Molecular sieve adsorption apparatus suitable for high humidity organic waste gas

An adsorption device, a technology for organic waste gas, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low organic matter adsorption efficiency, inability to effectively control moisture, and excessive organic matter concentration. Eliminate high-boiling organic matter, The effect of improving the adsorption capacity and reducing the volume of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

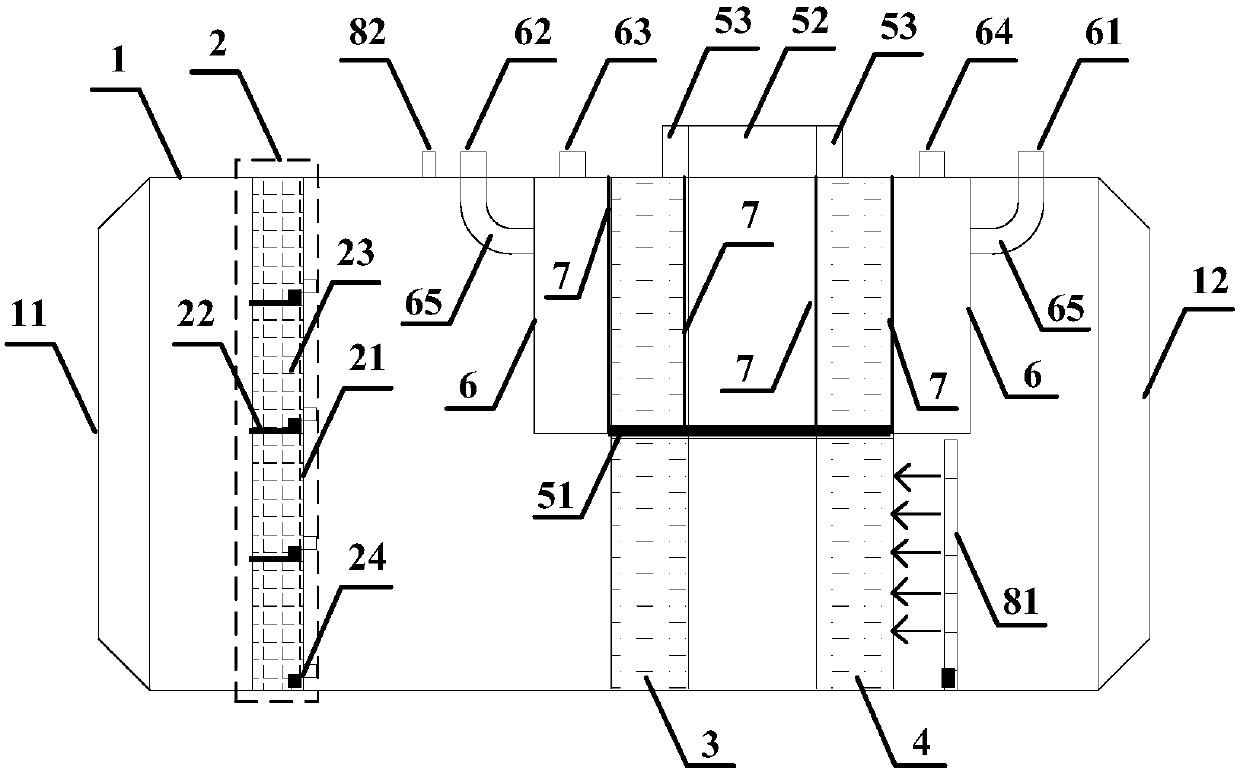

[0032] figure 1 Schematically shows the simplified structural diagram of the molecular sieve adsorption device suitable for high-humidity organic waste gas in this embodiment, as shown in figure 1 As shown, the molecular sieve adsorption device includes:

[0033] A sealed box 1, the opposite sides of the sealed box are respectively provided with a waste gas inlet 11 and a clean gas outlet 12;

[0034] A pretreatment filter 2, which is fixed in a sealed box and used to remove liquid water in the exhaust gas. The pretreatment filter includes a plate frame 21, a sieve plate 22 and a filling medium 23. The sieve plate Fixed between the plate and frame by buckle 24 (such as spring buckle);

[0035] The first molecular sieve runner 3, the first molecular sieve runner is used to remove gaseous water in the exhaust gas;

[0036] The second molecular sieve runner 4, the second molecular sieve runner is used to remove organic matter in the waste gas;

[0037] A power module, the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com