Design method of cold spray nozzle for cold spraying

A design method and cold spraying technology, applied in the direction of calculation, spraying device, spraying device, etc., can solve the problems of long-term modeling and calculation, lack of material specificity of cold nozzles, long design time, etc., and achieve the effect of rapid design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

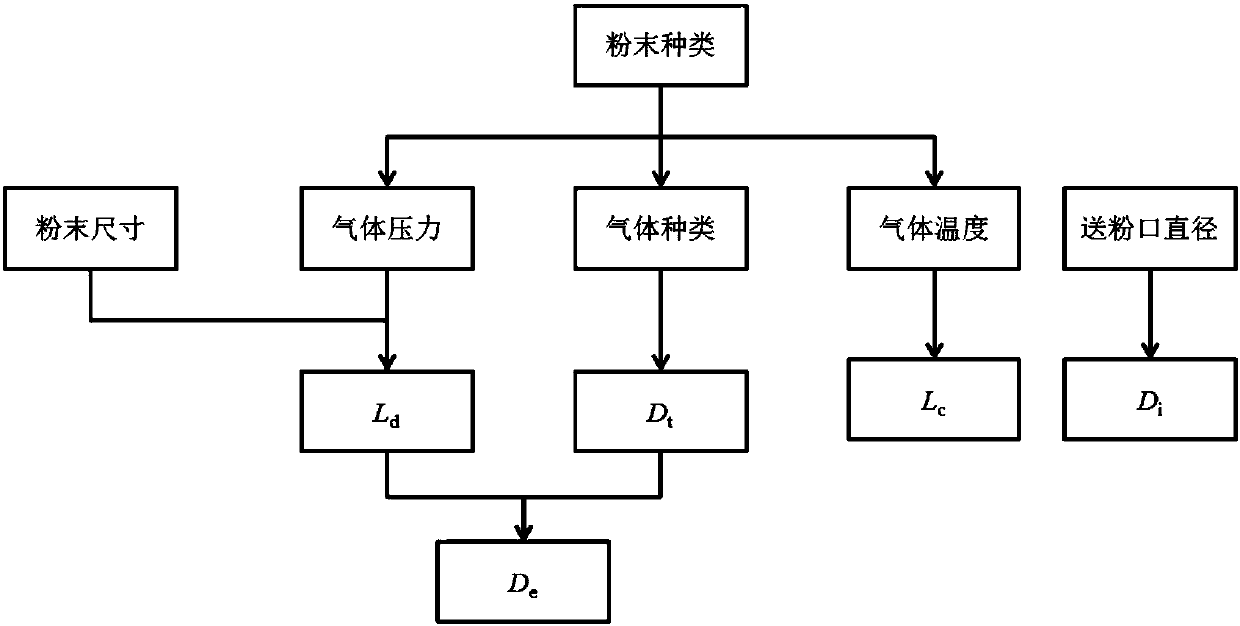

[0042] The cold spray nozzle design method of the present invention, the technical problem to be solved is to set up a series of design principles applicable to the cold spray nozzle, and obtain a set of complete and effective cold nozzle design methods simultaneously, thereby by influencing the nozzle size factors (gas type, The analysis of pressure, powder type, etc.) can quickly design the optimal nozzle.

