Seawater three-dimensional oil tank platform, system and construction method thereof

An underwater oil tank and oil tank technology, applied in ship construction, floating buildings, anchoring arrangements, etc., can solve the problems of high construction difficulty, high cost, low stability, etc., and achieve shortened construction period and high utilization rate. , the effect of reducing safety and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

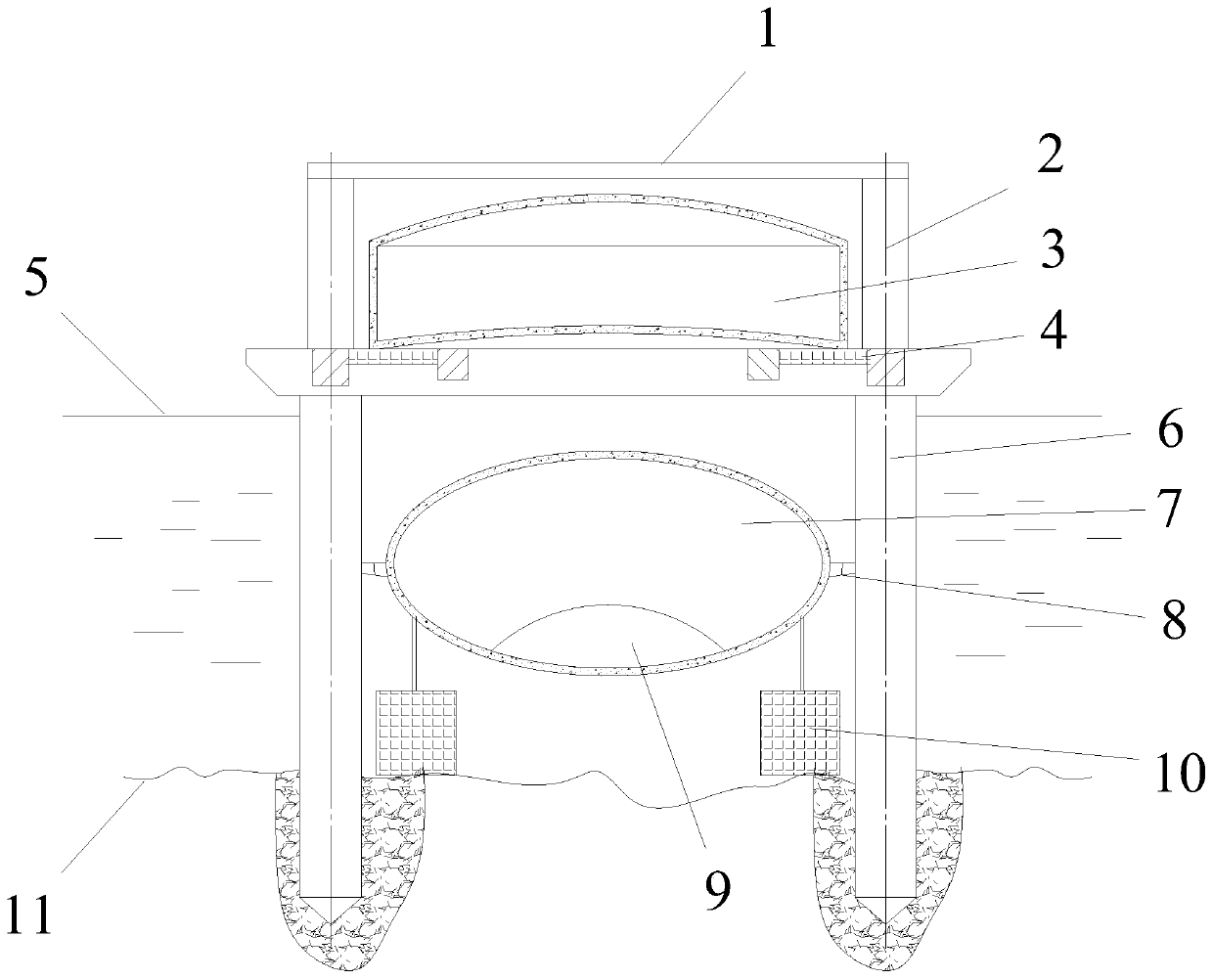

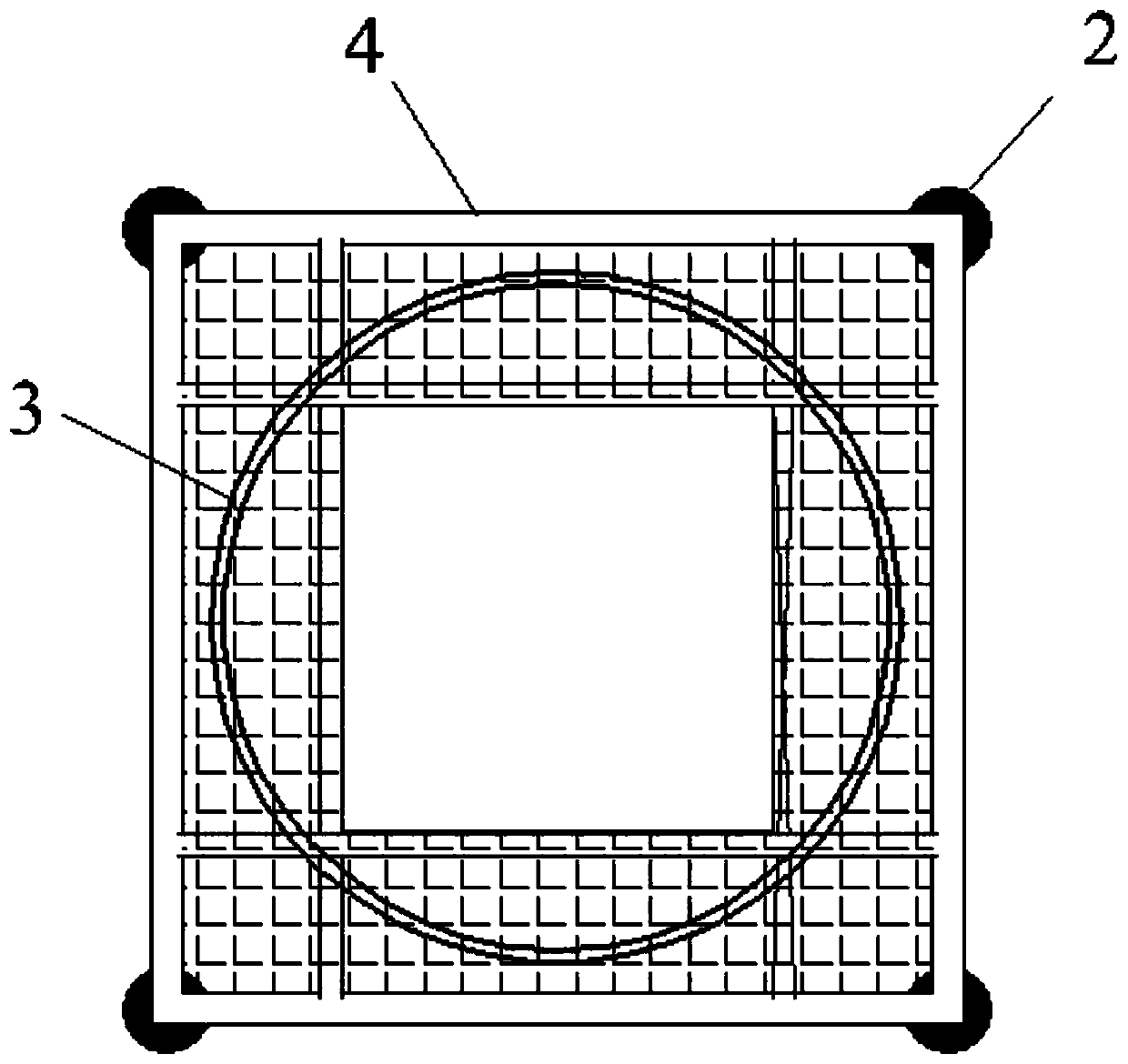

[0054] Such as Figure 1-3 As shown, a seawater three-dimensional oil tank platform includes at least three piles or buoyancy cylinders 6 connected to the seabed 11, and also includes an underwater oil tank 7 connected between all the piles or buoyancy cylinders 6, and The support frame 4 that is arranged on the top of all the piles or buoyancy cylinders 6, above the support frame 4 is provided with an oil tank 3 on the water, and the underwater oil tank 7 is connected with several anchors on the seabed or seabed 11 Gravity anchor 10, the underwater oil tank 7 is located below the sea level 5, the above water oil tank 3 is located above the sea level 5, and the cavities of the underwater oil tank 7 and the underwater oil tank 7 communicate with each other.

