Discharge roller of a stretching machine

A technology of discharge roller and stretching machine, which is applied in the direction of rolling out thin soft materials, thin material handling, transportation and packaging, etc. It can solve problems such as wrinkles and uneven cloth, and improve the ability to recover from deformation, which is not easy The effect of slipping and increasing the axial force component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

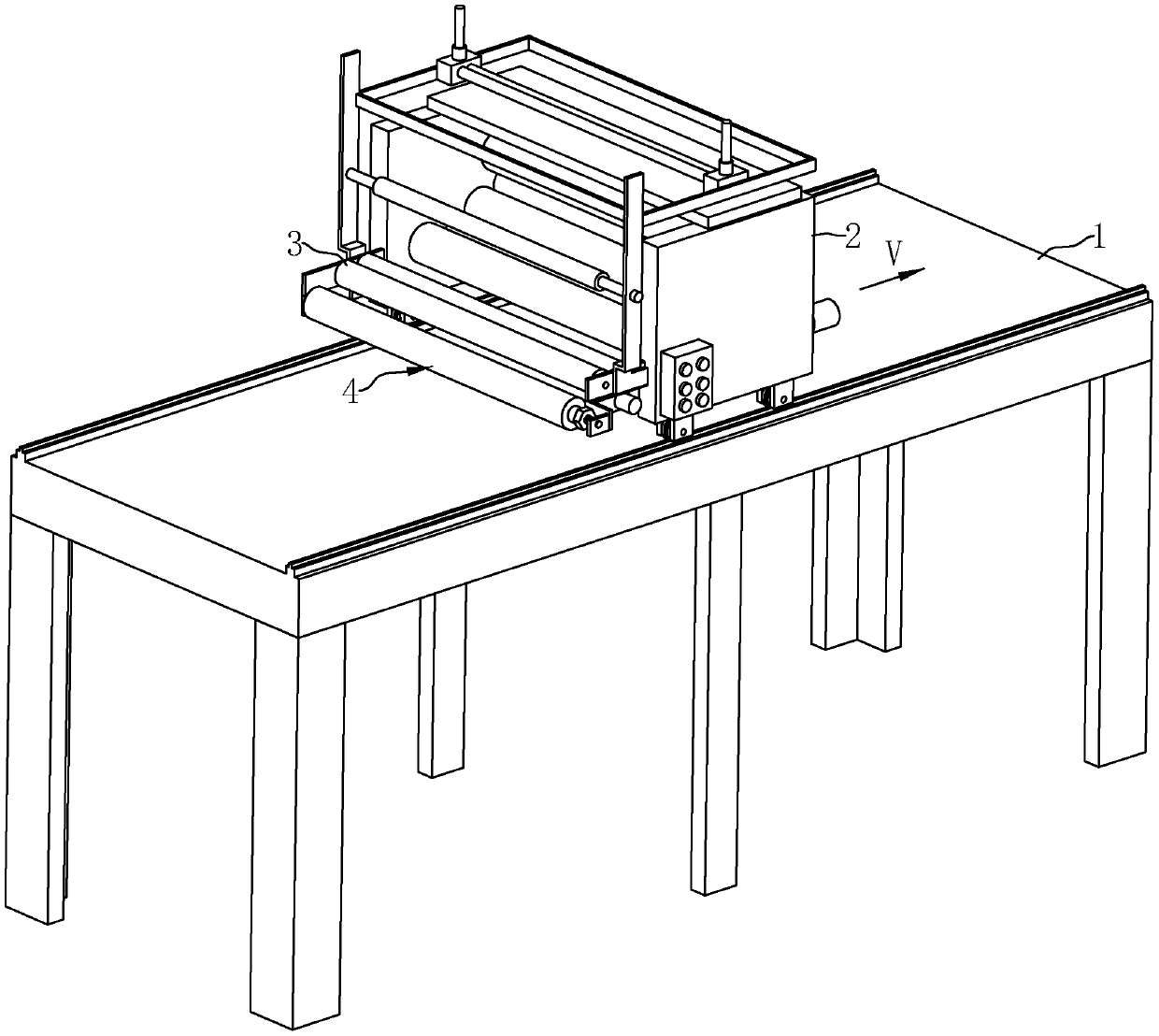

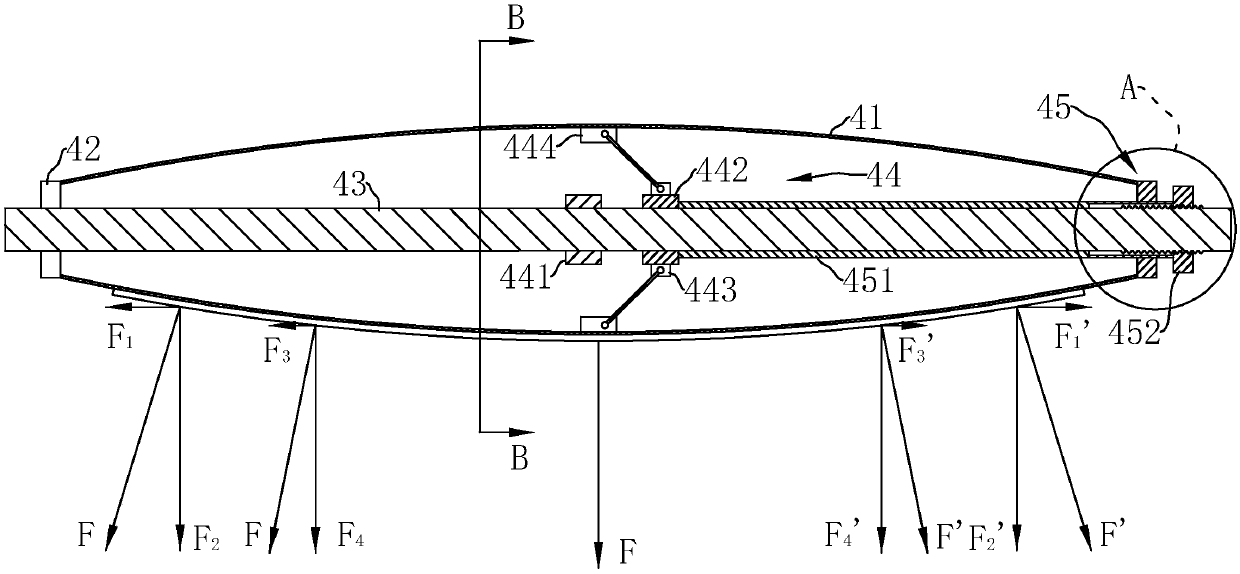

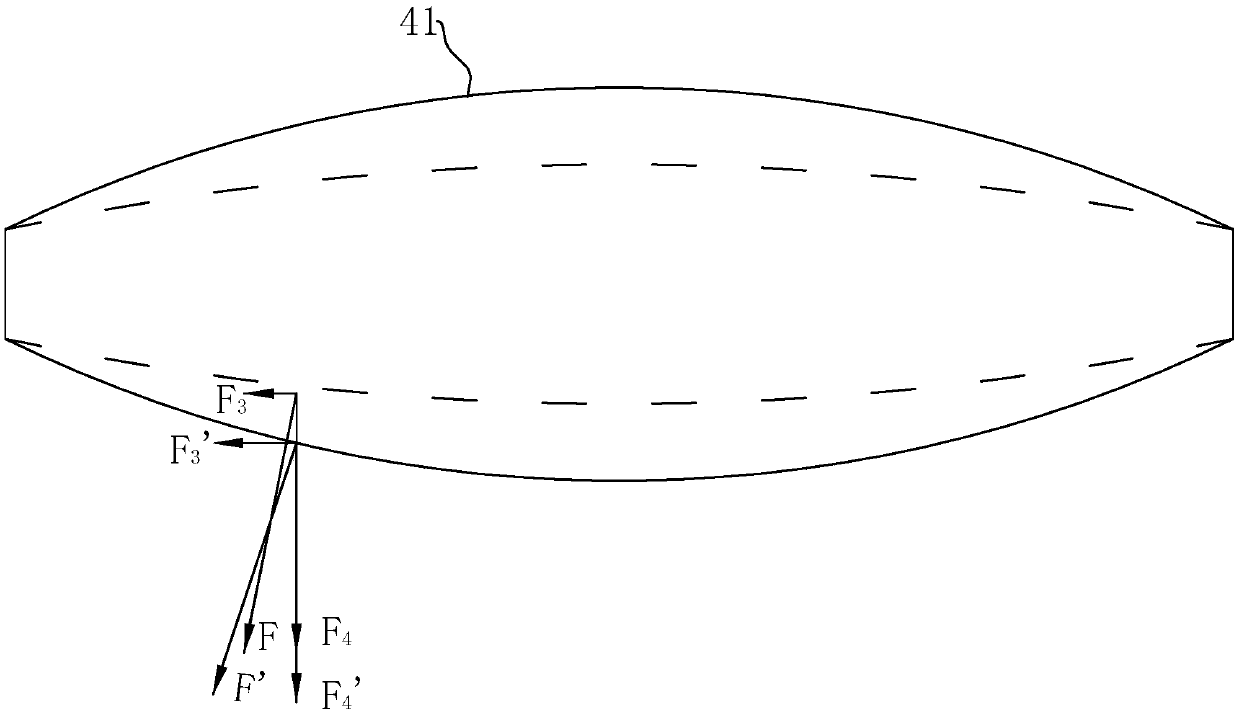

[0039] Embodiment: a kind of discharging roller of spreading machine, as figure 1 As shown, the stretching machine includes a workbench 1 and a moving frame 2 that can move horizontally and linearly on the workbench 1. The moving frame 2 is divided into a feed end and a discharge end. The feed end is located at figure 1 One end in the direction indicated by the middle arrow V, the discharge end is located at the other end of the moving frame 2 opposite to the feed end, and the moving frame 2 is rotatably connected to a pair of main output rollers 3 arranged side by side close together at the discharge end for Output the cloth to the top of the workbench 1 smoothly; the cloth roll enters the moving frame 2 from the feeding end, passes through the discharging end, and then goes around the main output roller 3, and the moving frame 2 moves along the figure 1 When moving in the direction indicated by the middle arrow V, the cloth passes out from under the main output roller 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com