Full penetration welding method for U ribs

A welding method and full penetration technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as shortening the service life of bridges, stress concentration of weld bulges, fatigue cracks, etc., and prolong the service life of bridges. The effect of avoiding stress concentration and improving stress characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

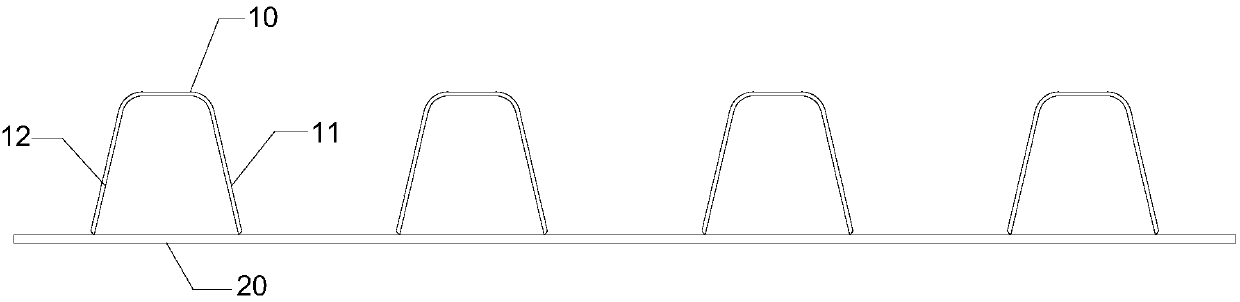

[0056] Taking the high-strength steel plate with U-rib 10 plate thickness t of 8mm and panel 20 thickness T of 16mm as an example, U-rib 10 fillet weld single-side welding double-side forming full penetration welding.

[0057] 1. Preparation before welding

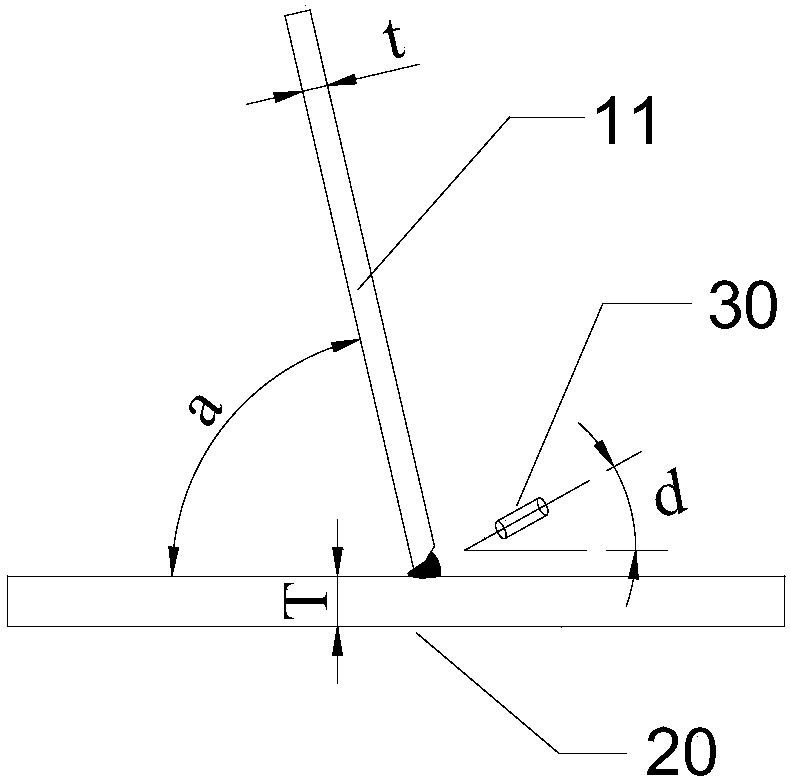

[0058] according to image 3 Groove processing and assembly are completed, the U-rib 10 plate thickness t is 8mm, the panel 20 thickness T is 16mm, and the steel plate material is Q345qE. The angle a between the rib angle 11 on one side of the U rib 10 and the panel 20 is 75°, the groove angle b on the outer side of the weld is 50°, the gap between the root and the blunt edge is less than 1mm during assembly, and the groove and the surrounding 20mm are removed before welding. Rust, oil stains.

[0059] 2. Welding adjustment

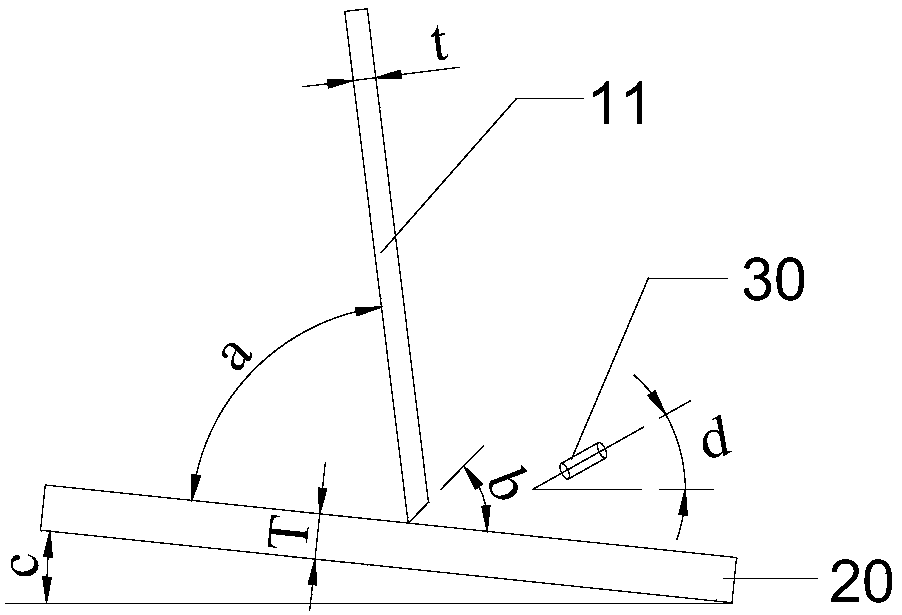

[0060] Hoist the workpiece (assembled U-rib 10 and panel 20) onto the tire frame, adjust the tire frame to form an 8° reverse inclination c (that is, the rib foot 12 on the other side opposite to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com