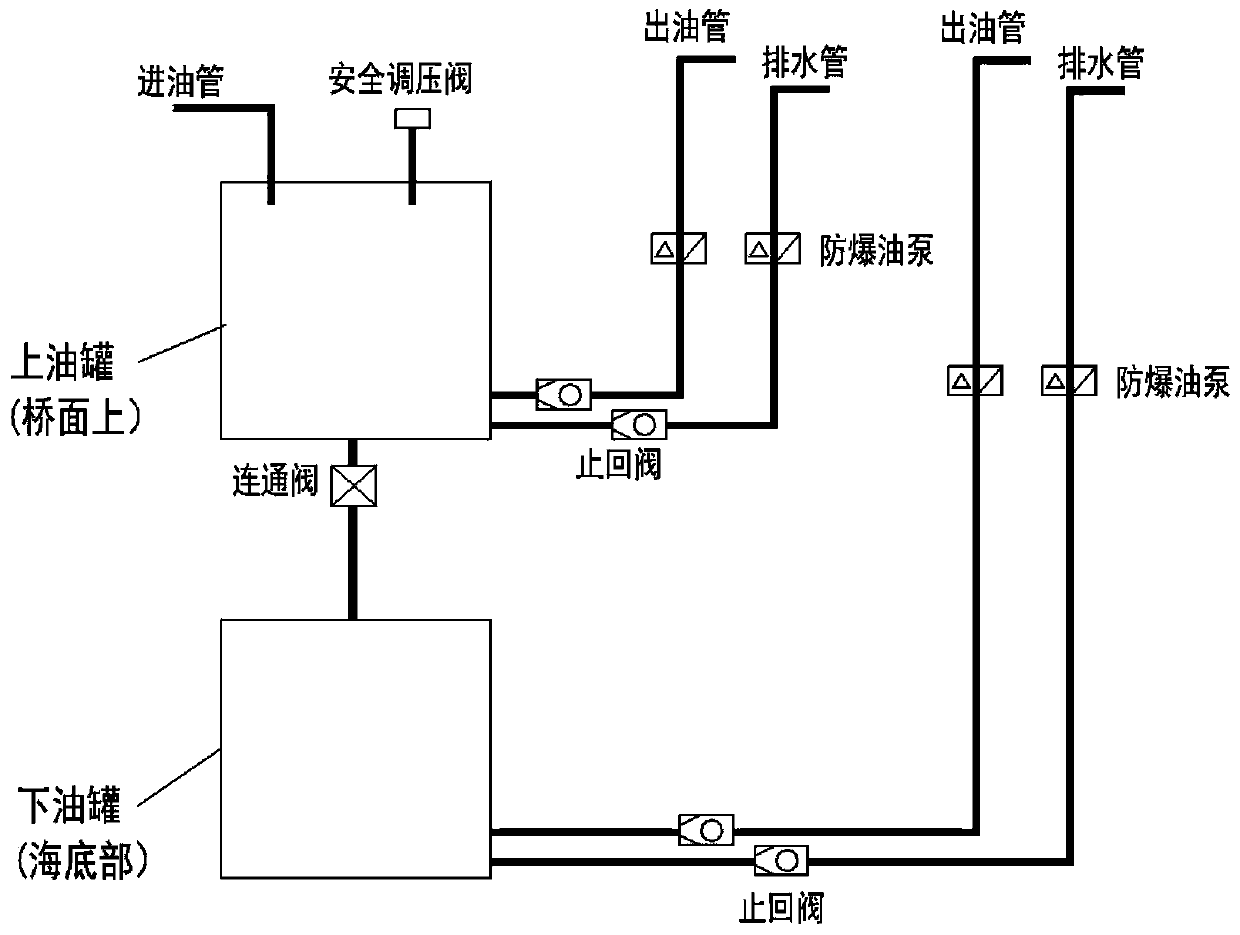

[0055] Specifically, such as figure 2 As shown, the above-mentioned water oil tank 3 and the underwater oil tank 7 are connected by pipelines, and switch valves are arranged between the pipelines; each unit of the underw...

Embodiment 2

[0066] Such as Image 6 As shown, Embodiment 2 also provides a seawater three-dimensional oil tank system, including several seawater three-dimensional oil tank platforms as in Embodiment 1, and all seawater three-dimensional oil tank platforms are connected in parallel to form a row or Arrayed seawater three-dimensional oil tank system. The seawater three-dimensional oil tank system consists of several seawater three-dimensional oil tank platforms connected in parallel to form a row or array seawater three-dimensional oil tank system, which can effectively meet the needs of actual submarine oil and gas development and oil and gas storage, and facilitate construction and efficient use of water. The adjacent connection positions of the two platforms can share piles or buoyancy cylinders 6 .

[0067] The basic structure and construction method of the seawater three-dimensional oil tank system are similar to those of Embodiment 1, and the same parts will not be repeated here. ...

Embodiment 3

[0069] The present invention also provides a construction method of a seawater three-dimensional oil tank platform, that is, a construction method of a seawater three-dimensional oil tank platform in Embodiment 1, comprising the following steps:

[0070] Step 1, install piles or buoyancy cylinders 6, float all the piles or buoyancy cylinders 6 required by the platform to the site, drive all the piles or buoyancy cylinders 6 into the seabed 11 and fix them, and The piles or buoyancy cylinders 6 are located at the part above the sea level 5 and the support frame 4 is installed, and all the piles or buoyancy cylinders 6 are connected to each other;

[0071] Step 2: Install the underwater oil tank 7, first float the gravity anchor 10 under the platform, first install the underwater gravity anchor 10 and the reserved anchor chain, and then float the underwater oil tank 7 under the platform, stretch Exit the top pressure rod 8, stop when it reaches the surface of the pile or buoyanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com