Self-adaption pipeline crawling device and pipeline weld seam detecting method

A pipeline crawler, weld detection technology, applied in the direction of pipes/pipe joints/pipe fittings, instruments, pipe components, etc., can solve the problems of low detection efficiency, poor pipe adhesion ability, poor accommodation ability, etc., to achieve high efficiency, structural Simple, reliable detection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

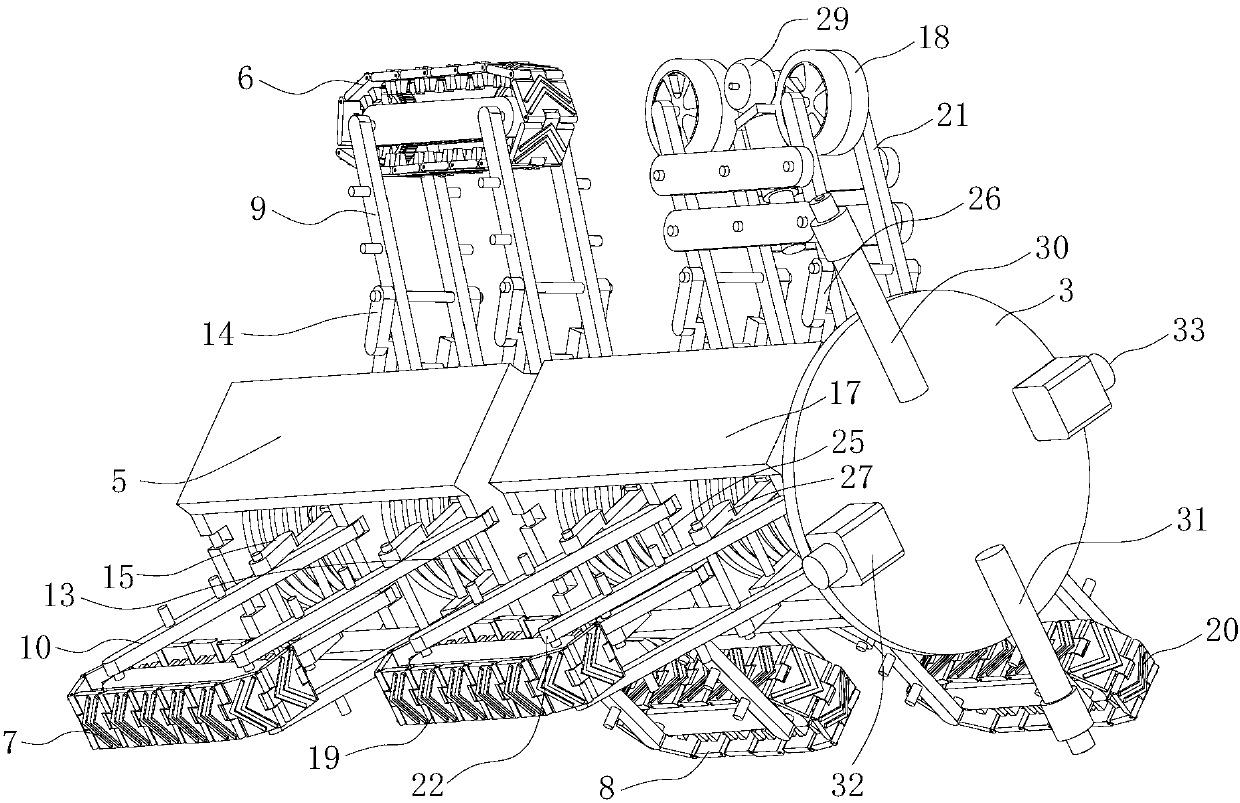

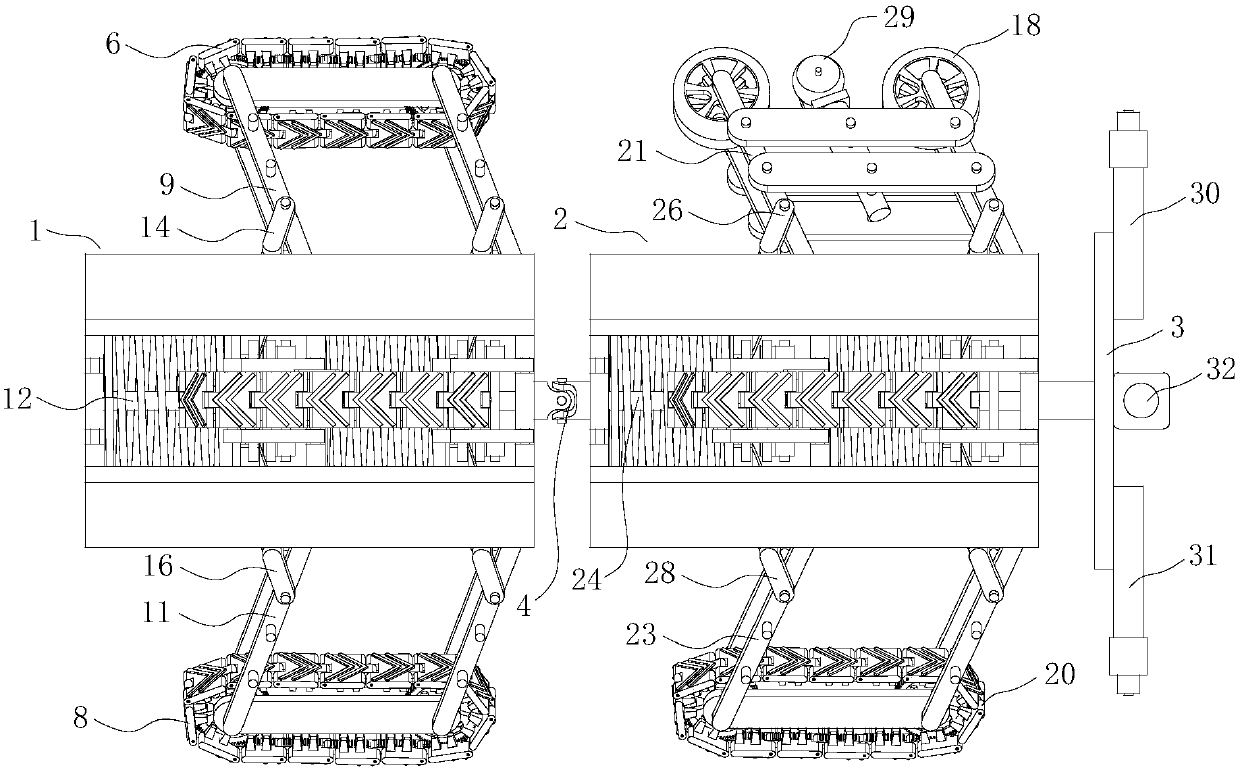

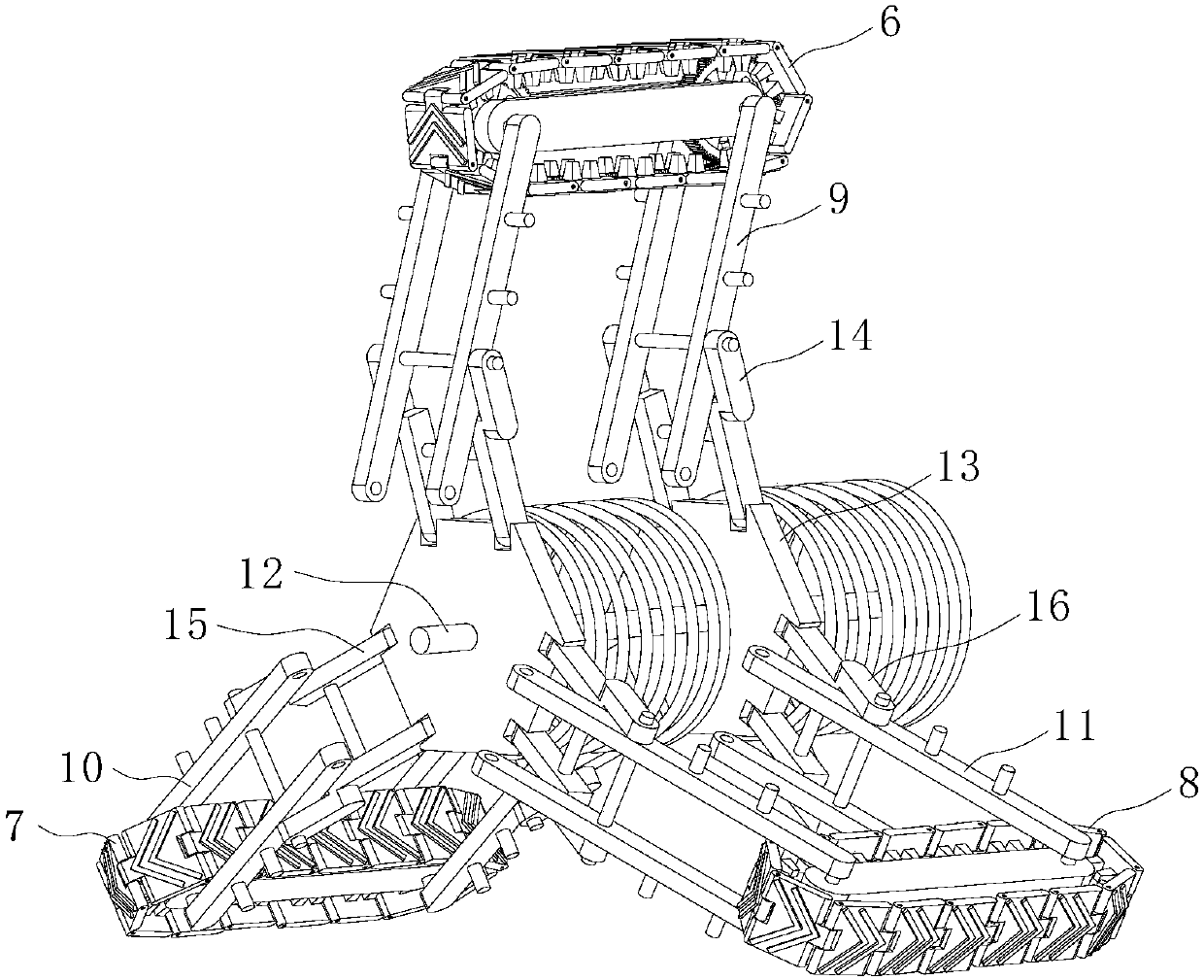

[0039] Such as figure 1 with figure 2 As shown, the present embodiment provides an adaptive pipeline crawler, which includes a front body 1, a rear body 2 and a platform 3, and the front body 1 and the rear body 2 are connected by a coupling 4 is connected, and the coupling 4 is preferably a flexible coupling, and the platform 3 is connected with the rear body 2.

