Heat-shrinking-film-protected anchor bolt and anchor bolt protection method

A technology of anchor bolts and heat-shrinkable films, which is applied in the direction of screws, threaded fasteners, and connecting components, can solve the problems of unprotected anchor bolts, time-consuming and labor-intensive protection methods, and difficulty in achieving the purpose of protection. Simple, obvious protective effect, avoiding the effect of external environment erosion and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

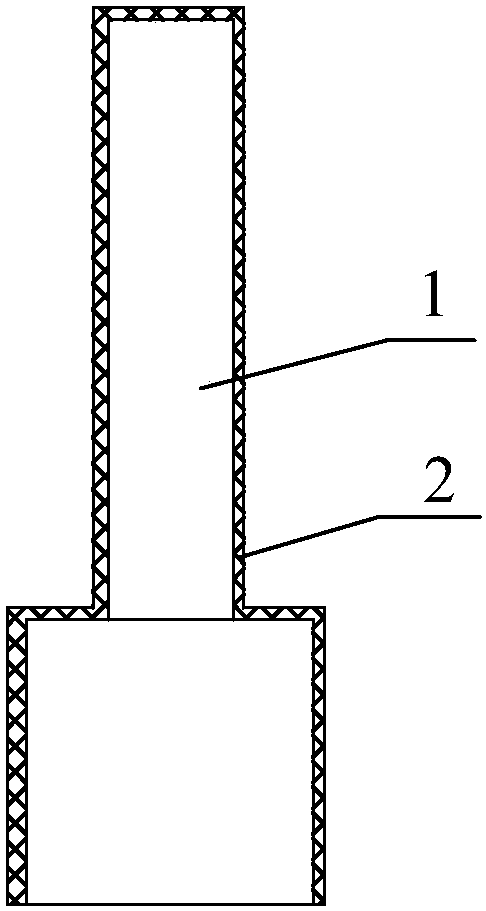

[0012] The heat-shrinkable film-protected anchor bolt provided by the present invention includes an anchor bolt 1 , and the exposed part of the anchor bolt 1 is covered with a heat-shrinkable film layer 2 .

[0013] The heat-shrinkable film layer 2 and the anchor bolt 1 are tightly covered, and the heat-shrinkable film layer 2 and the anchor bolt 1 are directly bonded together by physical means, without adding adhesives and other substances in the middle, avoiding the need for adhesives, etc. The secondary damage of the substance to the anchor bolts. Moreover, the bonding and coating effects are good, there will be no internal air erosion and oxidation of anchor bolts, and it can also avoid external environmental erosion, oxidation and pollution.

[0014] The construction method is as follows: the exposed part of the anchor bolts is covered with a heat-shrinkable film, and then the heat-shrinkable film is heated by hot air until the heat-shrinkable film shrinks and completely ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap