Conveying device for wire-material dispensing production line

A conveying device and production line technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of high labor intensity of workers, improve dispensing efficiency, shorten the time of item transfer, and shorten the time of dispensing glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

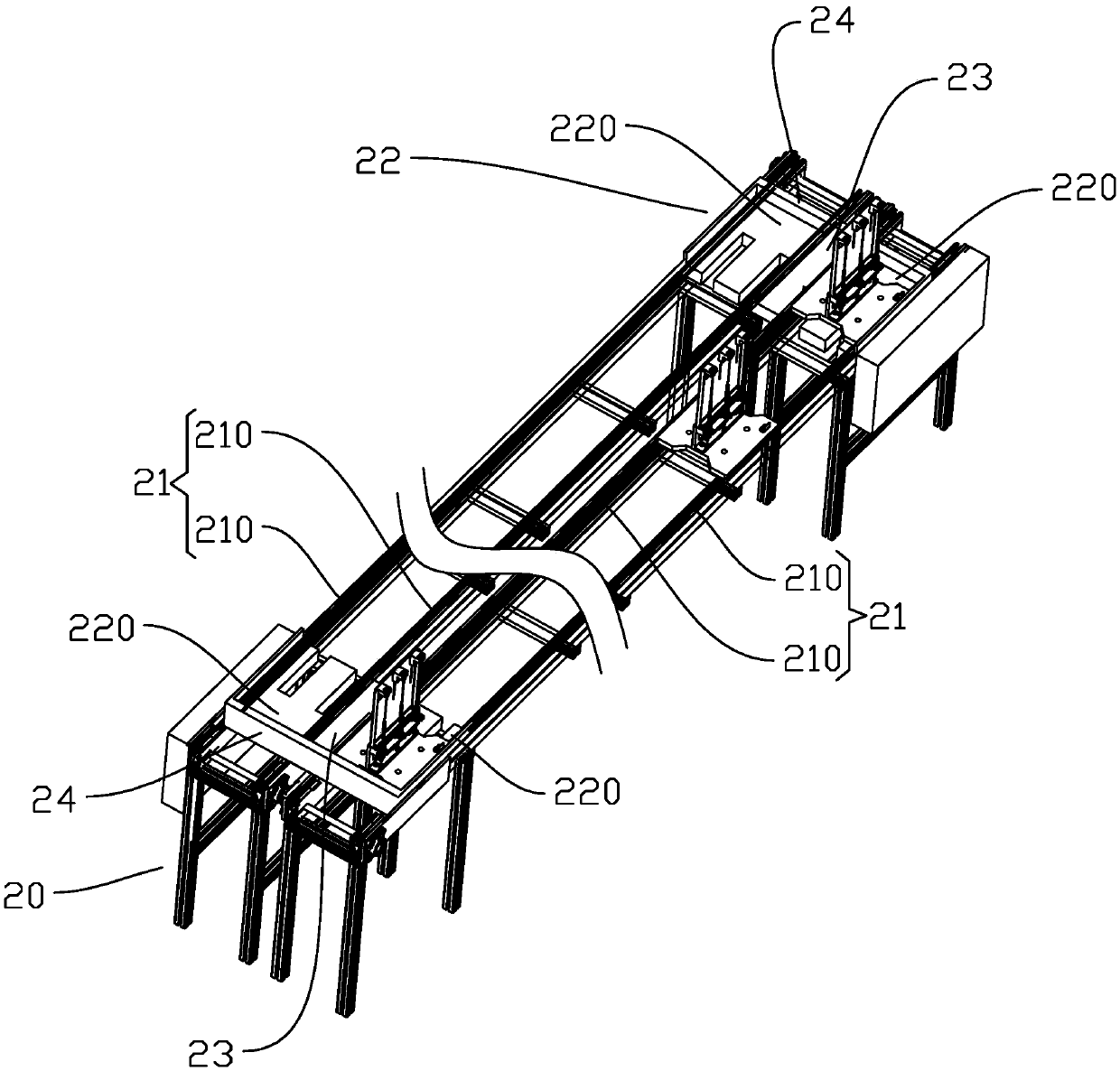

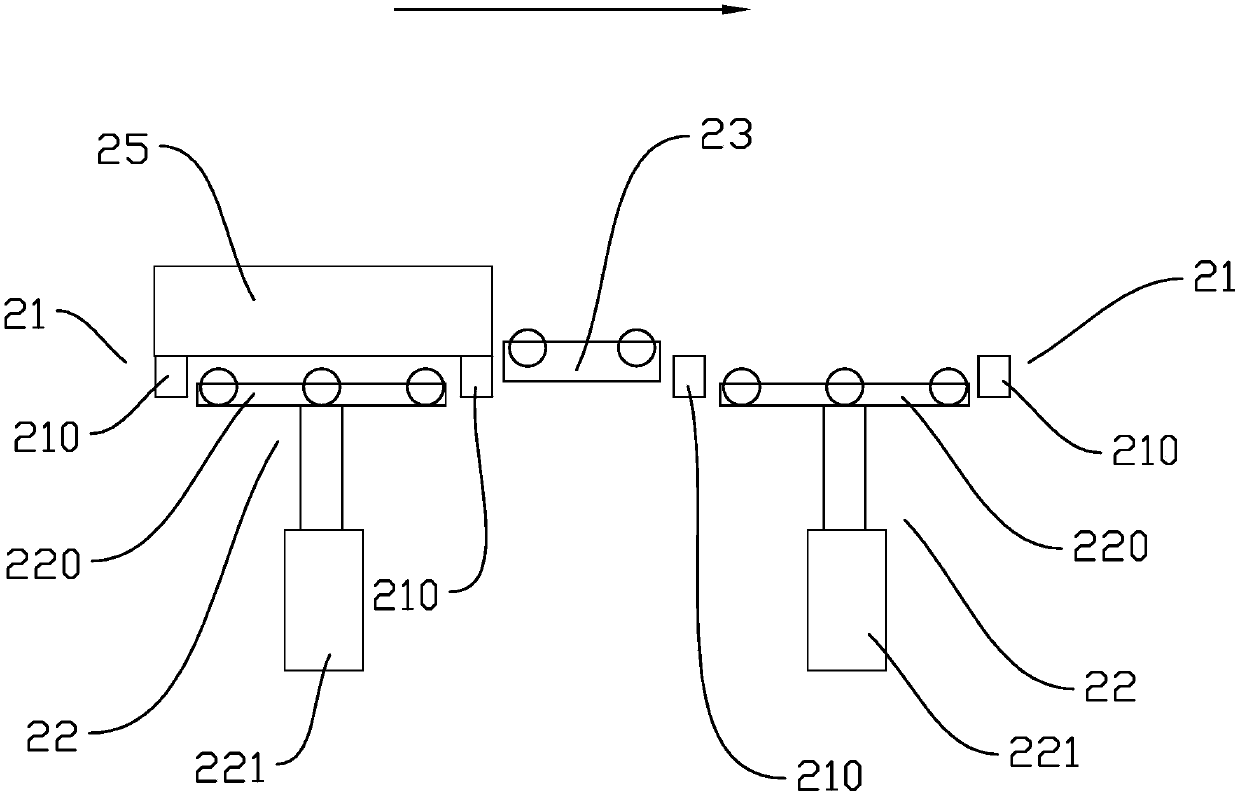

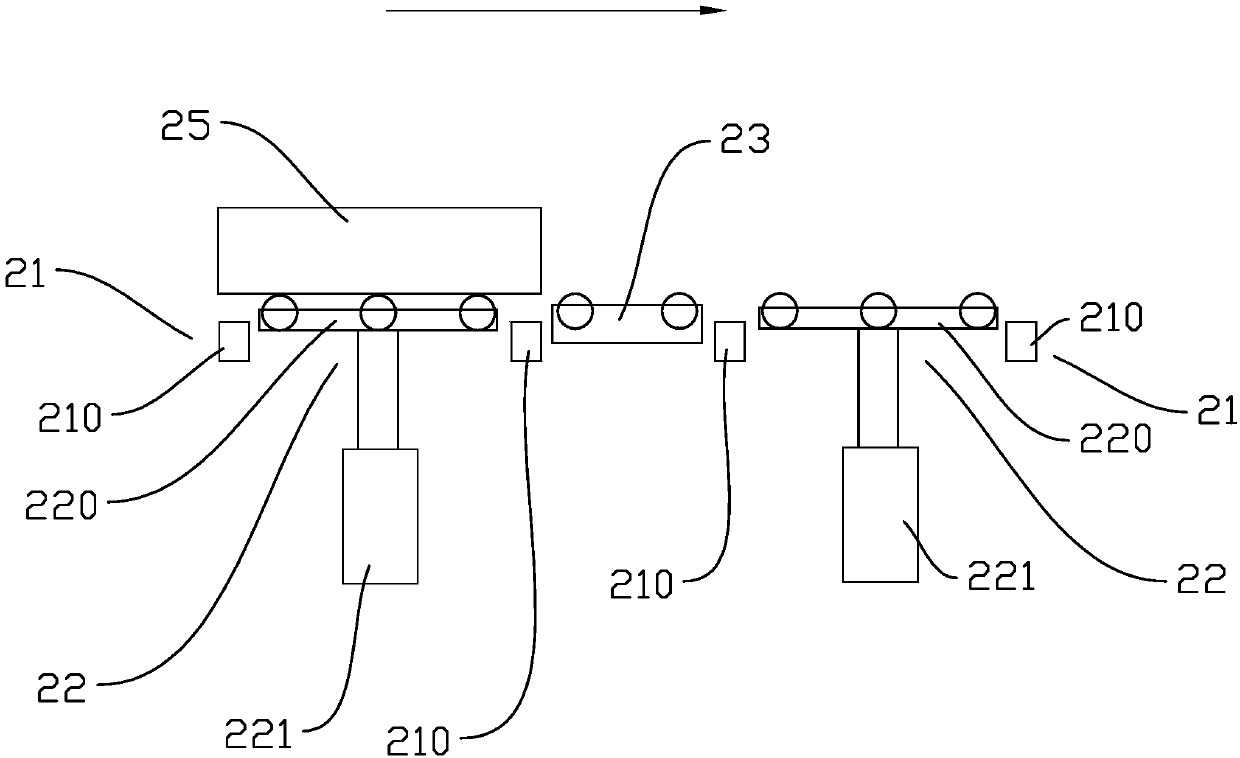

[0025] refer to Figure 1 to Figure 4 , a conveying device for a wire dispensing production line, comprising a frame 20; Arrangement, two groups of conveying mechanisms 21 convey articles 25 in opposite directions. In the present invention, preferably, the two groups of conveying mechanisms 21 are arranged parallelly on the frame 20, and the frame 20 is also provided with Two sets of transfer mechanisms 22, the two sets of transfer mechanisms 22 are respectively arranged at the front and rear ends of the frame 20, and the transfer mechanisms 22 are used to transfer the articles 25 from one set of conveying mechanisms 21 to the other set of conveying mechanisms 21 superior.

[0026] Since the present invention sets a group of transfer mechanisms 22 respectively at the front and rear ends of the frame 20, the articles 25 conveyed on the conveying mechanism 21 can be transferred to another group of conveying mechanisms 21 through the transfer mechanism 22, thus abandoning the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com