Structure and construction method of T-beam prefabricated field pedestals

A technology of prefabrication yards and pedestals, which is applied in the direction of infrastructure engineering, manufacturing tools, auxiliary molding equipment, etc. It can solve the problems of pedestals without anti-leakage slurry, foundation subsidence, and inability to discharge, so as to achieve convenient adjustment of height difference and accurate placement , the effect of preventing template offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

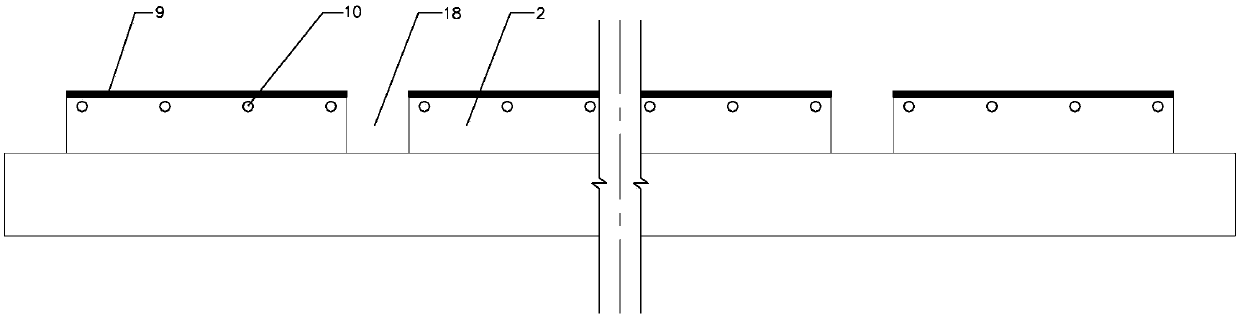

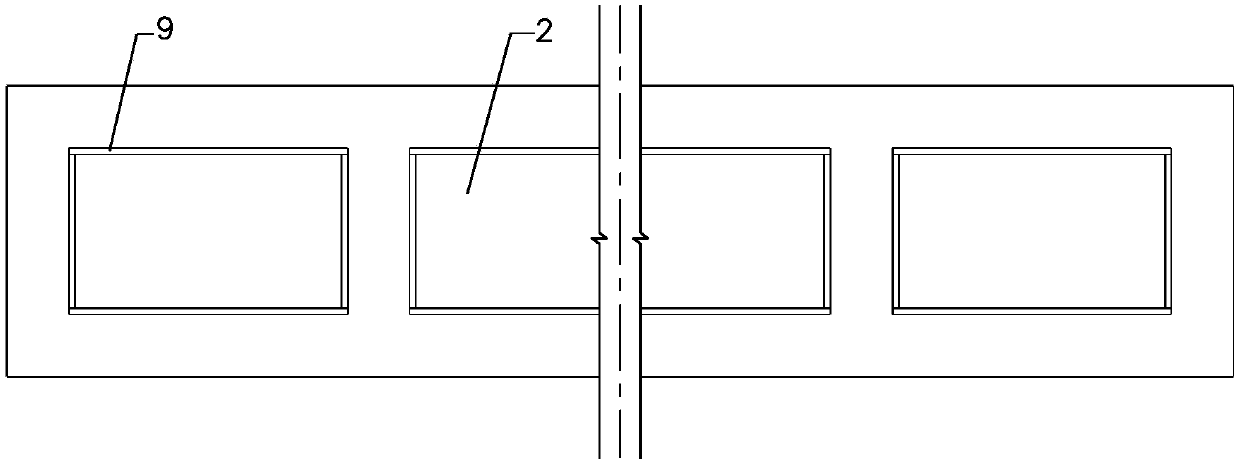

[0031] Such as Figure 1-Figure 8 As shown, a T-beam prefabricated field pedestal structure is provided with an anti-leakage slurry device at the upper end of the pedestal 2; on the top of the pedestal 2, a pipeline 10 is pre-embedded for the T-beam side formwork tension bolts; Bottom mold brackets are provided at the suspension beams 18 between the pedestals 2; drainage grooves are provided on the basis of the pedestals 2.