[0040] The front body 1 includes a first casing 5, a first track wheel 6, a second track wheel 7, a third track wheel 8, a first parallelogram mechanism 9, a second parallelogram mechanism 10 and a third parallelogram mechanism 11. The size and structure of the first track wheel 6, the second track wheel 7 and the third track wheel 8 are the same, with built-in independent motors, and all of them are driving wheels. The three track wheels are evenly distributed around the first housing 5, That is, the angle between any two track wheels is 120 degrees; the two ends of the first parallelogram mechanism 9 are respec...

Embodiment 2

[0058] The main features of this embodiment are: the track wheels of the front car body can also be four or more, taking four as an example, the angle between any two track wheels is 90 degrees; The track wheels of the body can also be three or more. Taking three as an example, the angle between any two track wheels is 90 degrees, and the angle between the guide wheel and two adjacent track wheels is 90 degrees. . All the other are with embodiment 1.

Embodiment 3

[0060] The main features of this embodiment are: the number of ultrasonic sensors and cameras on the pan / tilt can be three or more, taking three as an example, the angle between the ultrasonic sensor and two adjacent cameras is 60 degrees . All the other are with embodiment 1.

[0061] In summary, the crawler of the present invention is provided with a front body, a rear body and a cloud platform, and a weld detection device is respectively arranged on the rear body and the platform, and the weld detection device of the rear body can crawl Send and receive detection signals during the forward process of the sensor to detect whether there is a weld. The weld detection device on the pan / tilt can reach the position of the weld when there is a weld to obtain weld information and further detect whether the weld information is In the presence of other damage conditions (such as cracks, corrosion, etc.), it can realize the comprehensive inspection of pipeline welds. It has a simple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com