Coiled tubing directional tool control system and method for micro wellbore

A control system and micro-hole technology, applied in the automatic control system of drilling, directional drilling, earthwork drilling and mining, etc., can solve the problems of occupying the rock-carrying mud channel, unreliable locking mechanism, and unsuitable directional tools, etc., to achieve The effect of saving design space, convenient control, and saving operation auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

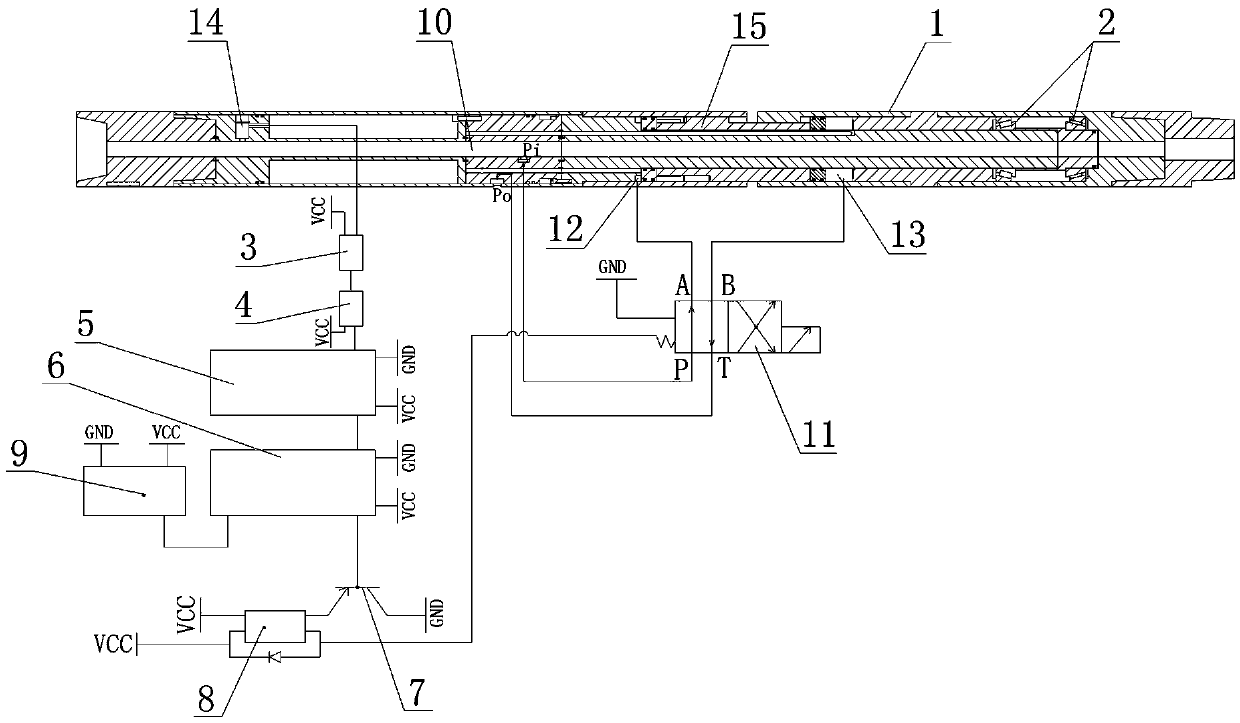

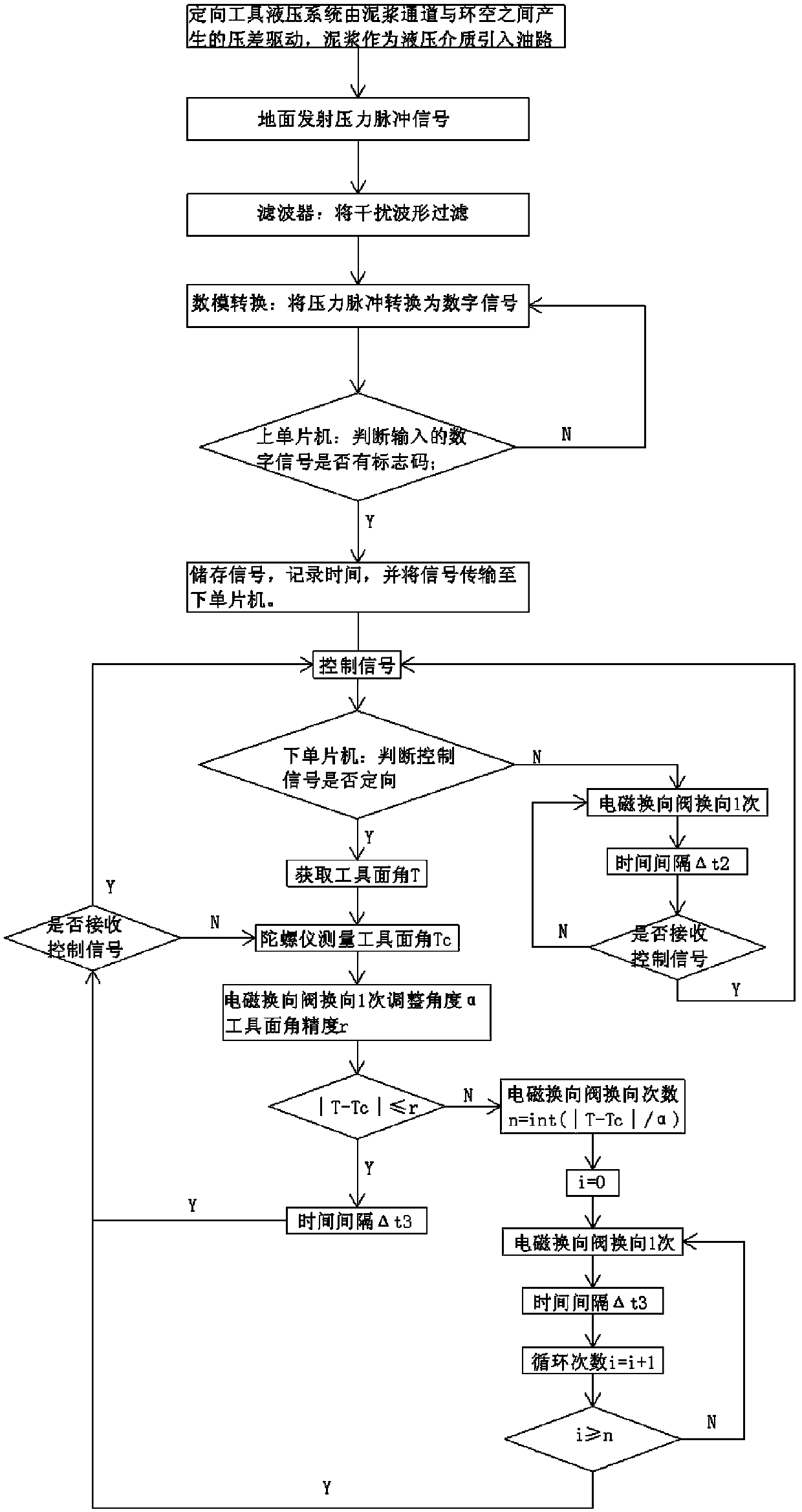

[0023] Such as figure 2 As shown in Fig. 1, a control system for the directional tool of the coiled tubing in micro wellbore, the rotating outer cylinder 1 of the directional tool is installed on the main body through the tapered roller bearing 2, and the tapered roller bearing at the left end can offset the commutation or the continuous down The tapered roller bearing at the right end can offset the axial load generated during drilling, and can transmit the counter torque generated by the bottom power drilling tool to the angle adjustment cylinder 15 at the same time. The control system includes a hydraulic circuit and a control circuit, and the control circuit includes a pressure sensor 3, a filter 4, an upper single-chip microcomputer 5, a lower single-chip microcomputer 6, a triode 7 and a relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com