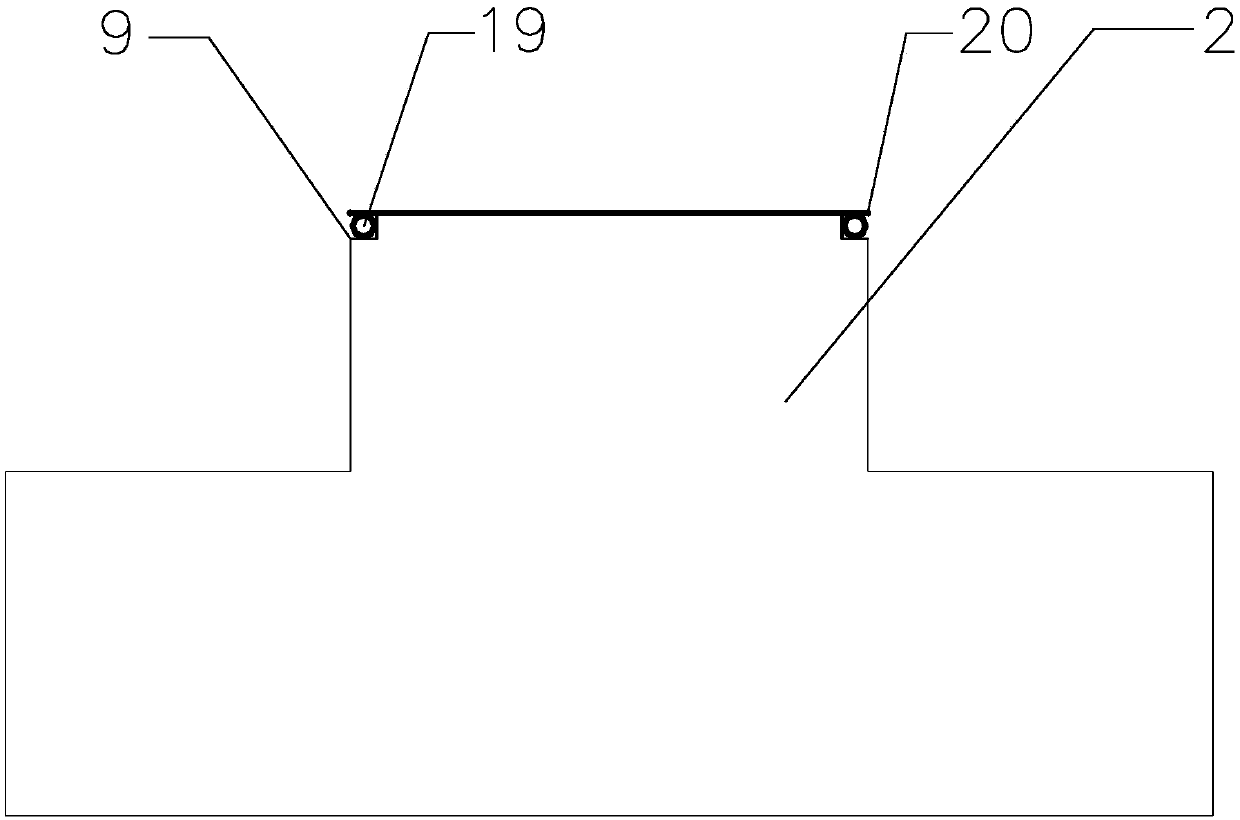

[0032] The anti-leakage slurry device includes a ring support beam 9 and a sealing rubber hose 19. The ring support beam 9 is welded end to end by angle steel on the top of the pedestal 2, and the ring support beam 9 forms a rubber hose on the top of the pedestal 2. The installation groove, the sealing rubber hose 19 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com