Submerged arc furnace adjusting and control method

A technology of submerged arc furnace and charge, applied in the field of submerged arc furnace control, can solve the problems of long time consumption, unstable production of submerged arc furnace, low output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

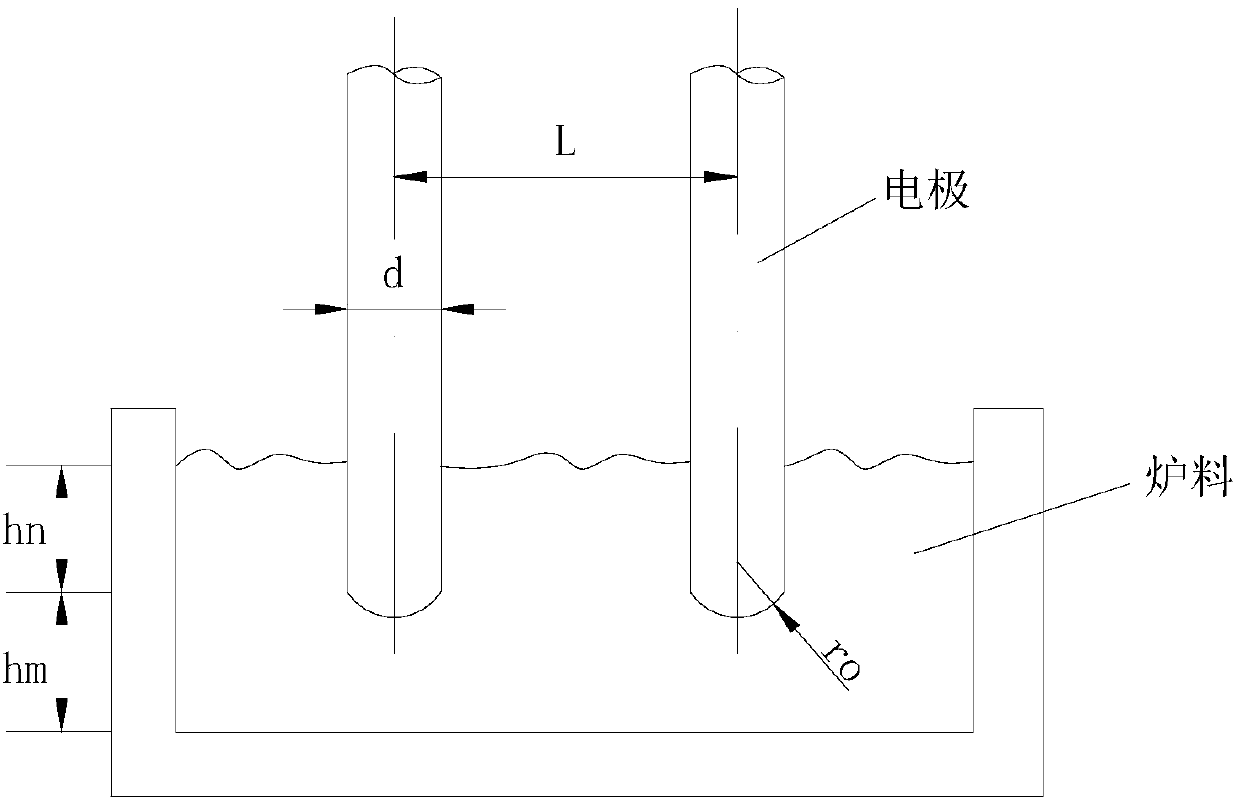

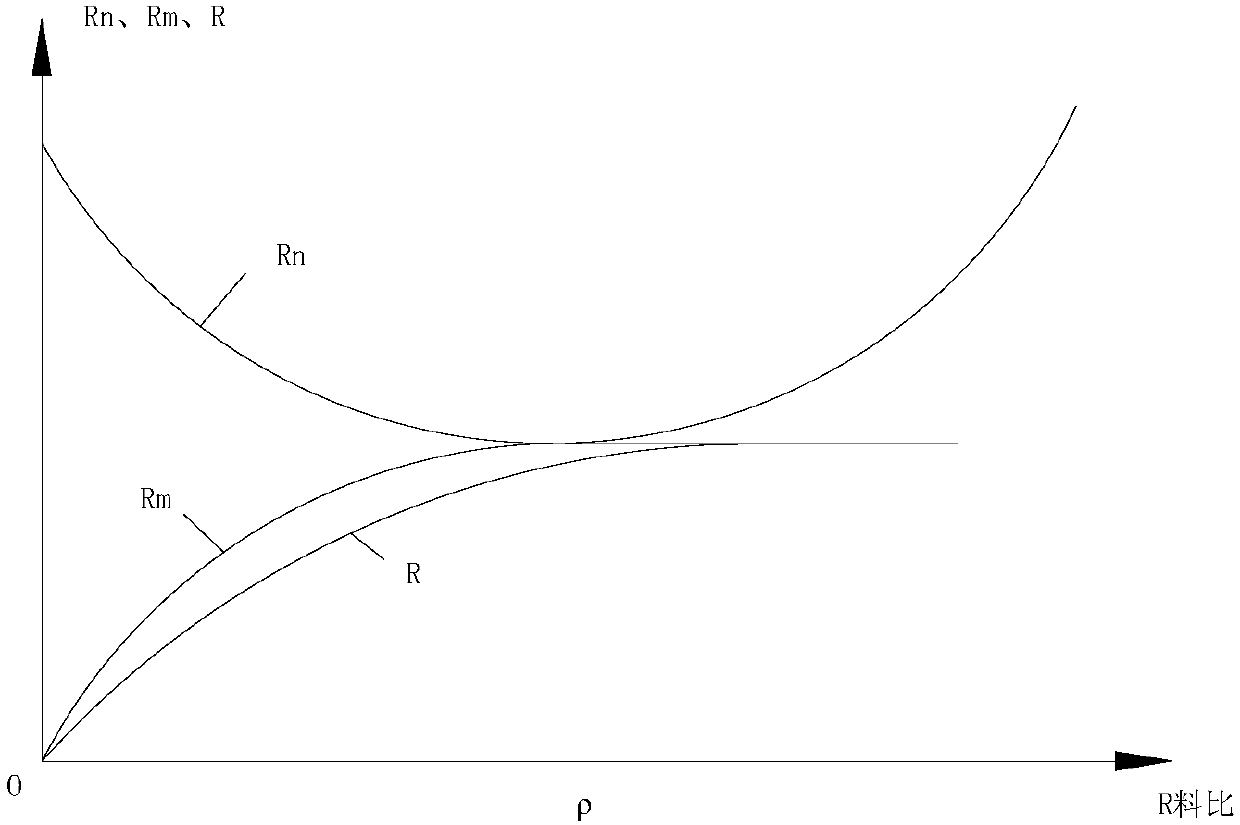

[0100] There are two circuits connected in parallel in the melting pool of the submerged arc furnace, that is, resistance heat and arc heat. Maximeco divides the resistance system and arc system in the submerged arc furnace smelting according to their different proportions. Different smelting varieties have their own suitable conditions. proportion. How to control the submerged arc furnace to achieve this suitable ratio?

