Ceramic mobile phone back cover and forming process thereof

A mobile phone back cover, ceramic technology, applied in the direction of phone structure, electrical components, pretreatment surface, etc., can solve the problems of inability to maintain consistency in appearance, inability to provide structural support, and fragile glass when dropped, and achieves a non-deformable, overall Strong strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

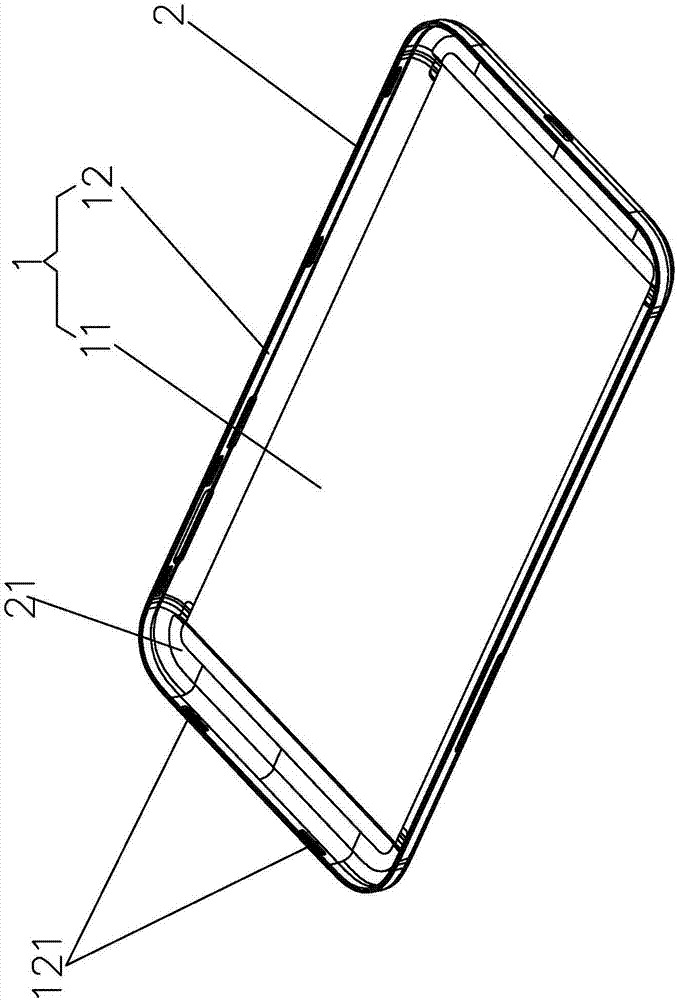

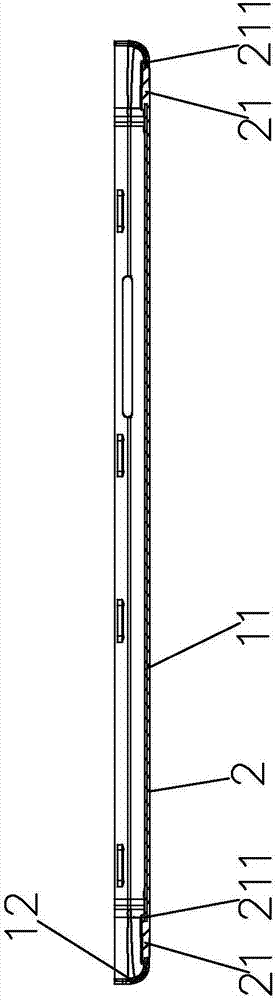

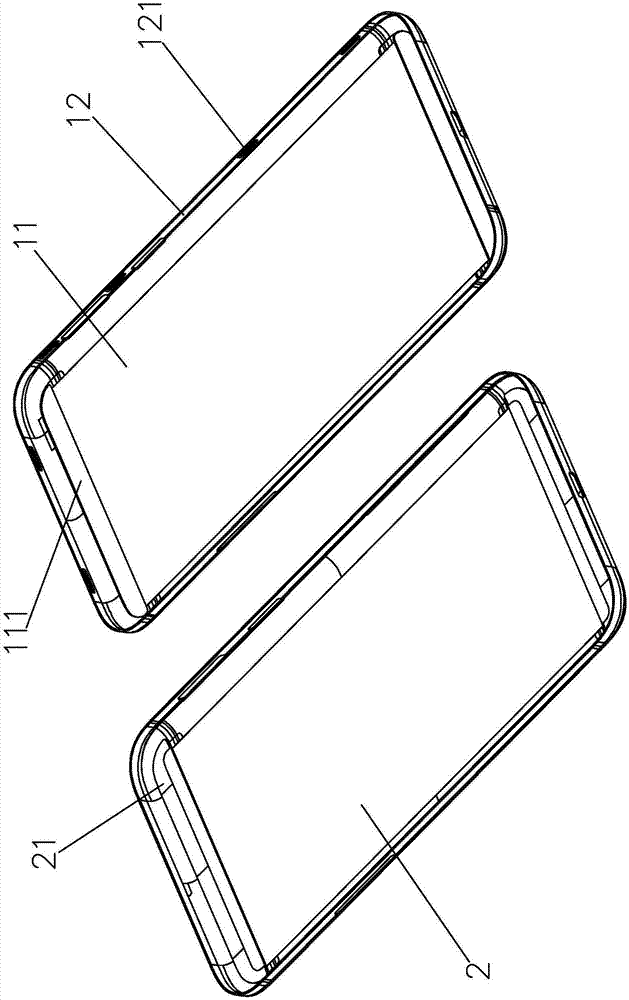

[0028] A kind of ceramic mobile phone back cover of the present invention, embodiment one, as Figure 1-3 As shown, the back cover body 1 is included. The back cover body 1 has a back plate 11 and a side wall 12 integrally formed with the back plate 11. The side wall 12 and the back plate 11 form a space for the circuit board of the mobile phone to be placed inside. A cavity (not shown in the figure), the side wall 12 is provided with a number of functional holes 121, and each functional hole 121 is respectively a sound adjustment button hole, a charging hole, an earphone hole, a sound hole, etc., the back cover body 1 The shape of the mobile phone is the same as that of the existing mobile phone back cover, and will not be repeated here.

[0029] The innovation of the present invention is that: the back cover body 1 is a metal back cover body, and the metal back cover body is made of metal materials such as aluminum, iron, stainless steel, copper or titanium, preferably alumi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap