Air conditioner filter cartridge cleaning and drying device

The technology of drying device and filter cartridge is applied in the directions of drying gas arrangement, drying, drying machine, etc., which can solve the problems of long drying time and inability to put into use in time, affecting the air supply volume of air-conditioning units, and splashing sewage on the cleaning site. Achieving no dead corner cleaning, conducive to uniform distribution, and the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

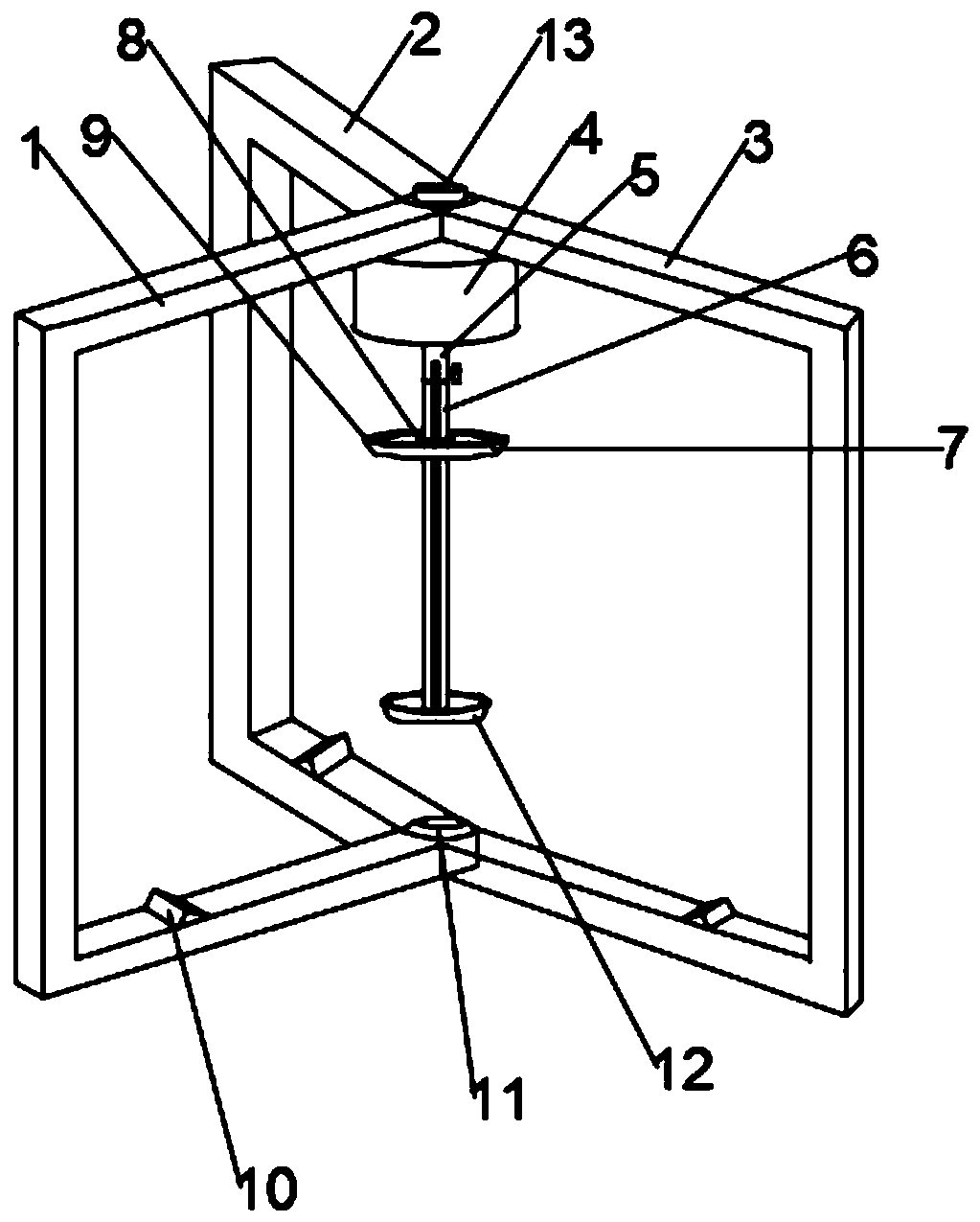

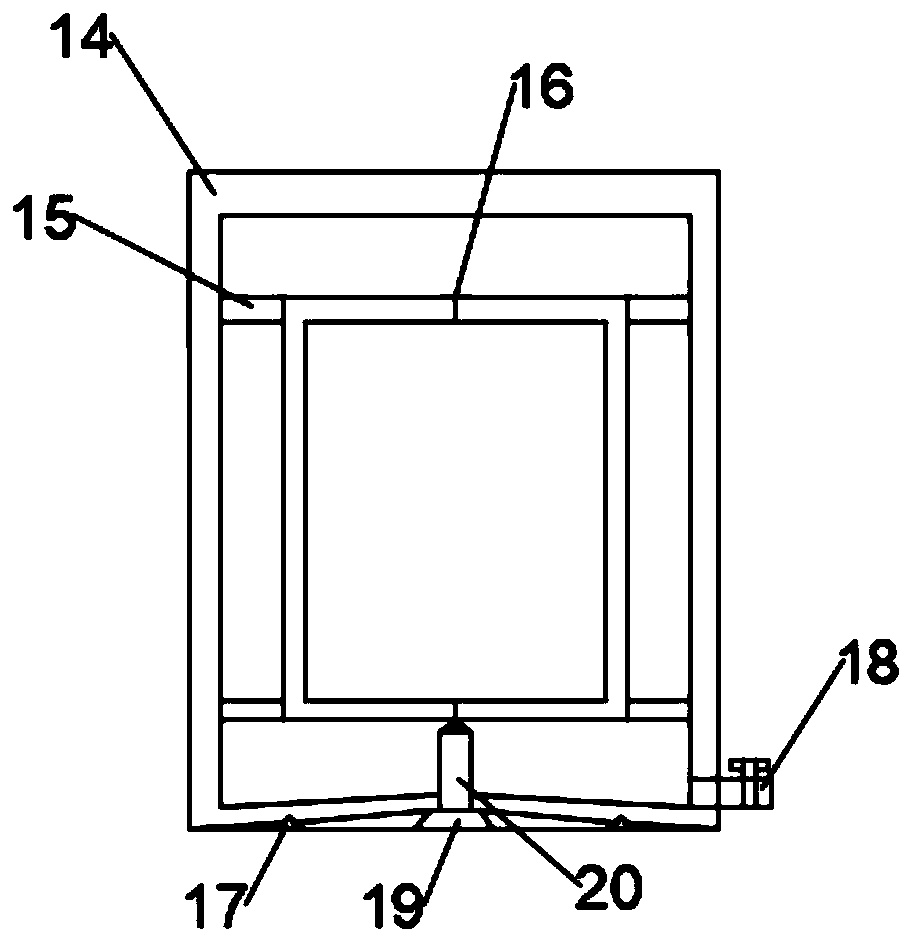

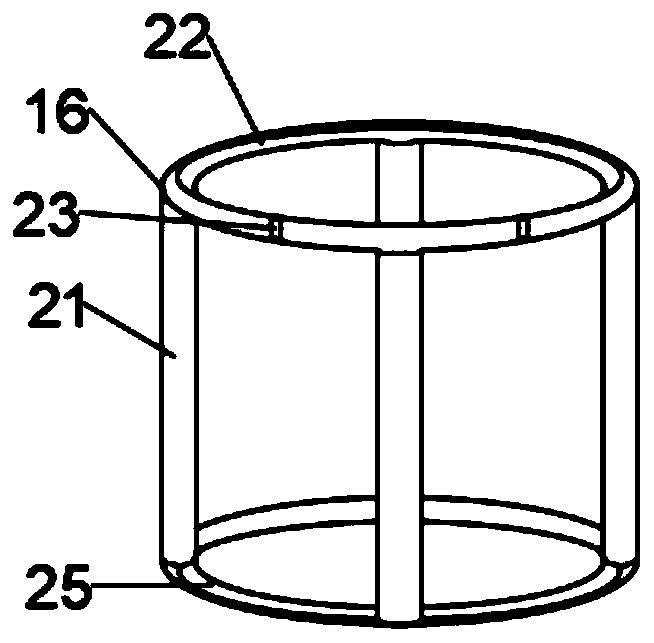

[0023] Such as figure 1 and Figure 5 As shown, the present invention provides an air conditioner filter cartridge cleaning and drying device, comprising a main folding frame 1, a first auxiliary frame 2 and a second auxiliary frame 3, and the main folding frame 1, the first auxiliary frame 2 and the second The top and the bottom of the auxiliary bracket 3 are all hinged together by a bolt shaft 13, a motor 4 is installed on the top of the main folding frame 1, and the motor 4 is connected with a flower shaft 6 through a rotating shaft 5, and a fixed shaft is installed on the top of the flower shaft 6. The pressure plate 7, the outer ring of the constant pressure plate 7 is provided with a rubber outer ring 9, the constant pressure plate 7 is fixed on the flower shaft 6 through the fastening button 8, the bottom of the flower shaft 6 is equipped with a chassis 12, the The bottom frames of the main folding frame 1, the first auxiliary bracket 2 and the second auxiliary bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com