Controller and generator-motor starting method

A technology for generating motors and control devices, which is applied in the direction of controlling generators, motor generators/starters, starters of single multi-phase induction motors, etc., and can solve the problem of inability to increase the speed of variable-speed generator motors, reduce the speed, and increase machine costs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments will be described below with reference to the drawings.

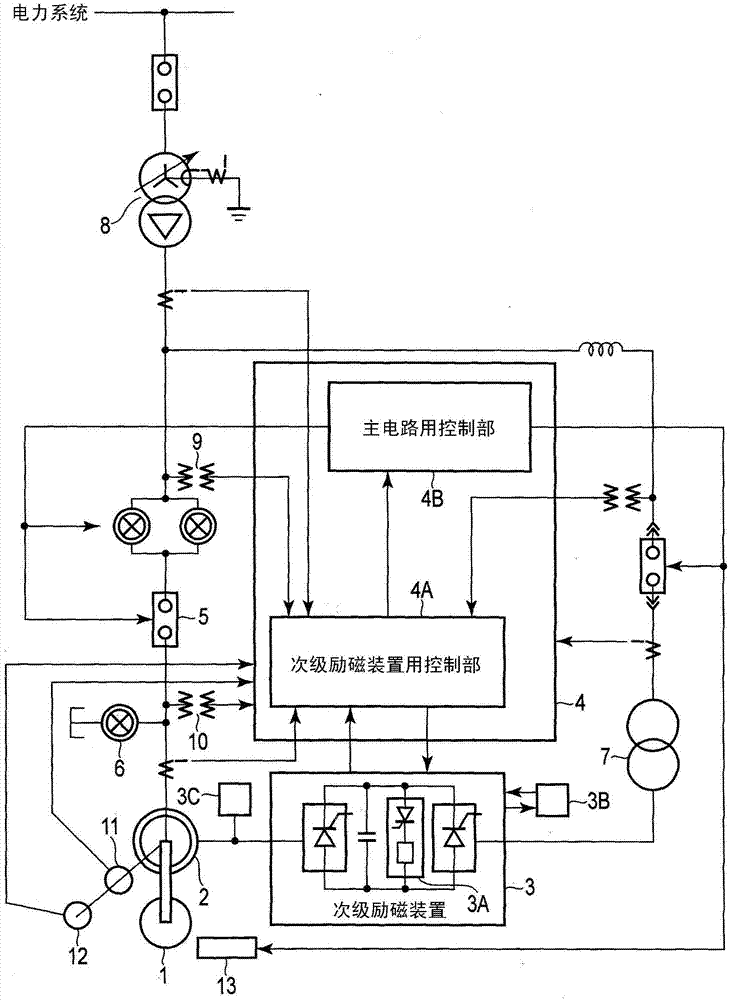

[0017] figure 1 It is a block diagram showing the basic configuration of the variable-speed pumping power generation system according to the embodiment.

