A self-priming centrifugal pump system driven by an air compressor

A technology of air compressors and centrifugal pumps, which is applied in the direction of driving pumps, machines/engines, and components of pumping devices for elastic fluids. It can solve the problems of complex operation, unstable operation, and complex structure of the whole machine, and achieve Reduce space volume, improve self-priming efficiency, and overcome partial reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

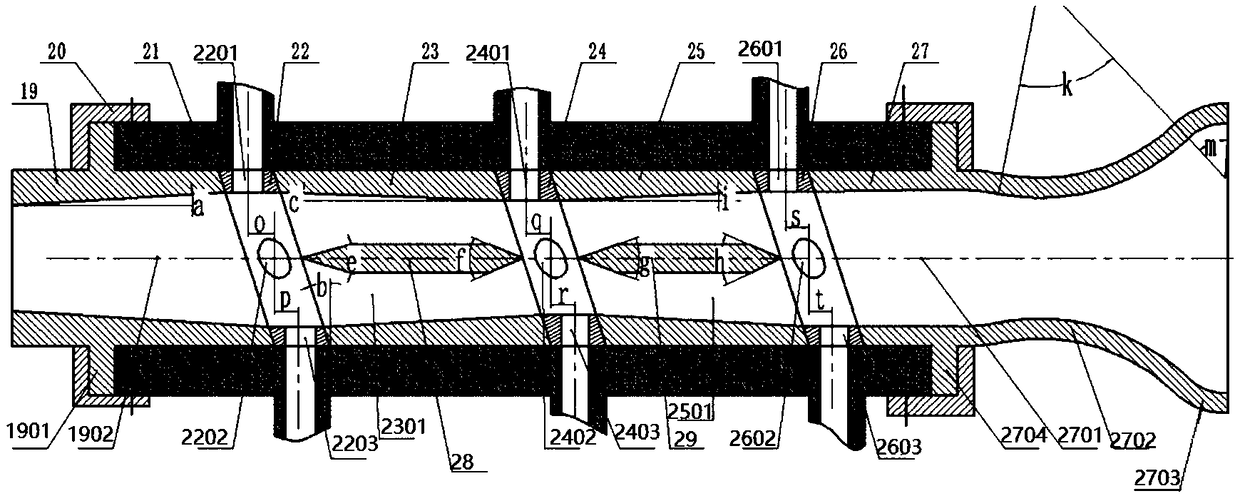

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

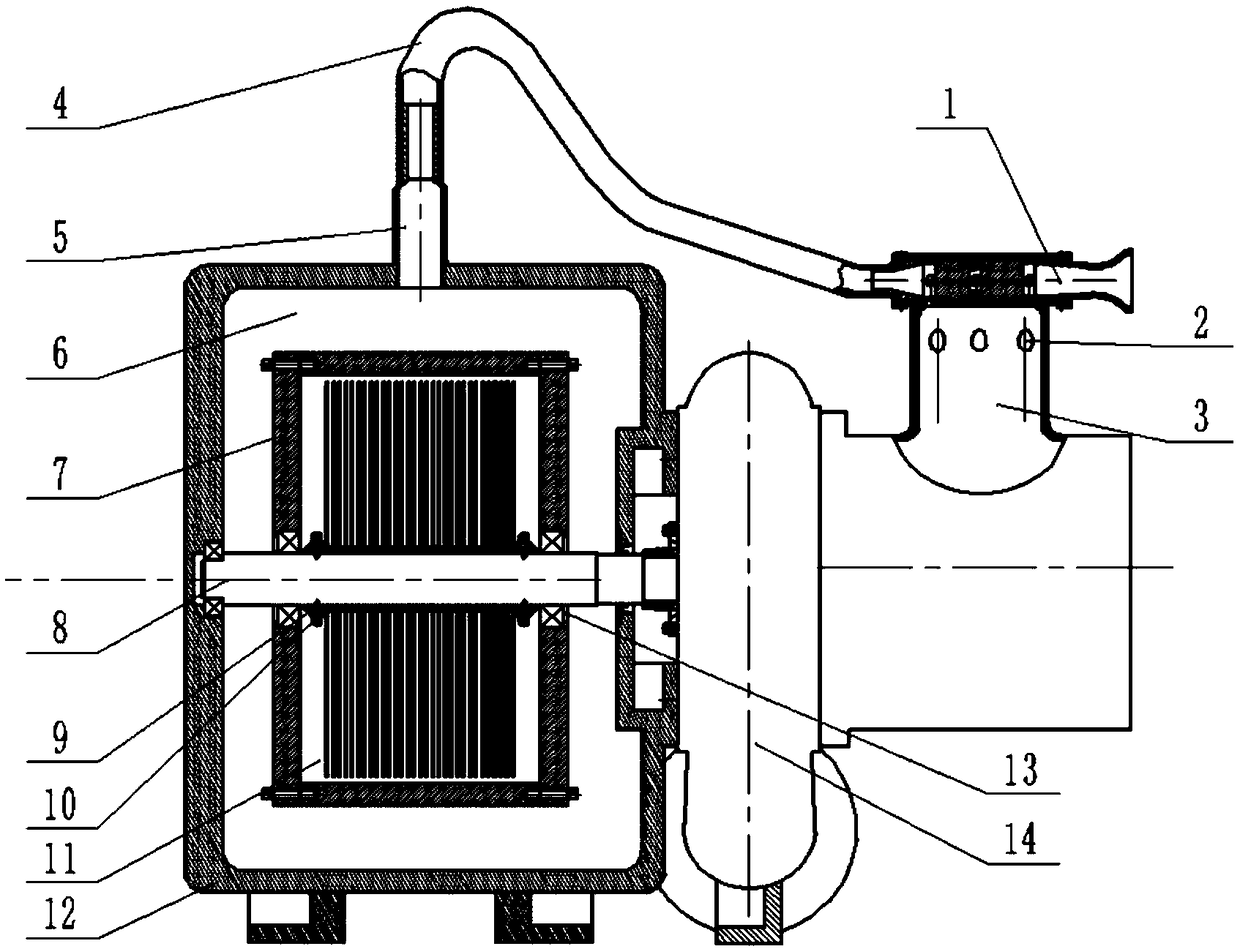

