Cavity sound absorption wedge complex with metal skeletons

A technology of sound-absorbing wedges and metal skeletons, which is applied in the direction of sound-emitting devices and instruments, can solve problems such as limitations and inapplicability, and achieve the effects of increasing damping loss factors, increasing losses, and enhancing sound-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

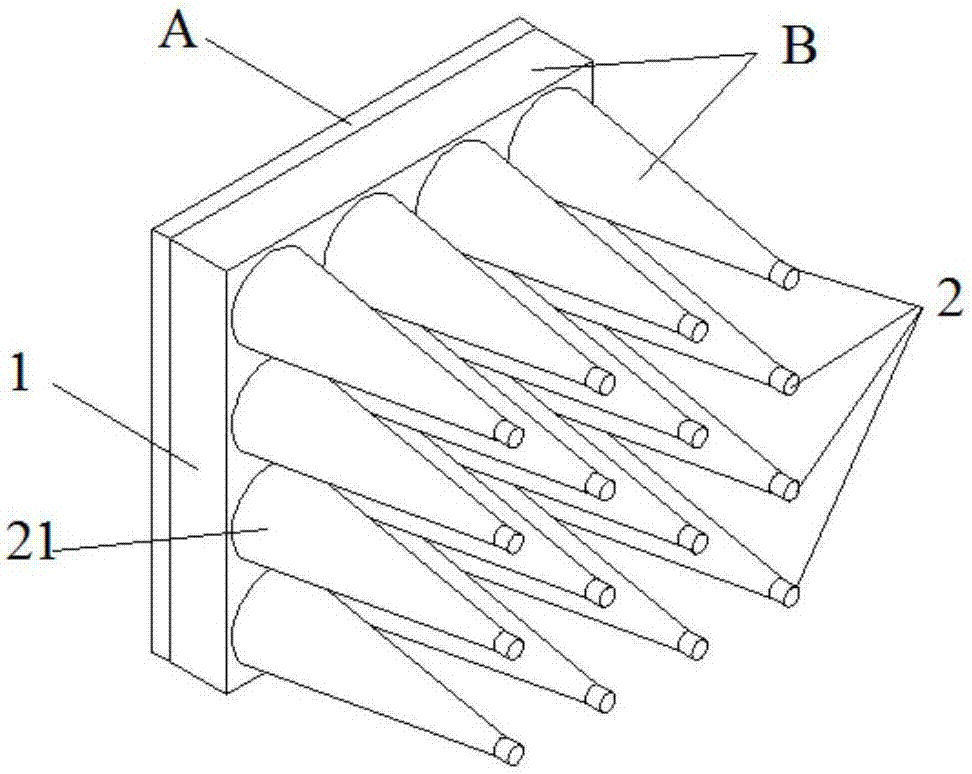

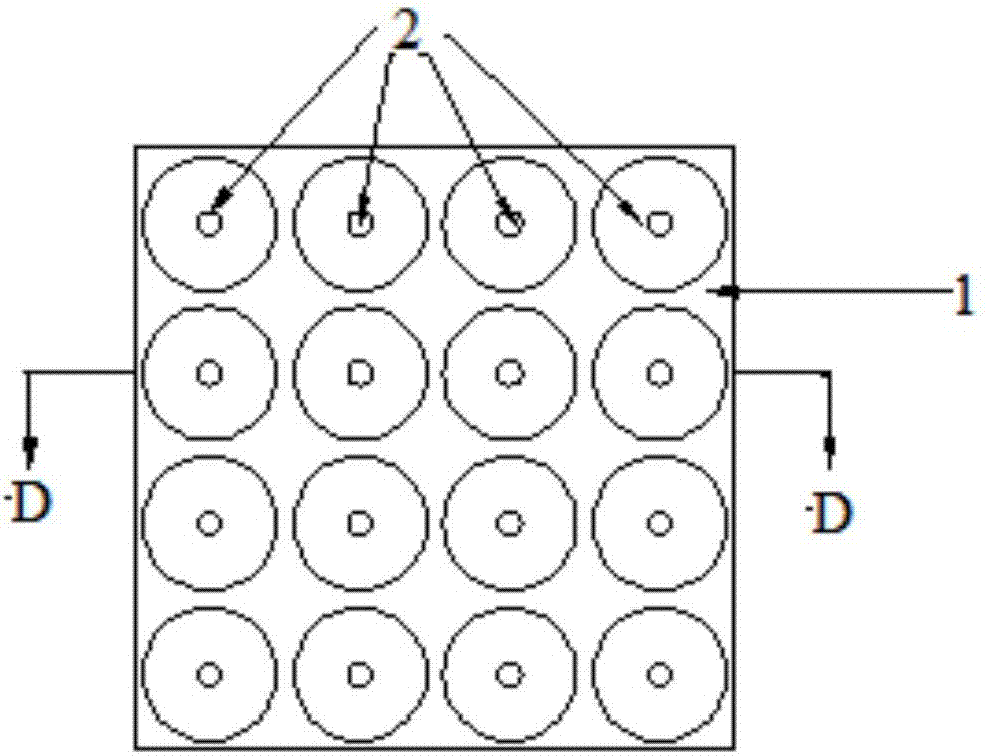

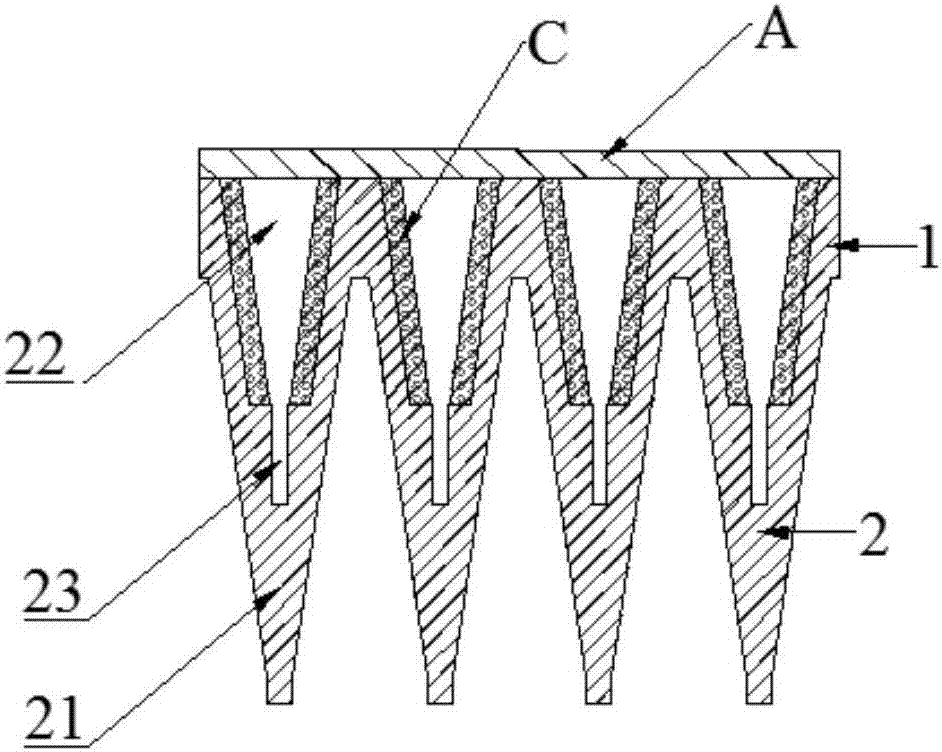

[0031] combine Figure 1-3 Describe this embodiment, a hollow sound-absorbing wedge complex with a metal skeleton in this embodiment, the wedge complex includes a sound-absorbing bottom plate A, a sound-absorbing wedge B and n metal skeletons C; The splitter B is fixedly connected above the sound-absorbing floor A; the sound-absorbing wedge B includes a base 1 and a tip 2; the base 1 and the tip 2 are integrally formed; the base 1 is a cuboid; the tip 2 consists of n conical tips The unit 21 is composed; the tip unit 21 is arranged in an array on the upper surface of the base 1, and the tip is upward; the inside of each tip unit 21 is provided with a conical cavity 22; the bottom of the conical cavity 22 extends to the bottom of the base 1 Bottom, and the top port diameter of truncated conical cavity 22 reduces, and along the central axis of truncated conical cavity 22, the tip of wedge unit 21 extends with elongated cavity 23; The wall of each said tip unit 21 One metal skel...

Embodiment approach 2

[0052] This embodiment is further limited to the base portion 1 and the tip portion 2 in the first embodiment. In this embodiment, the height ratio of the base portion 1 to the tip portion 2 is 1:4˜1:5.

[0053] The height ratio of the base part 1 to the tip part 2 defined in this embodiment is 1:4-1:5, and the effect is best when the height ratio of the base part 1 to the tip part 2 is 1:4. The above parameters are all optimized by simulation to obtain the optimal result of the sound absorption coefficient curve in the working frequency band.

Embodiment approach 3

[0055] This embodiment is to further limit the size ratio of the sound-absorbing wedge B in any of the first to second embodiments. In this embodiment, the sum of the heights of the frustum-shaped cavity 22 and the elongated cavity 23 is equal to The height ratio of B is 3:5; the height ratio of the frustum-shaped cavity 22 and the strip-shaped cavity 23 is 2:1.

[0056] The size ratio of the sound-absorbing wedge B defined in this embodiment, the above-mentioned ratio is the result obtained through simulation optimization to obtain the optimal sound absorption coefficient curve in the working frequency band.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com