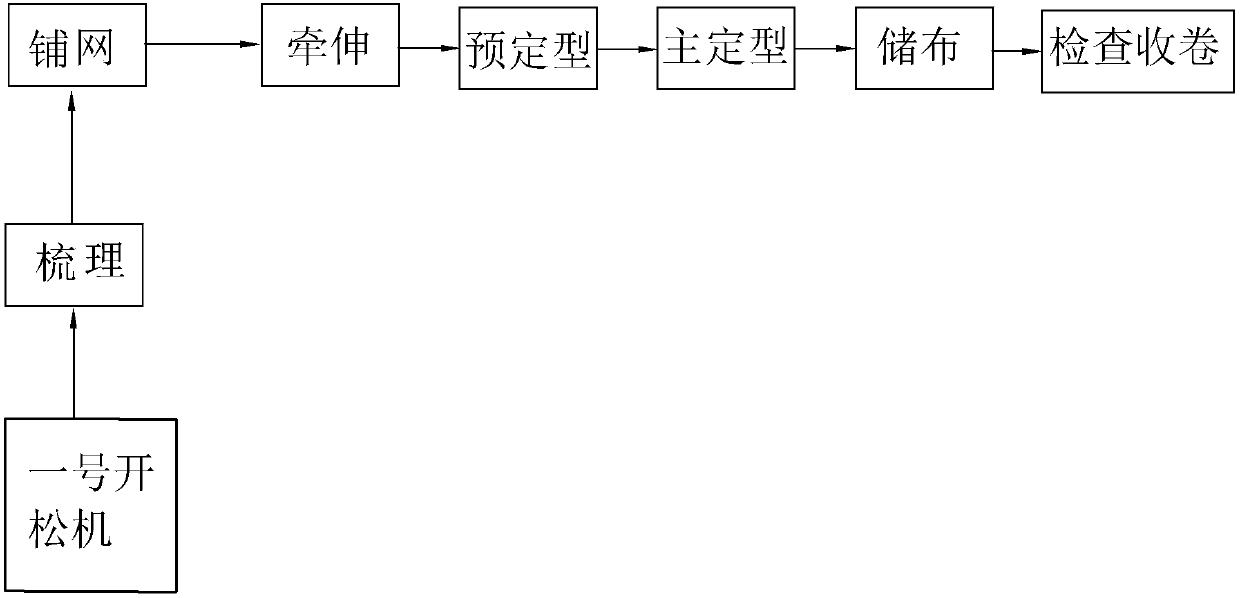

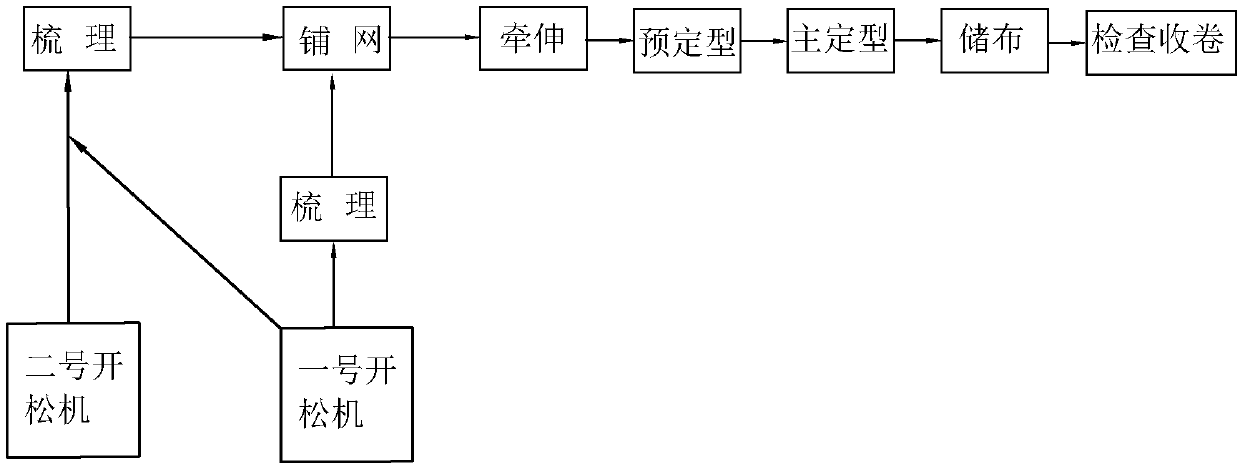

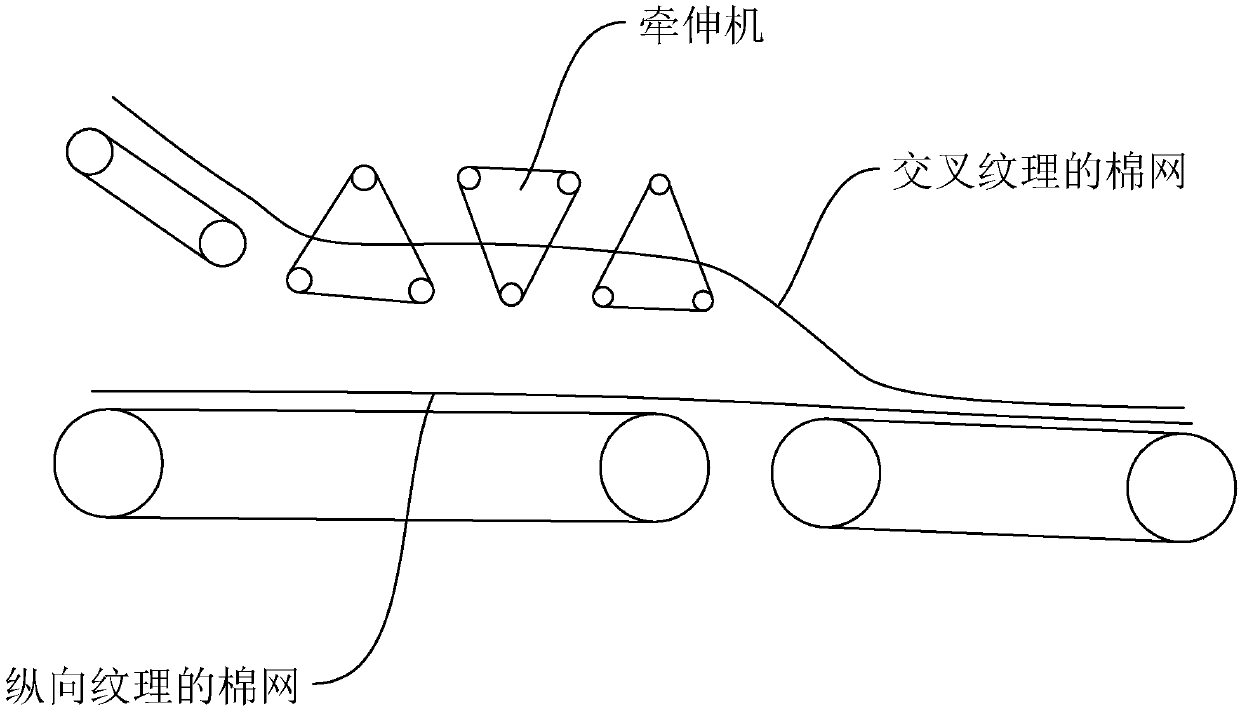

Light and high-strength non-woven fabric production process

A production process and technology of non-woven fabrics, applied in the direction of non-woven fabrics, textiles and papermaking, etc., which can solve the problems of heavy non-woven bags, reduced strength, easy delamination, etc., and achieve light and uniform thickness and uniform load-bearing capacity , regular texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] Embodiment 2: The difference from Embodiment 1 is that in step S1, PET / PET is selected, and the temperature of the hot rolling mill in step S5 is 110°C, which can produce a fabric with a hard hand, light and high strength, which is suitable for passing super Sonic stitching, and since the melting point of PET is 110°C, the temperature of the hot rolling mill is controlled at 110°C to ensure that PET / PER can be melted and bonded during hot rolling.

Embodiment 3

[0051] Embodiment three: the difference with embodiment one is: select PET / PP in step S1, wherein PET weight ratio is 70%-90%, PP weight ratio is 10%-30%, the temperature of hot rolling mill is 150°C, choose PET / PP composite material for mixed laying, and the PP weight accounts for 10%-30%, the produced fabric is PET on one side and PP on the other side. When making a packaging bag, the material is One side of the PP is in contact with each other, and heat sealing can be achieved through a sealing machine, and the heat-sealed packaging bag has a firm structure and is not easy to damage. The melting point of PP is 150°C, so when the cloth enters the hot rolling machine at 150°C, PP melts and the other The fibers are bonded into sheets.

Embodiment 4

[0052] Embodiment four: the difference with embodiment one is: select PET / PERPE in the step S1, wherein the weight ratio of PET is 70%-90%, the weight ratio of PETPE is 10%-30%, the hot rolling mill The temperature is 130°C, PETPE has a skin-core structure, the outer layer is PE with a lower melting point, and the inner layer is PET with a higher melting point, so that the melted PE can be used as an adhesive to bond and connect the fibers; the melting point of PE When the cotton web enters the hot rolling mill at 130°C, PE melts and acts as a binder to bond the fibers into a sheet of fabric without adding other binders, thereby realizing the lightweight of the fabric and making the fabric Thinner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com