High and low voltage electric porcelain arrester

A lightning arrester, high-voltage and low-voltage technology, applied in the field of lightning arresters, can solve the problems of high failure rate of catenary lightning strikes, fatal injuries to trains and personnel, and inability to realize large-area lightning protection, etc., to achieve good lightning protection effect, simple installation hoop structure, and convenient assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

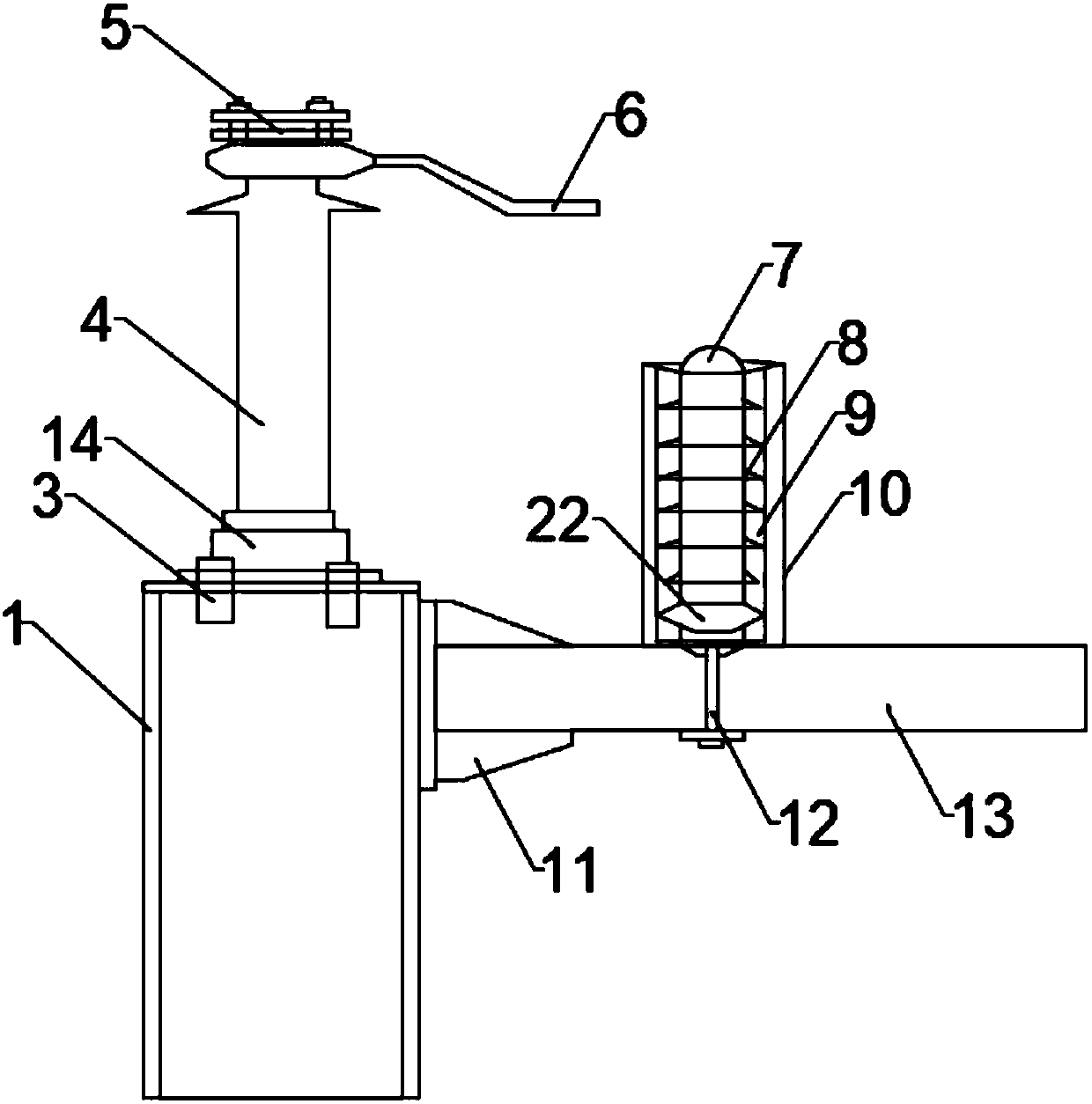

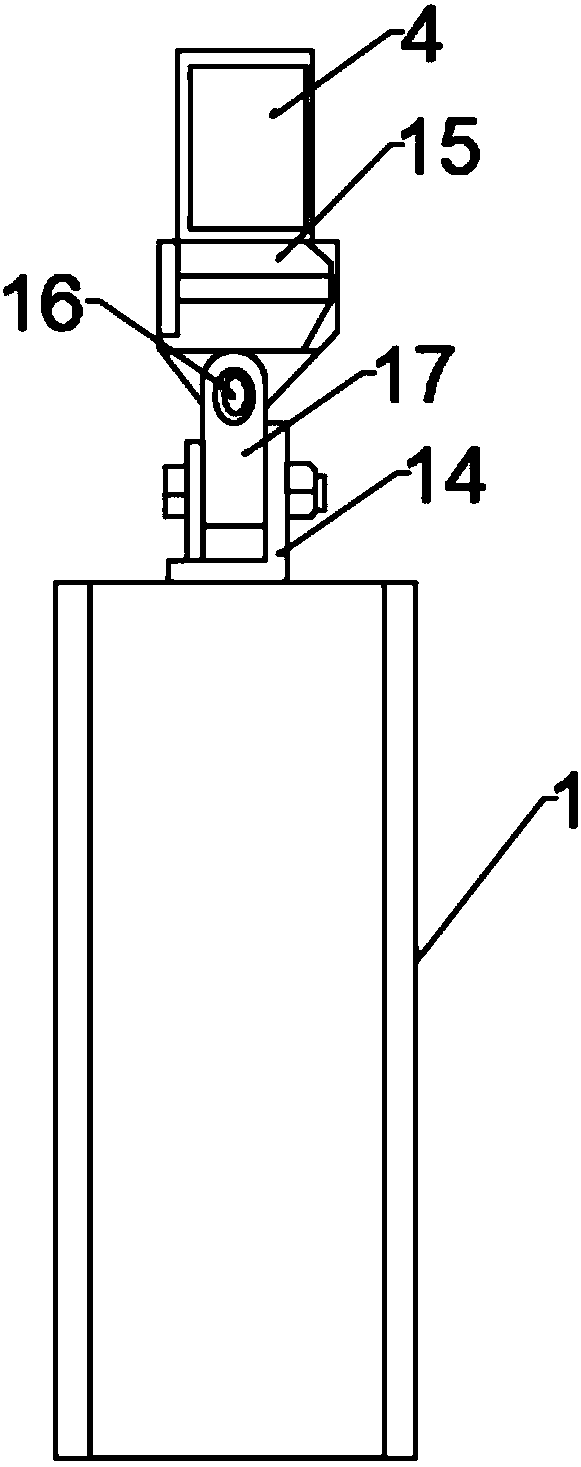

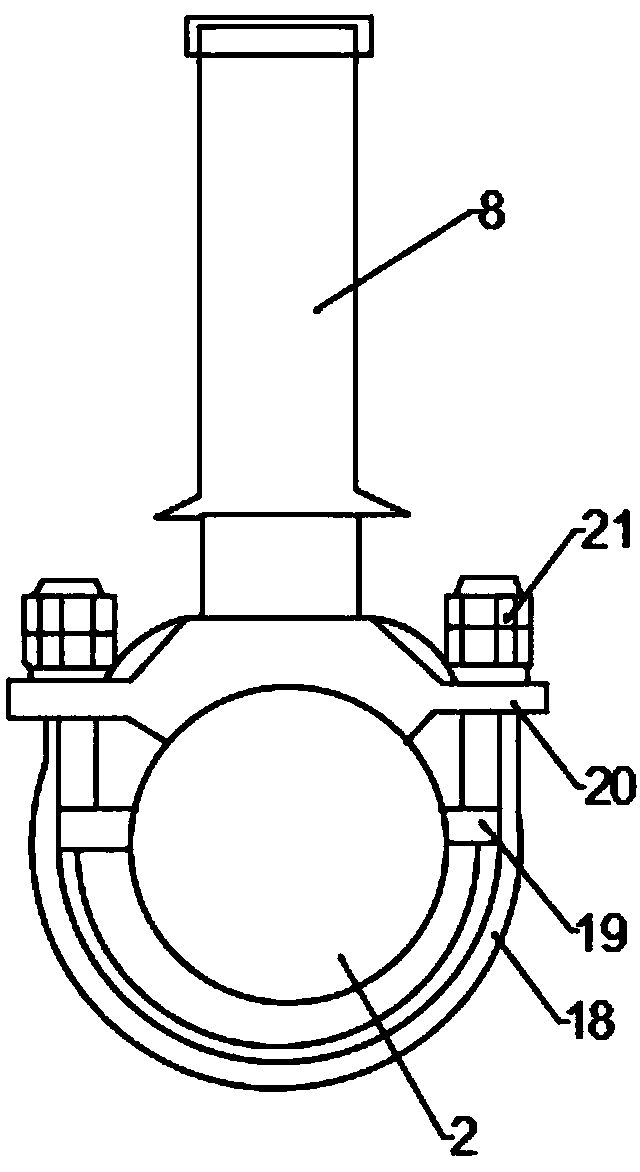

[0025] Such as figure 1 with image 3 As shown, the present invention provides a high and low voltage electric porcelain lightning arrester, comprising a lightning arrester pillar 1 and a pillar insulator 4, the upper surface of the lightning arrester pillar 1 is fixedly installed with a pillar insulator 4 through an adjusting bolt 3, and the upper end of the pillar insulator 4 is set There is a JQ line interface 5, the right end of the JQ line interface 5 is provided with an electrode rod 6, and the right side of the arrester pillar 1 is also connected to the cantilever beam 13 through a fixed bracket 11, and the fixed bracket 11 is connected to the arrester pillar 1 Fixed connection, the upper surface of the cantilever beam 13 is provided with a lightning arrester body 8, the lower end of the lightning arrester body 8 is embedded on the inner wall of the cantilever beam 13 through the lightning arrester installation device 12, and the upper end of the lightning arrester body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com