[0043] Such as figure 1 As shown, a self-priming centrifugal pump system driven by an air compressor according to the present invention includes a self-priming exhaust system 1, a pump body 14, an air suction chamber 3 and a driving device, and the driving device includes an air compressor, an external The vortex chamber 12, the inner vortex chamber 7, the base 15 and the thin plate group, the outer vortex chamber 12 and the inner vortex chamber 7 are hollow cylinders made of HT200 material, and the outer vortex chamber 6 is 120 mm wide and 40 mm thick. The diameter of the vortex chamber 11 is 240mm, and the thickness is 30mm.

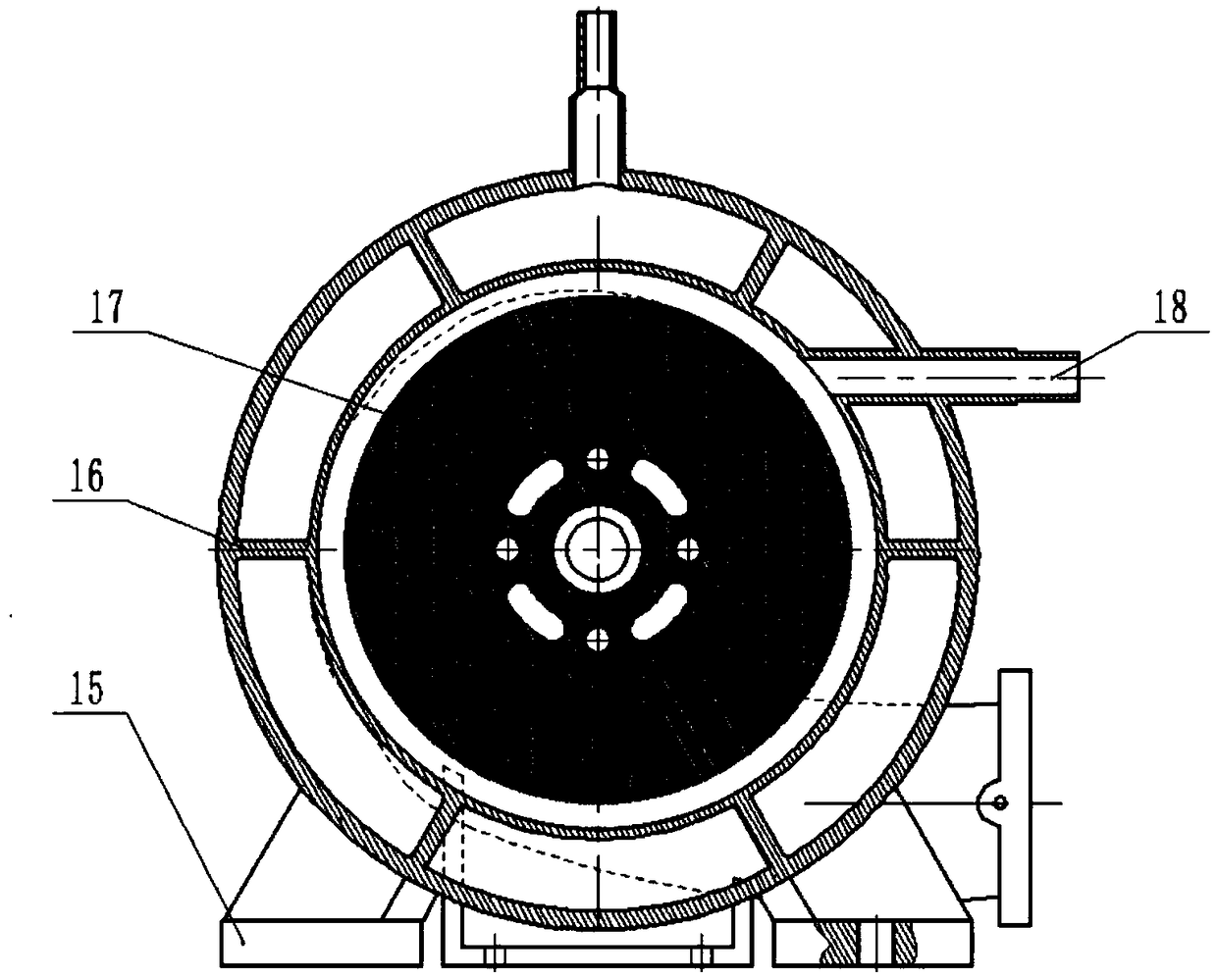

[0044] Such as figure 2 As shown, the inner vortex chamber 7 is located in the outer vortex chamber 12, and six supporting ribs 16 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com