Device and method for using laser to induce plasmas to process non-metallic material

A non-metallic material and plasma technology, which is applied in the direction of plasma, lasers, laser parts, etc., can solve the problems of poor quality of non-metallic materials, and achieve the effects of small heat-affected zone, high processing precision and high energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

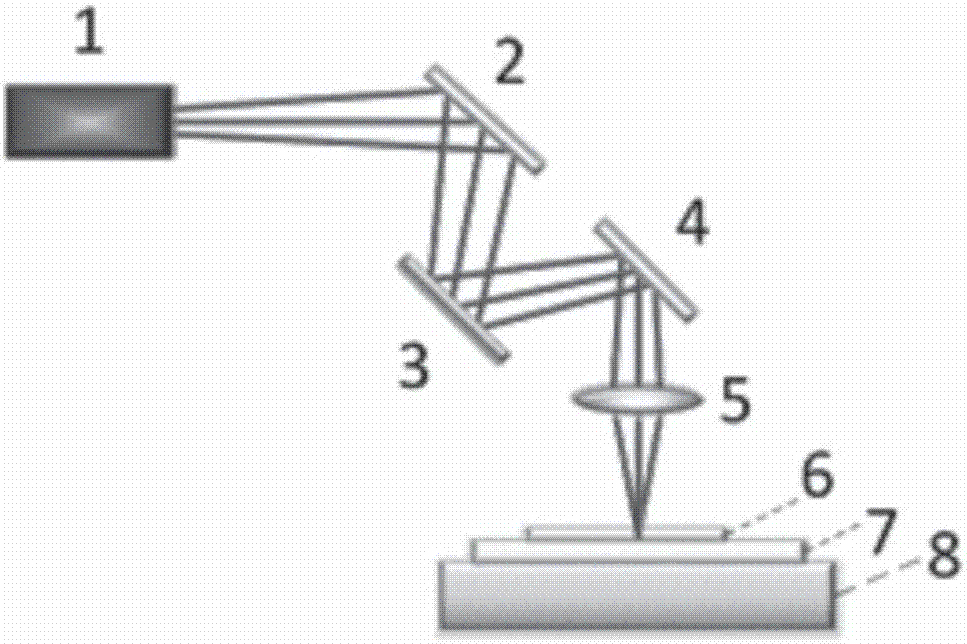

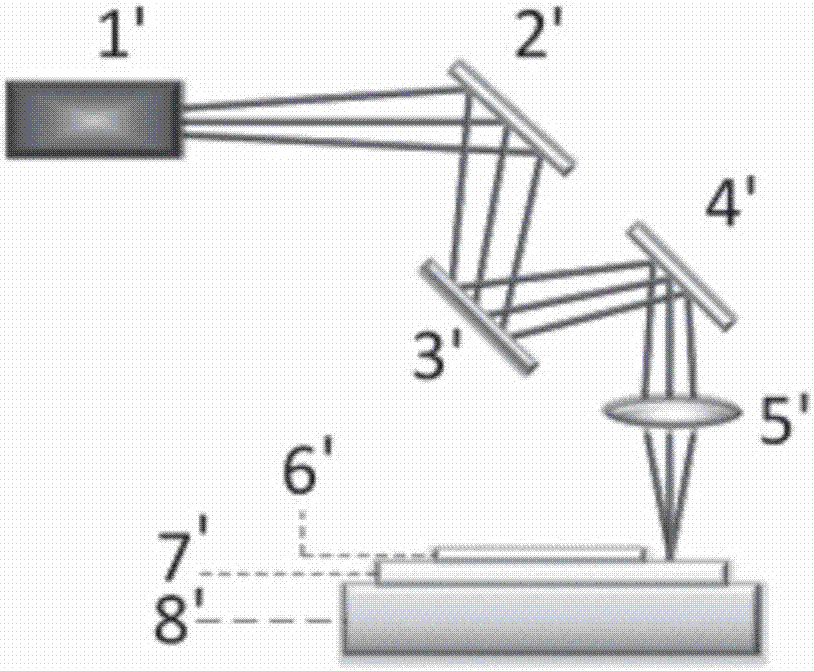

Method used

Image

Examples

Embodiment 1

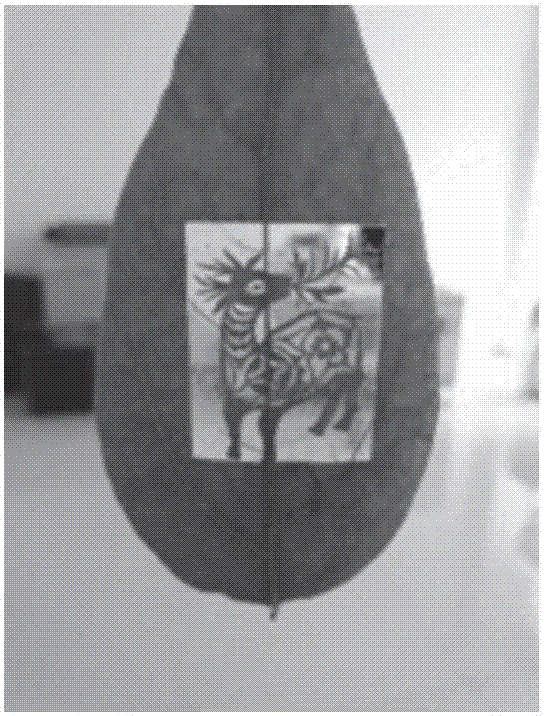

[0038] Use a laser to generate a high peak power laser pulse to act on the surface of the stainless steel plate to generate plasma on the surface of the stainless steel plate; then use the plasma to process the leaves to realize the processing of the leaves; the high peak power of the high peak power laser pulse is 10KW, the peak The width of the maximum power laser pulse is 500ns, the frequency of the high peak power laser pulse is 100Hz, the average power of the high peak power laser pulse is 1W, and the wavelength of the high peak power laser pulse is 200nm. image 3 As shown, the processing ablation marks are few, and the processing quality is high.

Embodiment 2

[0040] Use a laser to generate a high peak power laser pulse to act on the surface of the iron plate to generate plasma on the surface of the iron plate; then use the plasma to process the leaves to realize the processing of the leaves; the high peak power of the high peak power laser pulse is 1GW, the peak The width of the maximum power laser pulse is 1fs, the frequency of the high peak power laser pulse is 100kHZ, the average power of the high peak power laser pulse is 1KW, and the wavelength of the high peak power laser pulse is 2μm. The effect of processing leaves is as follows Figure 4 As shown, the processing ablation marks are few, and the processing quality is high.

Embodiment 3

[0042] Using a laser to generate a high peak power laser pulse acts on the surface of the carbon steel plate to generate plasma on the surface of the carbon steel plate; then use the plasma to process the paper to realize the processing of the paper; the high peak power of the high peak power laser pulse is 100KW, the peak The width of the maximum power laser pulse is 800ns, the frequency of the high peak power laser pulse is 500Hz, the average power of the high peak power laser pulse is 100W, and the wavelength of the high peak power laser pulse is 800nm. Figure 5 As shown, the processing ablation marks are few, and the processing quality is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com