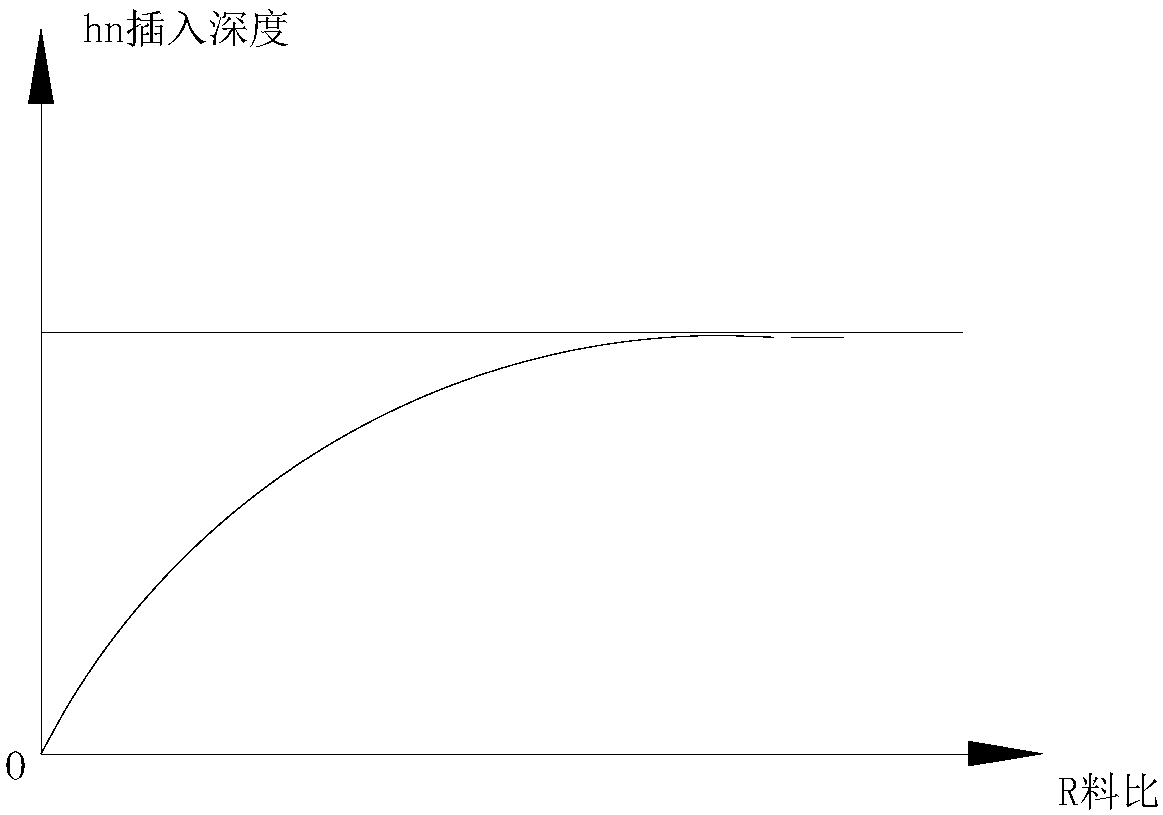

[0101] 1. Charge specific resistance R 料比 Functional relationship with heat partition coefficient

[0102] heat partition coefficient

[0103] Rn≥Rm When Rn=Rm, C is the maximum value, namely At this time, the arc power is equal to the resistance power. According to charge specific resistance R 料比 The functional relationship between the star-shaped resistance and the angular resistance, and the functional relationship between the specific resistance of the charge and the heat distribution coefficient are derived.

[0104] Namely: C=a·R 料比 2 +b·R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com