Rotary electrostatic fume waste gas purifier

An exhaust gas purifier and oil fume technology, which is applied in the directions of external electrostatic separator, oil fume removal, electrostatic effect separation, etc., can solve the problems of mutual interference, small anode area, oil fume adhesion, etc., and achieves the effect of simple manufacture and reduced cleaning frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

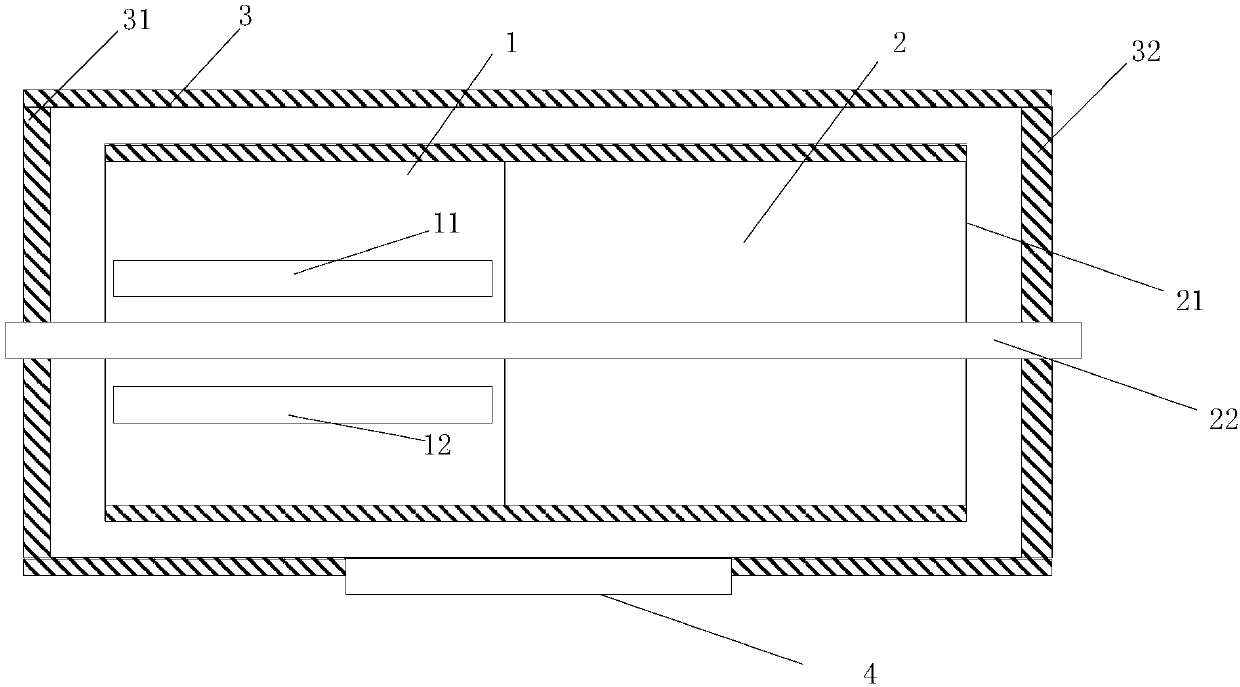

