time efficiency and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

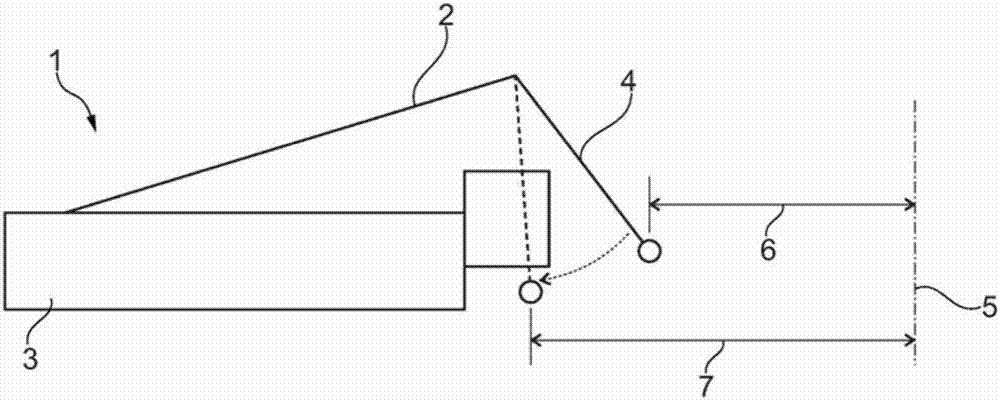

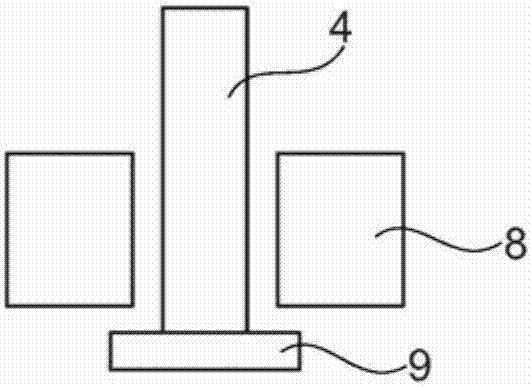

[0036] figure 1 A schematic diagram of clutch 1 is shown. In an operating state, the pressure pot 2 can be coupled to the pressure plate 3 so that a torque can be transmitted via the clutch 1 . Furthermore, a clamping plate 4 is provided on the pressure pot 2 in order to achieve an axial fixation, preferably during transport of the clutch 1 . figure 1 The arrangement of is arranged rotationally symmetrically around the axis of rotation 5 . The axial direction is arranged on the axis of rotation 5 .

[0037] The clamping plate 4 is designed such that it is not axially coupled / connected to the compression plate 3 in the first operating state. This first operating state is shown by means of a solid line. In the second operating state, the clamping plate 4 assumes such a position that the pressure vessel 2 and the pressure plate 3 are at least partially coupled axially figure 1 Indicated by dashed lines.

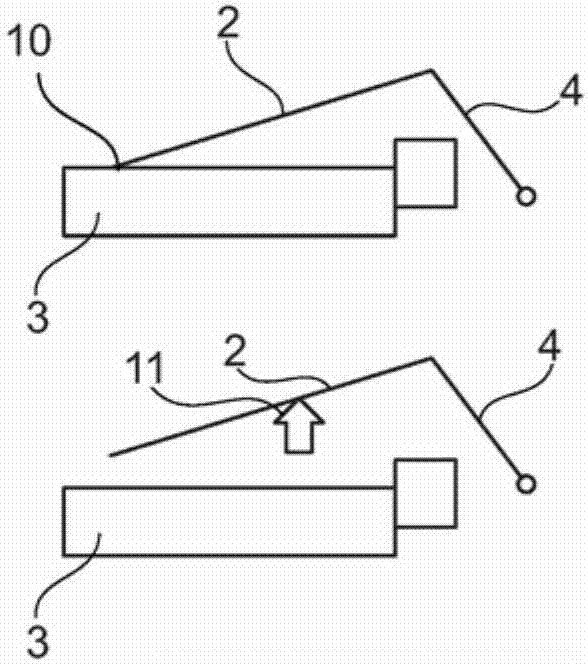

[0038] The plastic deformation according to the invention of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com