Temperature characteristic analysis method for optical fiber composite submarine cable under overload operation

A submarine cable, temperature characteristics technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of the increase in the growth rate of submarine cables and the lack of intuitive and effective methods for research on the overload of three-core optical fiber composite submarine cables, Affecting the service life of the submarine cable and other issues, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] Such as Figure 7 Shown, the present invention comprises the following steps:

[0043] 1) Finite element modeling of submarine cable:

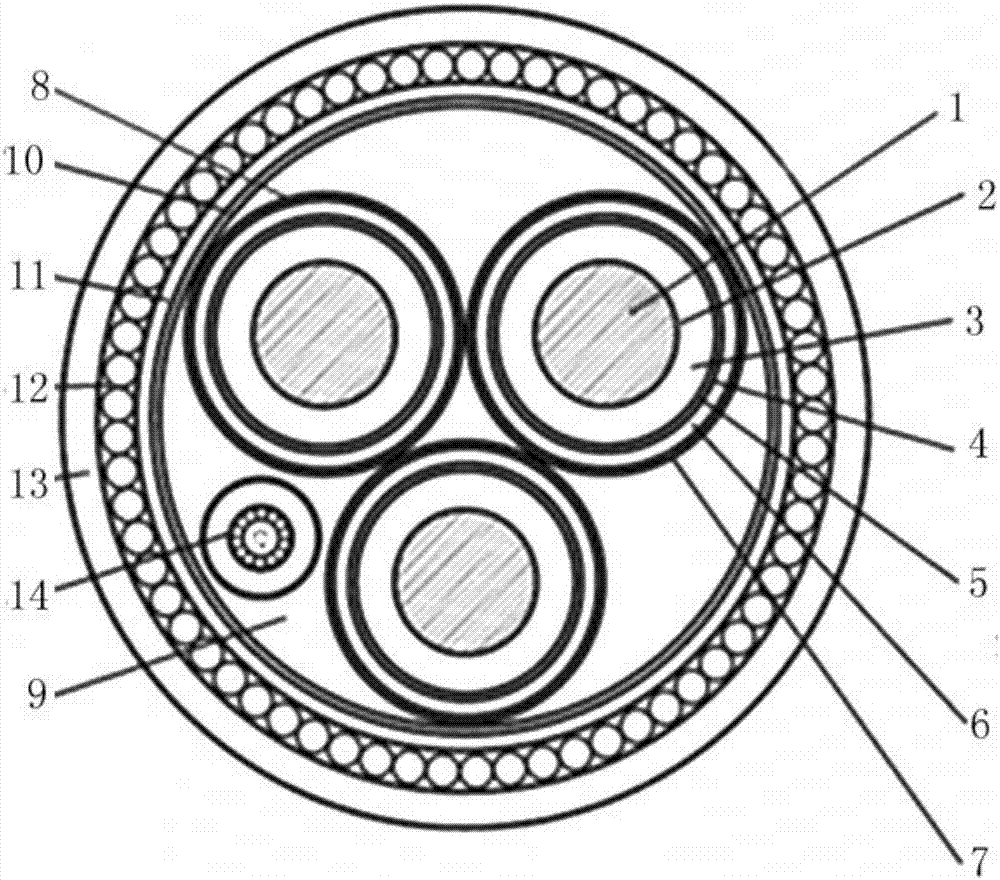

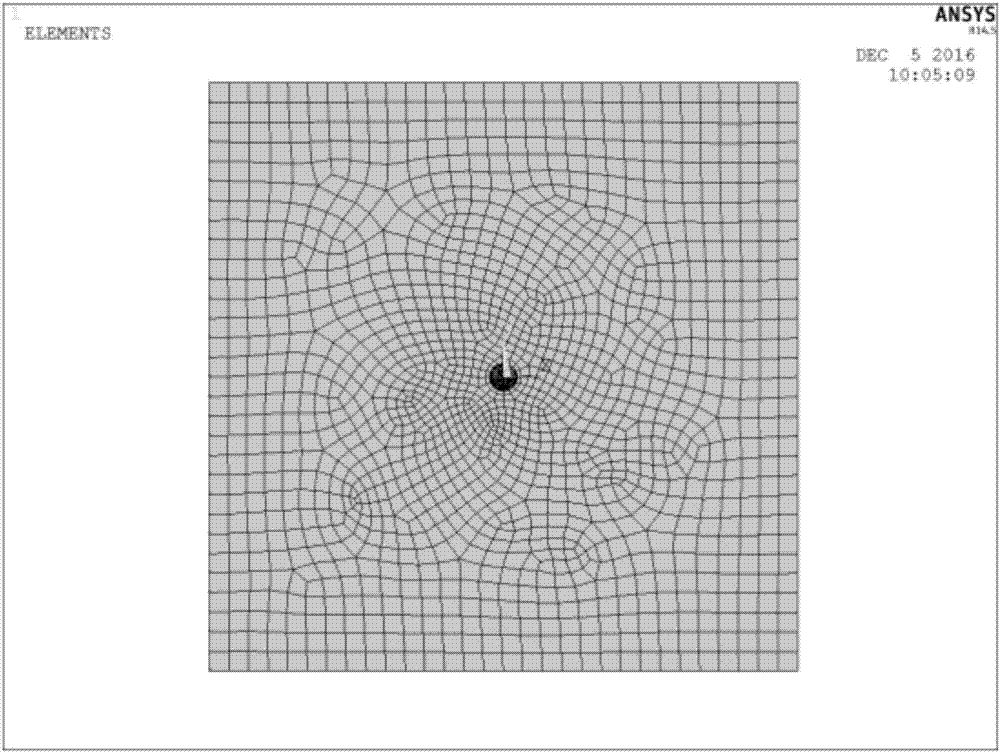

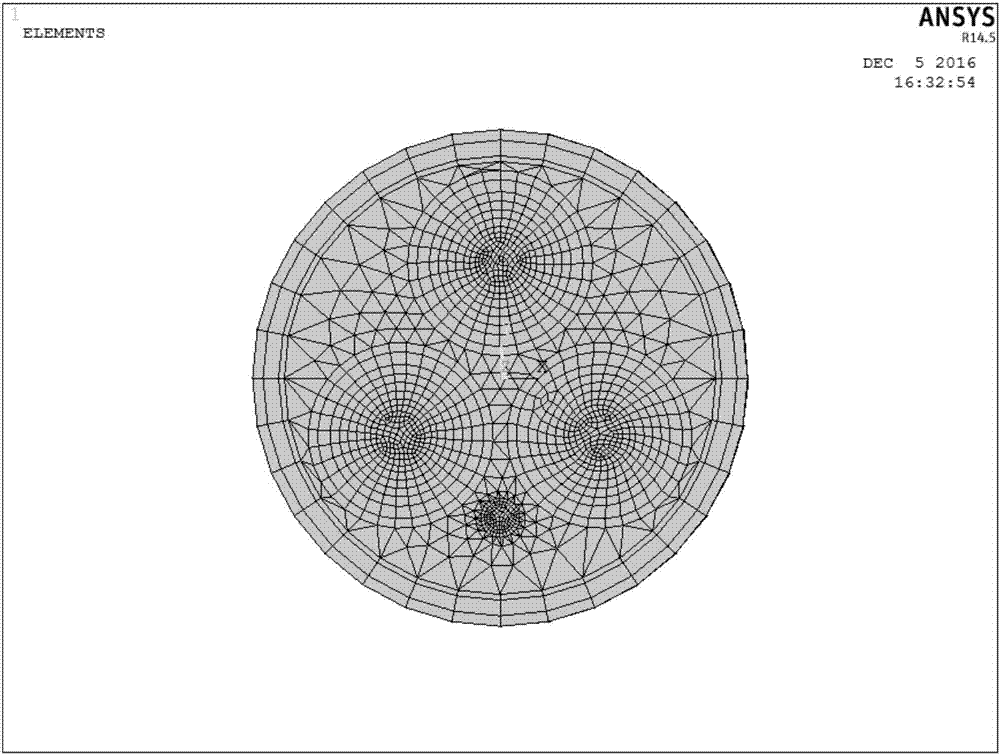

[0044] 1) The geometric model is established. When modeling, the conductor shielding layer, XLPE insulating layer and insulating shielding layer are combined to form an insulating layer, and the anti-corrosion layer and PE sheath are combined to form an inner sheath; when establishing a submarine cable model, use a cylinder Instead of the twisted structure of the submarine cable; the submarine cable is deeply buried in the seabed soil, the soil layer of the seabed around the cable is set to be the same as the length of the cable, the cable is located in the center of the soil layer, and the side length of the soil layer is set to be the length of the cable 2 times the actual laying depth;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com