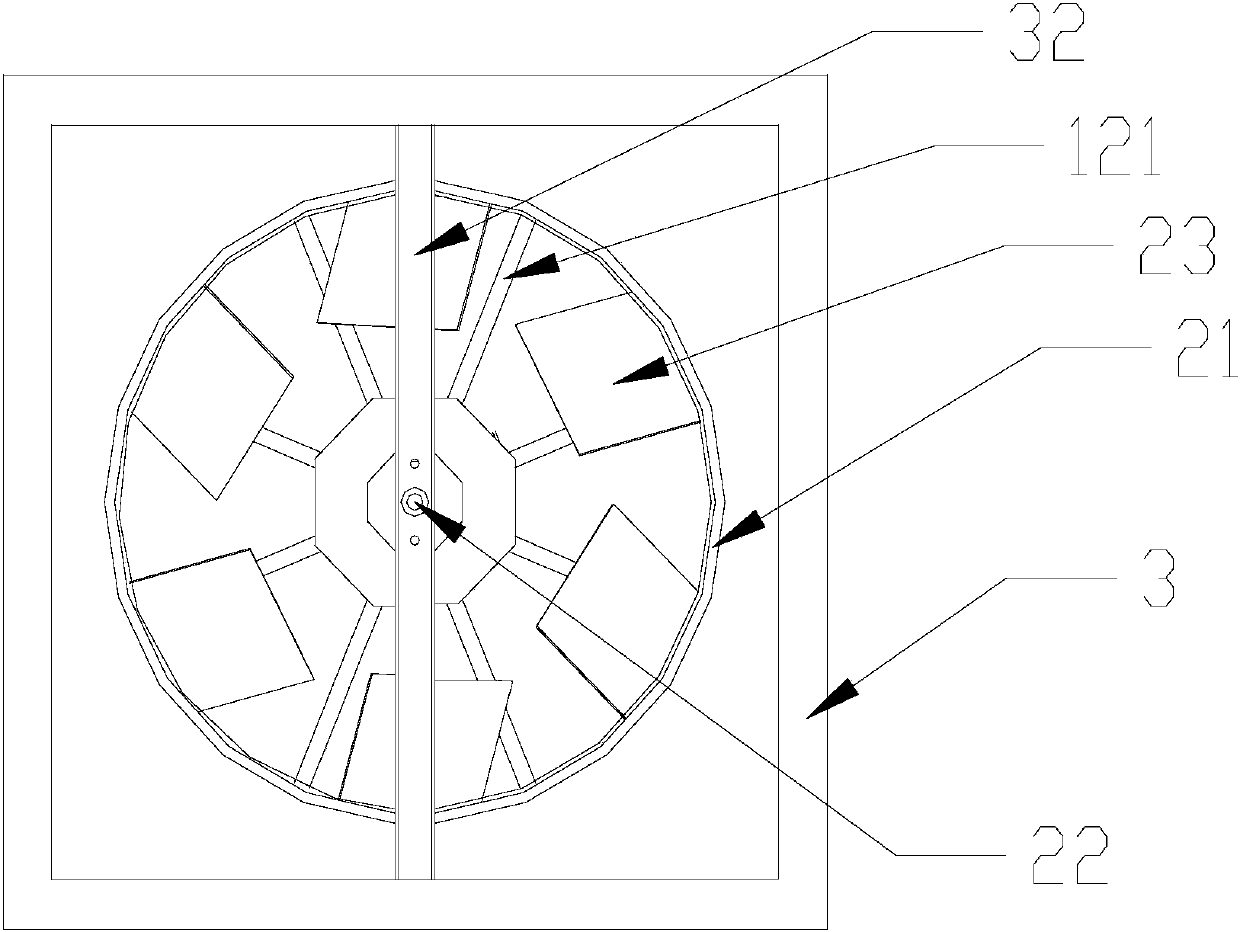

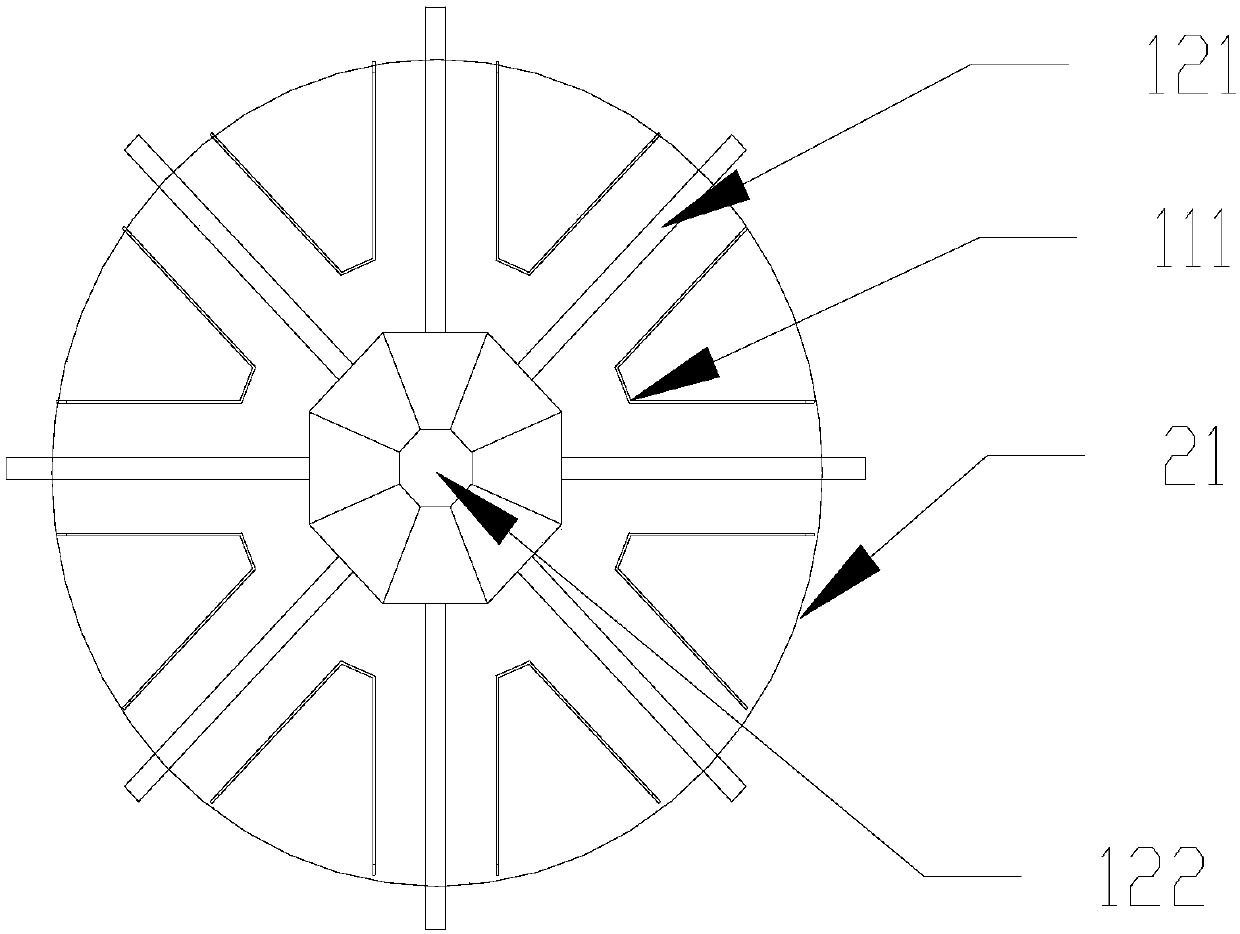

[0033] refer to figure 1 , the embodiment of the present invention proposes a rotary electrostatic oil fume exhaust gas purifier, including an ionization area 1 and a collection area 2, the ionization area 1 includes a first electrode 11 and a second electrode 12, and the collection area 2 includes a drum body 21, The drum body 21 is connected to the first electrode 11;

[0034] When the purifier is working, the drum body 21 is in a rotating state.

[0035] In this embodiment, the rotary electrostatic oil fume exhaust gas purifier is used in conjunction with a fan. The fan can be installed at the end of the duct, while the purifier is installed at the air inlet. This minimizes the build-up of soot pollutants in the soot exhaust in the ductwork.

[0036] When the purifier is working, the fume exhaust gas first pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com