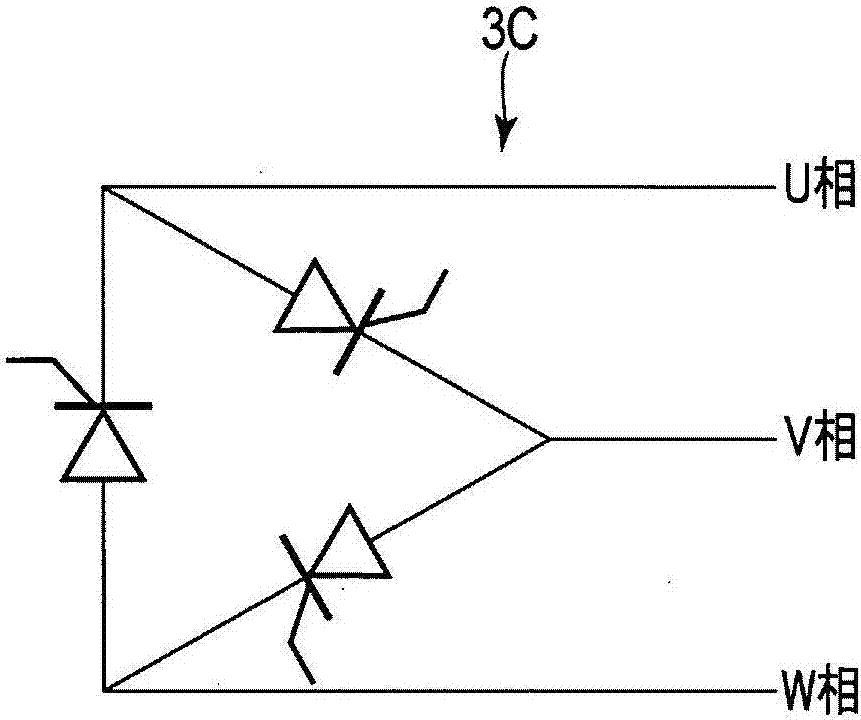

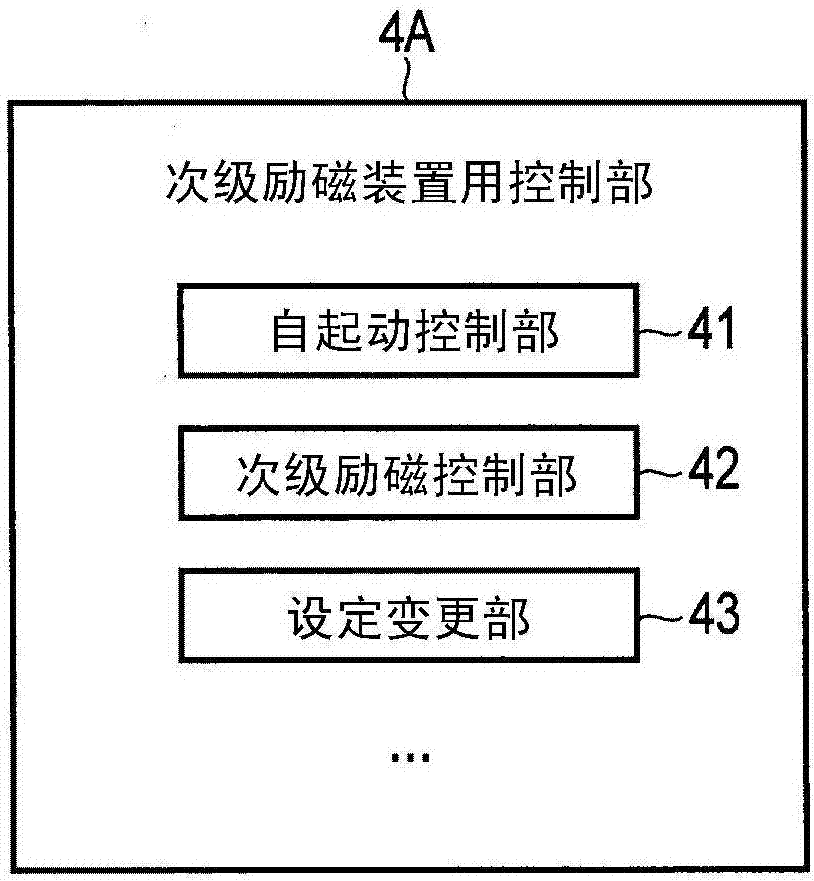

[0018] The variable-speed pumping power generation system has as the main elements: a pump wheel 1; a variable-speed generator motor 2 realized by a double-fed alternator; A self-excited secondary excitation device 3 realized by a frequency converter; a control unit 4A for the secondary excitation device that controls the AC voltage, current, frequency, and phase output from the secondary excitation device 3 and a switching device 5 , the control device 4 that the main circuit of the on-off control of 6, the driving control of the water surface depressing device 13 etc. constitutes with the control part 4B; The isolating switch (corresponding to Japanese: starting circuit breaker) 6 for the three-phase short circuit of the stator winding end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap