A samarium-containing cerium-based polishing powder and its preparation process

A preparation process and polishing powder technology, which is applied in the direction of polishing compositions containing abrasives, other chemical processes, chemical instruments and methods, etc., can solve the problems of resource backlog, low value of samarium element, and inability to form market sales, etc., to achieve pollution Small, uniform crystal grains, easy for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

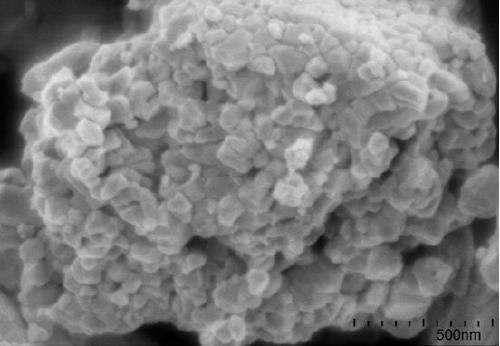

Embodiment 1

[0027] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=0.0086,Nd 2 o 3 / TREO=0.0021, the balance is CeO 2 / TREO=0.559, the molar concentration of the salt solution is 1.16mol / L. Add 1m into the reaction vessel 3 water, and add 100L rare earth salt solution, the diluted salt solution is used as the reaction bottom liquid, so that the molar concentration of the rare earth salt solution as the bottom liquid is 0.12mol / l; prepare the ammonium bicarbonate solution, and adjust the bicarbonate concentration to be the rare earth salt solution 3.5 times the molar concentration. Raise the temperature of the liquid in the reaction vessel to 40°C, and at the same time add the rare earth salt solution and the precipitating agent into the reaction vessel, the flow ratio of the rare earth salt solution and the precipitating agent is 1:1. After adding 400L of the rare earth salt solution, sto...

Embodiment 2

[0029] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=0.00014,Nd 2 o 3 / TREO=0.0021, the balance is CeO 2 / TREO=0.577, the molar concentration of the salt solution is 1.74mol / L. Add 1m into the reaction vessel 3 water, and add 100L rare earth salt solution, the diluted salt solution is used as the reaction bottom liquid, so that the molar concentration of the rare earth salt solution as the bottom liquid is 0.15mol / l; prepare the ammonium bicarbonate solution, and adjust the bicarbonate concentration to be the rare earth salt solution 3.16 times the molar concentration. Raise the temperature of the liquid in the reaction vessel to 45°C, and at the same time add the rare earth salt solution and the precipitating agent into the reaction vessel, the flow ratio of the rare earth salt solution and the precipitating agent is 1:2. After adding 400L of the rare earth salt solution, s...

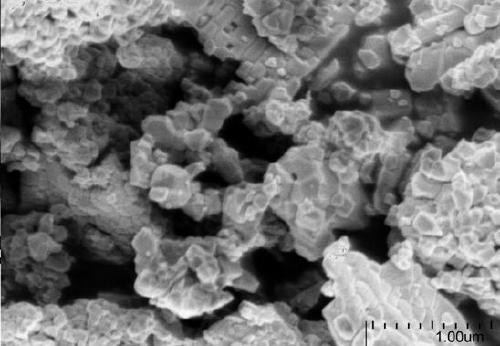

Embodiment 3

[0031] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=0.029,Nd 2 o 3 / TREO=0.00743, the balance is CeO 2 / TREO=0.508, the molar concentration of the salt solution is 1.25mol / L. Add 1m into the reaction vessel 3 water, and add 100L rare earth salt solution, the diluted salt solution is used as the reaction bottom liquid, so that the molar concentration of the rare earth salt solution as the bottom liquid is 0.17mol / l; prepare the ammonium bicarbonate solution, and adjust the bicarbonate concentration to be the rare earth salt solution 3.0 times the molar concentration. Raise the temperature of the liquid in the reaction vessel to 45°C, and at the same time add the rare earth salt solution and the precipitating agent into the reaction vessel, the flow ratio of the rare earth salt solution and the precipitating agent is 1:1. Stop adding the rare earth salt solution after adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com