Hot melting material and 3D printed finished product waste recycling and re-machining fusion wire extruding machine

A hot-melt material and melt extrusion technology, applied in the field of increased material manufacturing, can solve the problem of not cooperating with enterprises to recycle waste printed products and scattered filaments, increase the production and use costs of 3D printing, recycling costs and high production costs. , to achieve good market application prospects, broad market application prospects, and reduce production and use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

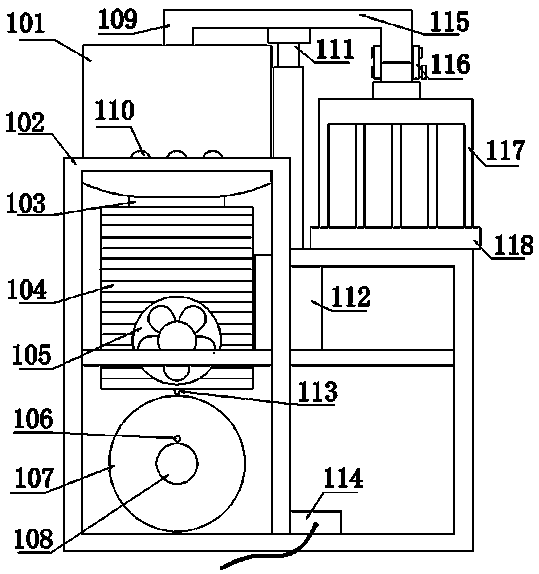

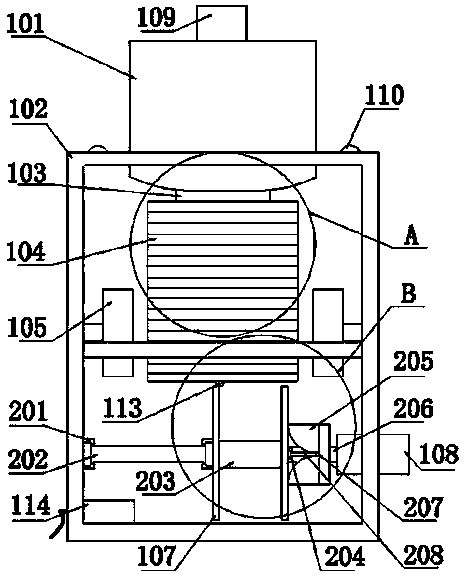

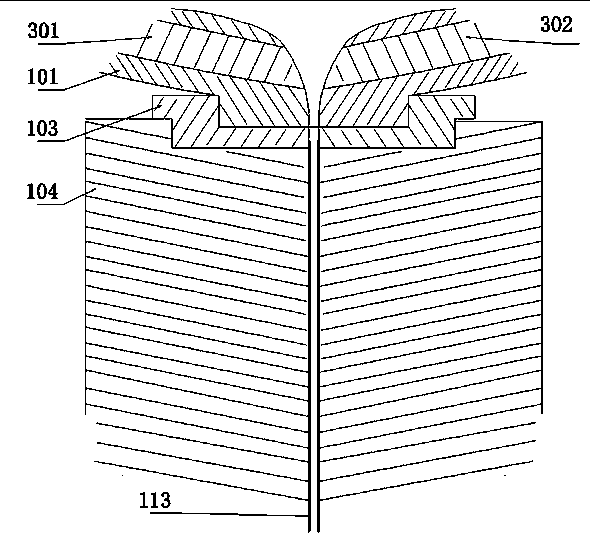

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13As shown, the present invention is a kind of waste recycling and reprocessing melting and extrusion wire rod machine for hot-melt materials and 3D printing products, including a hot-melt extrusion device, a crushing and decomposition device and a base workbench. The hot-melt extrusion device is installed on On the base workbench, it is characterized in that: the hot melt extrusion device is provided with a hot melt cylinder 101, a heat dissipation extrusion member 104, a winding mechanism and an electric push rod 112; the hot melt cylinder 101 is provided with a piston type sealing cover 502, The discharge port 302 and the electric heating part a301, the piston-type sealing cover 502 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com