Gear case

A gearbox and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of low bearing capacity, high noise, easy oil leakage, etc., to reduce the probability of leakage , low noise and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

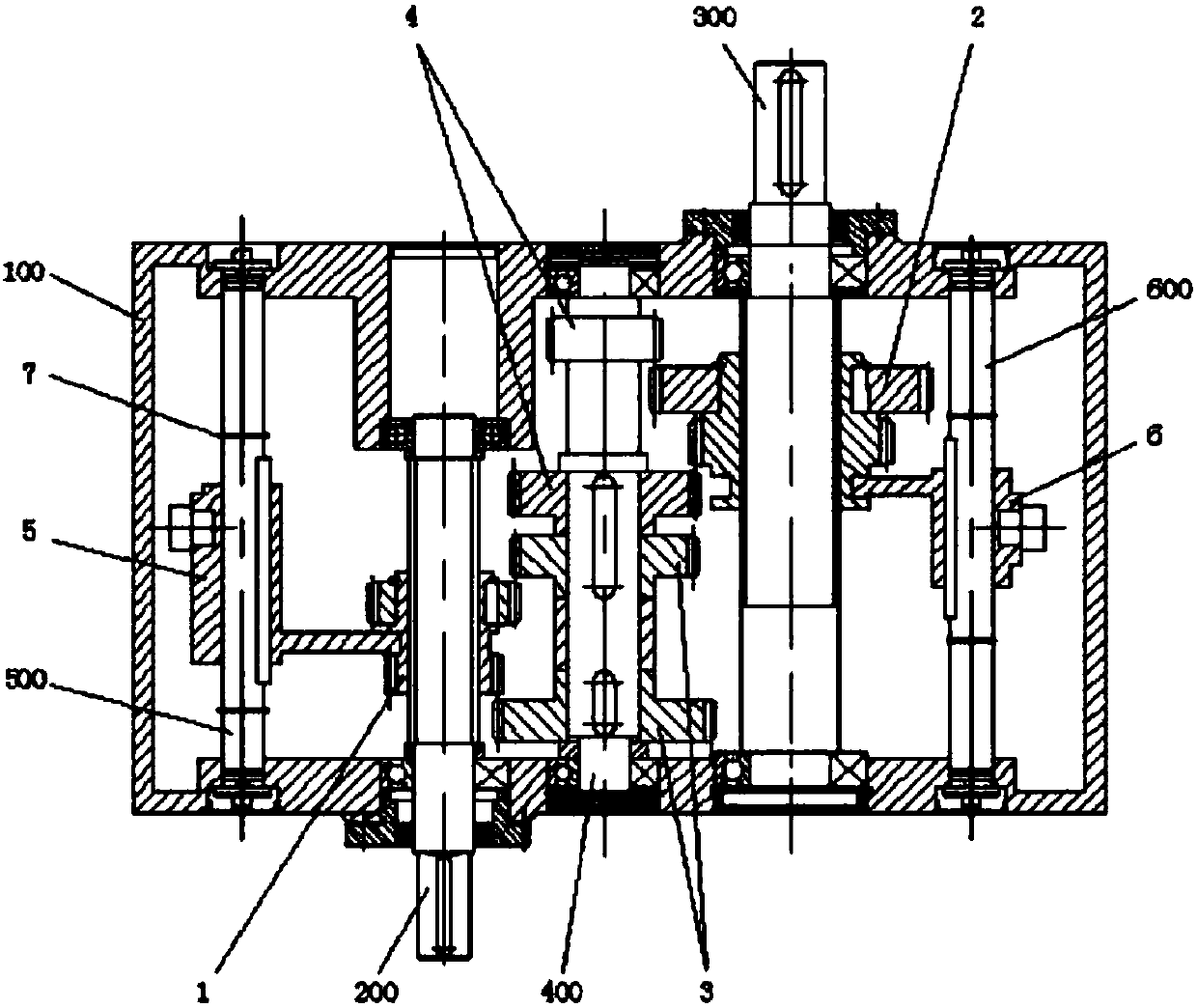

[0013] See figure 1 , the present invention has a box body 100, an input shaft 200 and an output shaft 300; the box body 100 is an integral part casted by HT250 material resin sand casting process, and the input shaft 200 is axially slid to be provided with an input duplex gear 1, The output shaft 300 is axially slid to be provided with the output duplex gear 2, and the transition shaft 400 is provided between the input shaft 200 and the output shaft 300, and the transition shaft 400 is provided with the first duplex gear 3 and the second duplex gear 4, Each of the gears is a shifting spur gear with a split structure, and the tooth profile of each gear’s shifting surface is rounded; the box body 100 is provided with an input guide shaft 500 parallel to the input shaft 200 and an output guide shaft. shaft 600, the input guide shaft 500 is axially slid to be provided with an input shift fork 5, and the output guide shaft 600 is axially slid to be provided with an output shift fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com