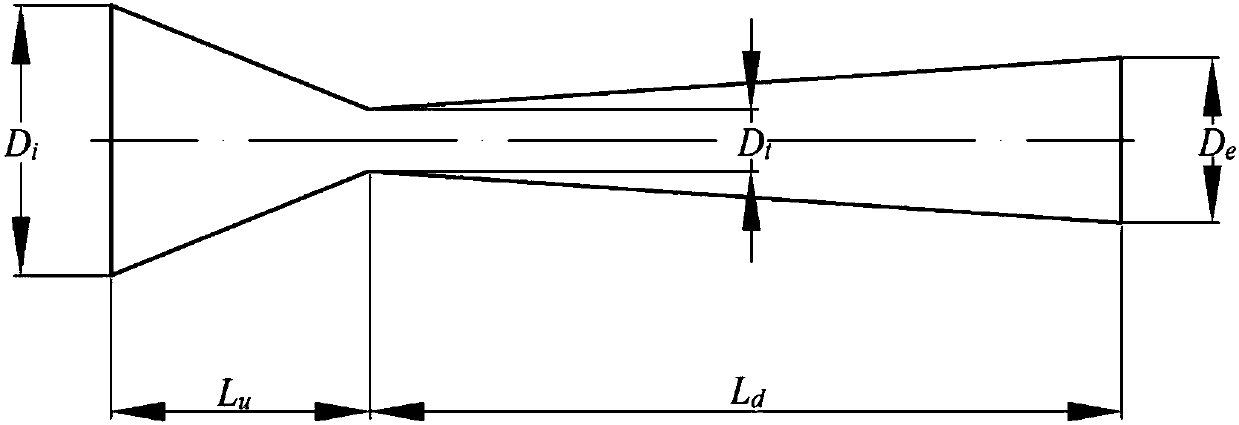

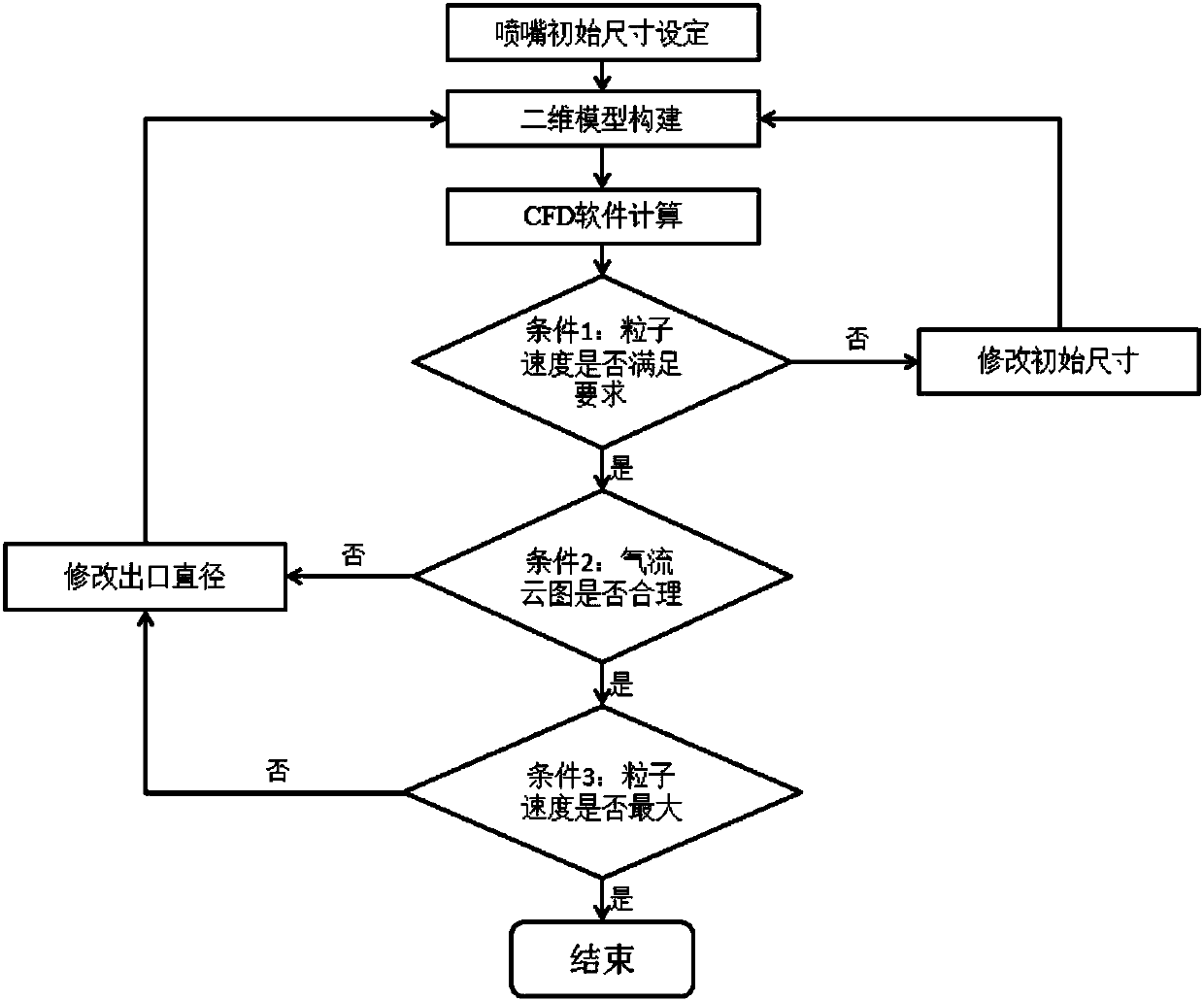

[0043] In order to solve the above technical problems, the present invention proposes a nozzle design method based on the analysis of spraying materials and process parameters combined with CFD. The adopted technical solution is: S1, the original size setting process, based on the analysis and prediction of the key influencing factors on the particle velocity. Nozzle size setting; S2, two-dimensional spraying model construction process, constructing the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com