Multifunctional epoxy coating prestressed tendon production line

An epoxy coating and prestressing tendon technology, which is applied in the field of prestressing tendon production lines, can solve the problems of the production line being unable to work for a long time and the length of the center wire, so as to achieve the effects of convenient and quick replacement, reduced use space, and thorough cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

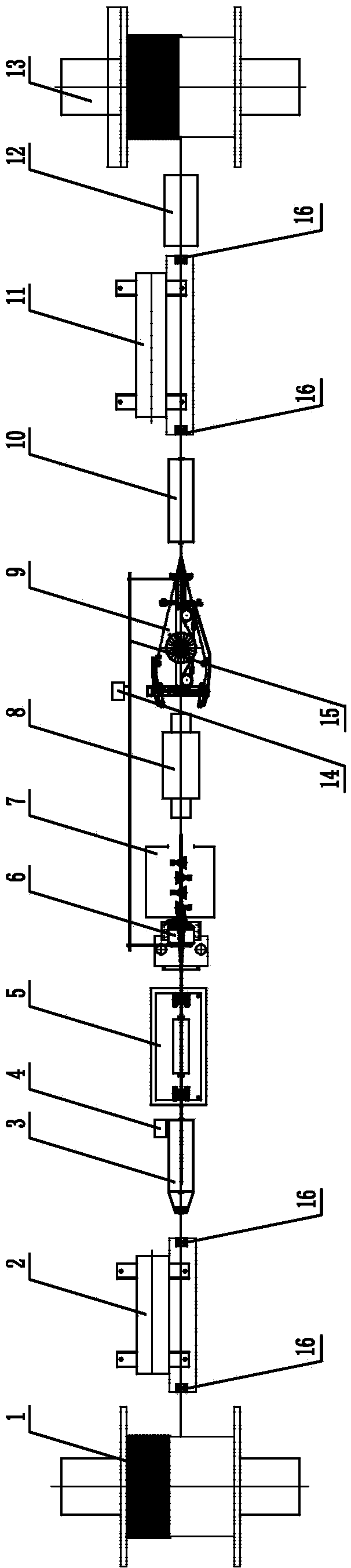

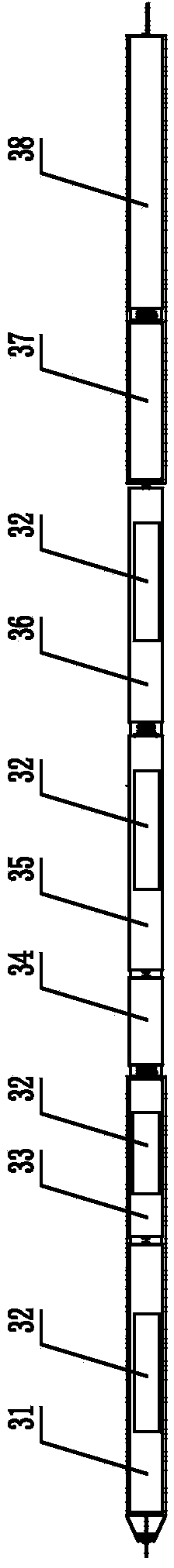

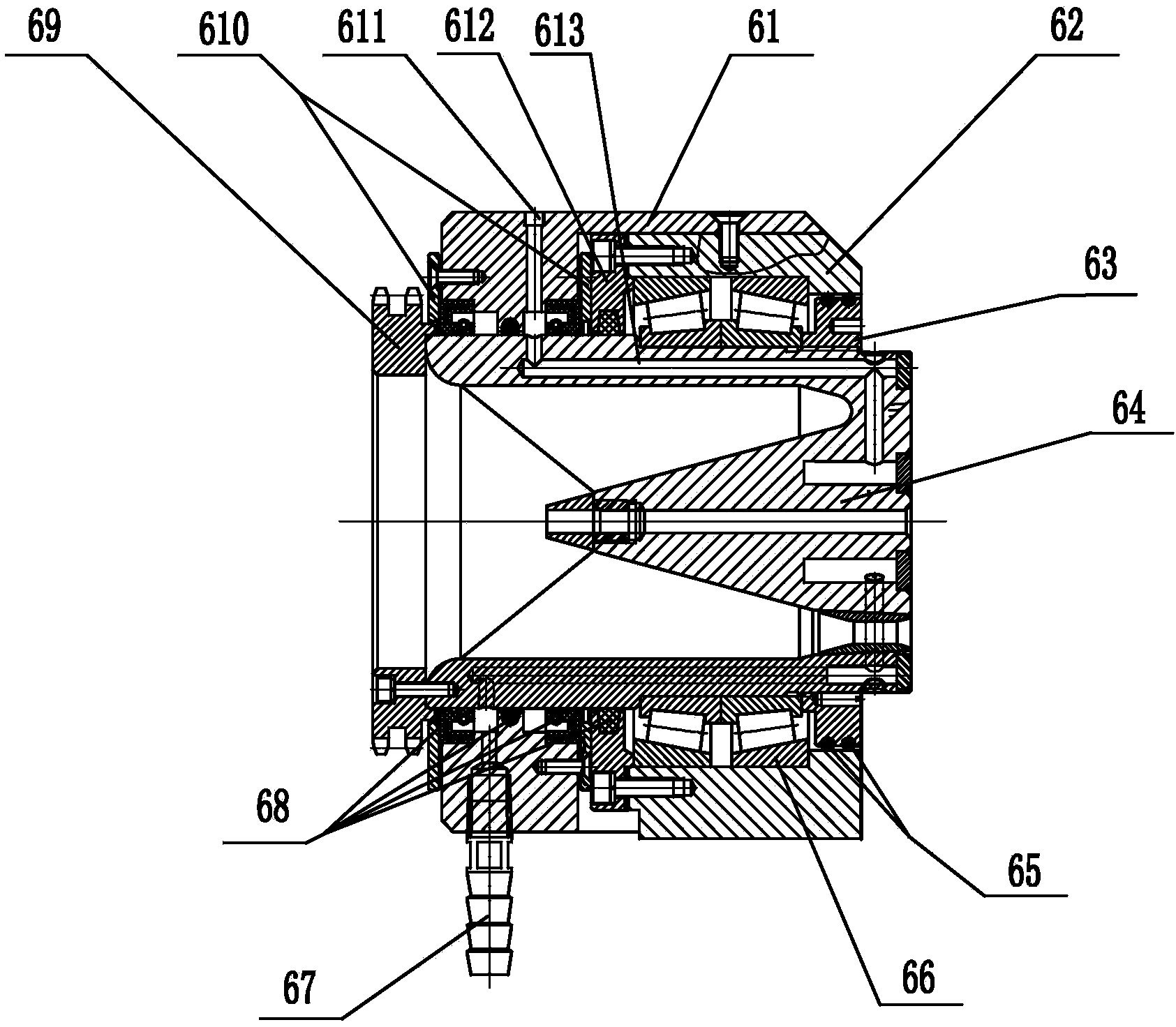

[0051] Embodiment 1: A multifunctional epoxy-coated prestressed tendon production line, including a pay-off machine 1, a tractor I 2, a cleaning tank group 3, an intermediate frequency heating furnace 5, a wire separator 6, an electrostatic spraying box 7, Device A8, central wire tensioning mechanism 9, cooling tank 10, traction machine II 11 and wire take-up machine 13, the multifunctional epoxy coating prestressed tendon production line also includes an incubator, a semi-finished product cooling tank, a driving motor 14 and a The long transmission shaft 15 connected to the drive motor, the long transmission shaft is respectively connected with the wire dividing disc 6 and the central wire tensioning mechanism 9, and the described device A8 is one of an incubator and a cooling tank for semi-finished products, i.e. an incubator The semi-finished cooling tank is not fixed (other equipment in the production line is fixed at a certain position), and the corresponding equipment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com