Road-railway concrete transporting tank truck

A road-rail dual-use and concrete technology, which is applied to rail and road dual-use vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of tank capacity limitation, inability to meet, and increase the cost of winch transportation, and achieve operational flexibility. The effect of good, strong practicability and high road adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will be attached Figure 1~6 The present invention is further described with examples.

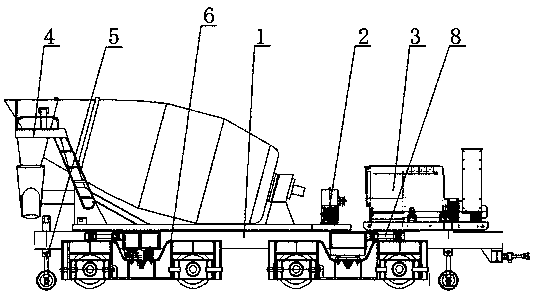

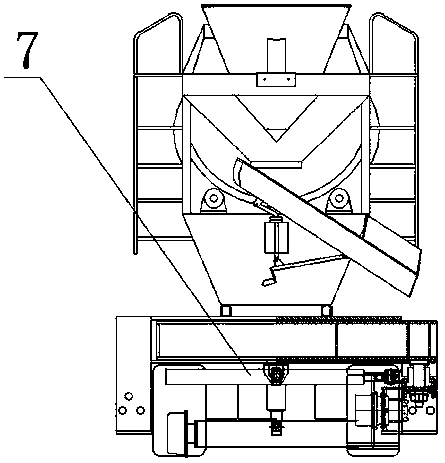

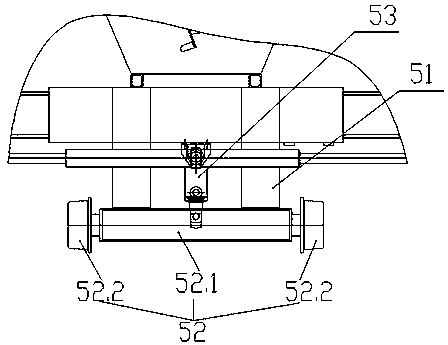

[0037]Concrete delivery tanker for road and rail, including frame 1, hydraulic system 2 for transmitting hydraulic power to various parts in the tanker, diesel power system 3 for providing kinetic energy for hydraulic system 2, concrete mixing tank 4 installed on frame 1, The guide steel wheel device 5 installed at the bottom of the vehicle frame 1 and can extend vertically to cooperate with the rail, the tire running device 6 installed at the bottom of the vehicle frame 1 for driving the tanker on the road, and the horizontally arranged and retractable wheel frame The expansion device 7 and the hydraulic steering device 8 are characterized in that the front and rear ends of the bottom of the vehicle frame 1 are equipped with a guide steel wheel device 5 and a wheel frame expansion device 7, and both ends of the wheel frame expansion device 7 are equipped with winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com