Low-density high-strength niobium alloy bar and preparing method thereof

A niobium alloy, low-density technology, applied in the field of low-density and high-strength niobium alloy bars and their preparation, can solve the problems of high preparation cost, uneven matrix composition, and lack of niobium alloy ingots, etc., and achieves high room temperature and high temperature. Mechanical properties, excellent internal structure, and the effect of eliminating intragranular segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

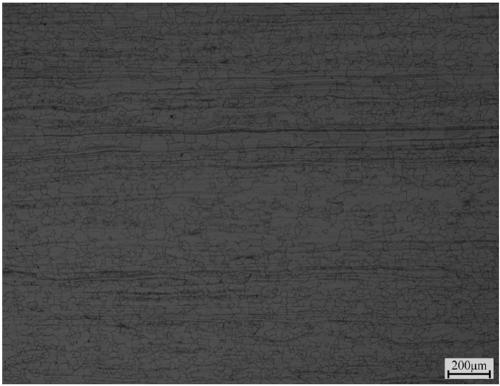

Image

Examples

Embodiment 1

[0030] The low-density high-strength niobium alloy bar of this embodiment consists of the following components by mass percentage: Ti 30%, Al 5%, W 4.5%, Cr 6%, Zr 1.1%, Mo 0.5%, Y 0.06%, and the balance is Nb and unavoidable impurities; the density of the low-density high-strength niobium alloy rod is 6.89g / cm 3 , The tensile strength at room temperature is 1170MPa, the elongation at room temperature is 20%, and the tensile strength at 1200°C is 178MPa.

[0031] The preparation method of the low-density high-strength niobium alloy bar of the present embodiment comprises the following steps:

[0032] Step 1. Put 52.3kg of pure niobium shavings, 30kg of zero-grade sponge titanium, 0.88kg of aluminum beans, 6kg of high-purity chromium, 9kg of AlW50, 0.623kg of AlMo80, 0.06kg of yttrium powder, and 1.1kg of nuclear-grade zirconium sponge into the pressing mold and ensure that zero-grade sponge titanium, aluminum beans, high-purity chromium, AlW50, AlMo80, yttrium powder, and nuc...

Embodiment 2

[0039] The low-density high-strength niobium alloy bar of this embodiment consists of the following components by mass percentage: Ti 29.5%, Al 4.5%, W 4%, Cr 5.5%, Zr 1%, Mo 0.4%, Y 0.08%, the balance It is Nb and unavoidable impurities; the density of the low-density high-strength niobium alloy rod is 6.8g / cm 3 , The tensile strength at room temperature is 1150MPa, the elongation at room temperature is 18%, and the tensile strength at 1200°C is 100MPa.

[0040] The preparation method of the low-density high-strength niobium alloy bar of the present embodiment comprises the following steps:

[0041] Step 1. Put 55kg of pure niobium shavings, 29.5kg of zero-grade titanium sponge, 0.4kg of aluminum beans, 5.5kg of high-purity chromium, 8kg of AlW50, 0.5kg of AlMo80, 0.08kg of yttrium powder, and 1kg of nuclear-grade zirconium sponge into the pressing mold and ensure that zero-grade sponge titanium, aluminum beans, high-purity chromium, AlW50, AlMo80, yttrium powder, and nuclea...

Embodiment 3

[0047] The low-density high-strength niobium alloy bar of this embodiment consists of the following components by mass percentage: Ti 30.5%, Al 5.5%, W 5%, Cr 7.5%, Zr 1.3%, Mo 0.7%, Y 0.05%, the balance It is Nb and unavoidable impurities; the density of the low-density high-strength niobium alloy rod is 7g / cm 3 , The tensile strength at room temperature is 1200MPa, the elongation at room temperature is 16%, and the tensile strength at 1200°C is 180MPa.

[0048] The preparation method of the low-density high-strength niobium alloy bar of the present embodiment comprises the following steps:

[0049] Step 1. Put 49.5kg of pure niobium shavings, 30.5kg of zero-grade sponge titanium, 0.33kg of aluminum beans, 7.5kg of high-purity chromium, 10kg of AlW50, 0.87kg of AlMo80, 0.05kg of yttrium powder, and 1.3kg of nuclear-grade zirconium sponge into the In the pressing mold, and ensure that zero-grade sponge titanium, aluminum beans, high-purity chromium, AlW50, AlMo80, yttrium pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com