High-precision comprehensive production numerical control machine tool with 3D printing

A 3D printer and CNC machine tool technology, applied in the field of CNC machine tools, can solve the problems of unqualified processing size, increase production cost, and unsatisfactory production and processing, and achieve the effect of accurate processing size, prolonging service life, and increasing functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

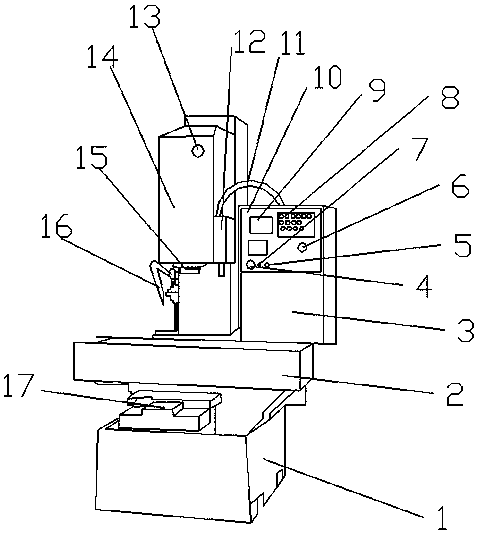

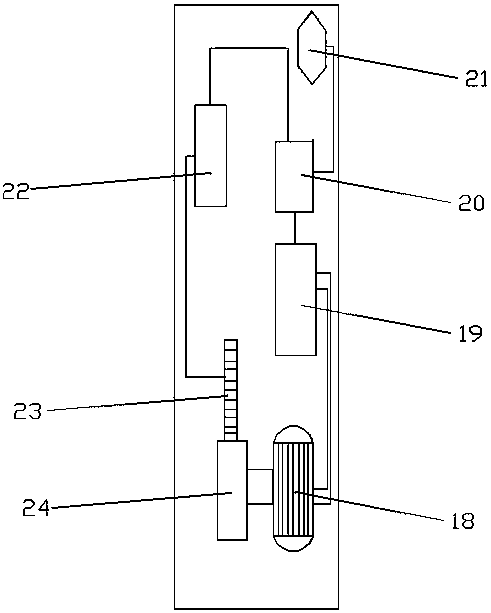

[0013] see Figure 1-2 , a high-precision comprehensive production CNC machine tool with 3D printing, including a waste box 1, a workbench 2, a 3D hot melt feeding device 3, a control box 10, a 3D printer head 12, a CNC machine tool main body 14 and a controller 18, A moving block 17 is installed above the waste box 1, a worktable 2 is installed above the moving block 17, a 3D hot melt feeding device 3 and a control box 10 are installed above the worktable 2, and a stop button 4 is installed on the surface of the control box 10, A working indicator light 7 is installed on the right side of the stop button 4, and a fault indicator light 5 is installed on the right side of the working indicator light 7, a liquid crystal display screen 9 is installed above the fault indicator light 5, and a function key 8 is installed on the right side of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com