A vacuum design method for sealed cesium beam tube

A design method and technology for a cesium beam tube are applied in the field of vacuum design of a sealed cesium beam tube, which can solve the problems of unsatisfactory vacuum degree, lack of a vacuum design method for a sealed cesium beam tube, and high cost, so as to reduce the design cost and improve the development success. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

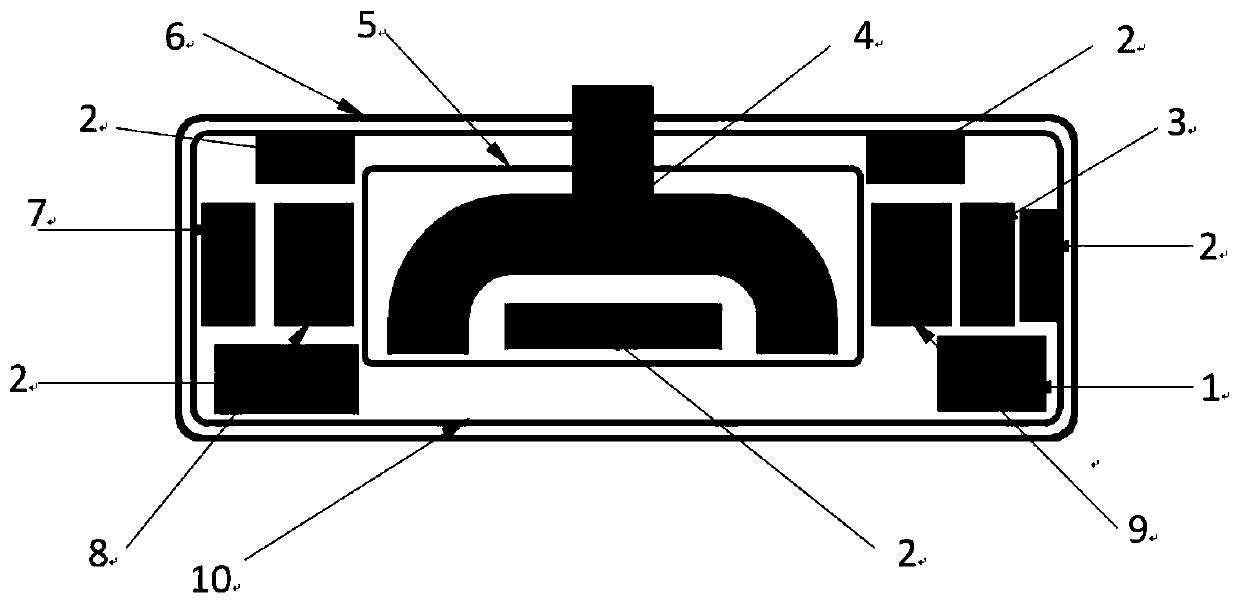

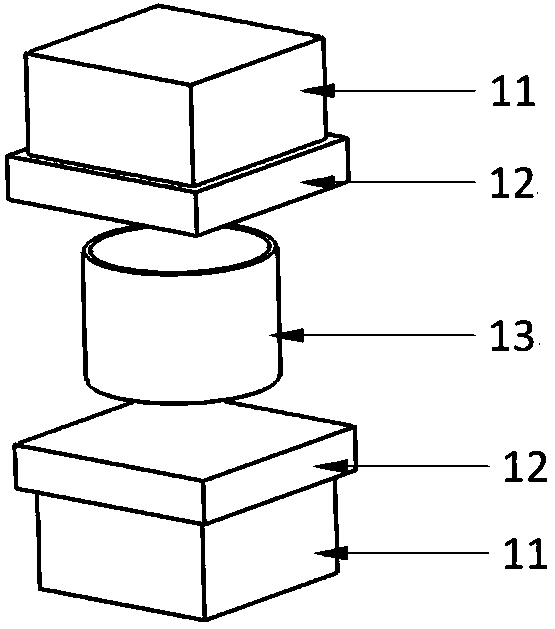

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0020] The invention provides a vacuum design method for a magnetically separated sealed cesium beam tube, comprising the following steps:

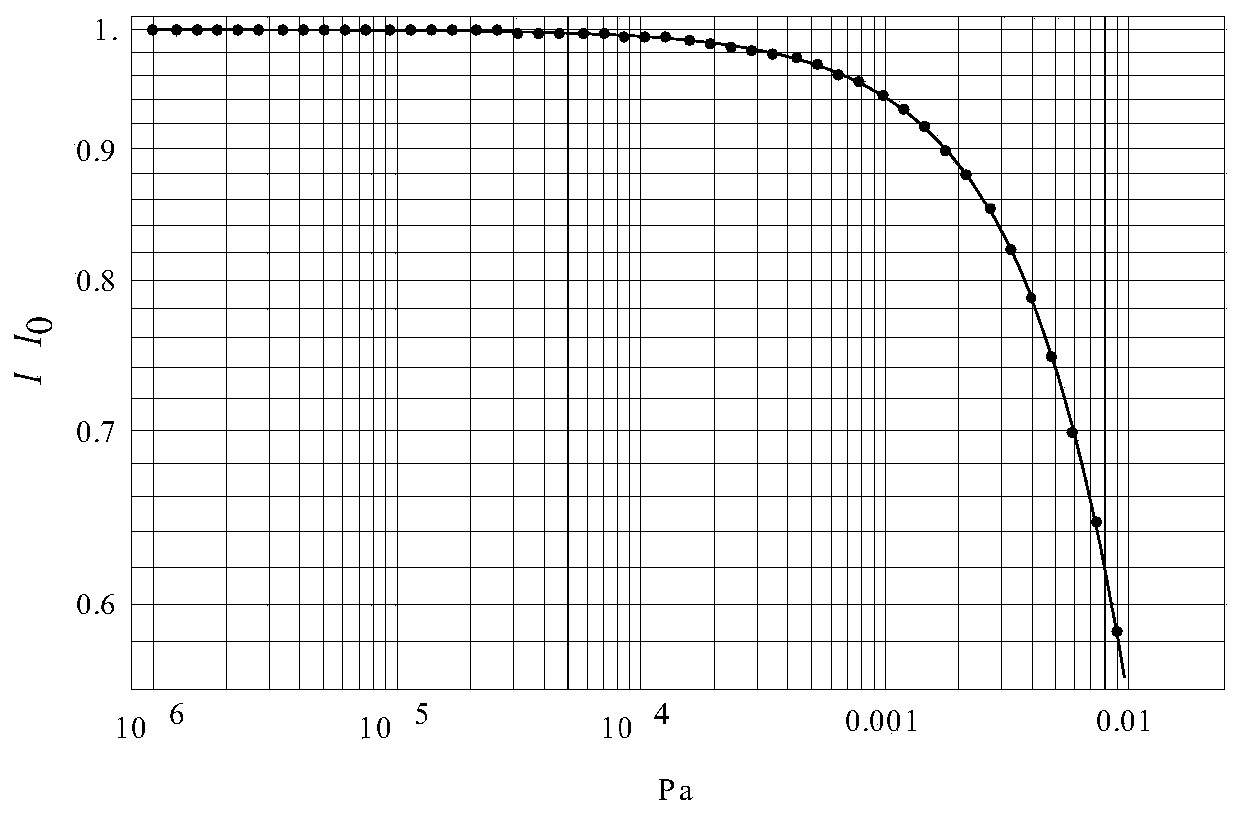

[0021] Step 1, according to the relationship between the intensity of the cesium atom beam and the pressure inside the cesium beam tube, the working pressure range of the cesium beam tube is obtained.

[0022] The change of the atomic beam intensity (that is, the beam intensity, the number of atoms per unit area per unit time) comes from two aspects. One is that the beam intensity continues to decrease due to the continuous expansion of the cross-section of the beam in the forward direction, and the other is that Due to the existence of residual gas molecules in the cesium beam tube, the beam intensity decreases with the distance from the cesium furnace collimator. To complete the vacuum design, it is sufficient to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com