Ferroelectric resistive random access memory and adjustment and control method of switching ratio of ferroelectric resistive random access memory

A technology of ferrous resistance variable and memory, applied in electrical components and other directions, can solve problems such as unfavorable practical application, complex device preparation process, misoperation, etc., and achieve the effect that is beneficial to practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

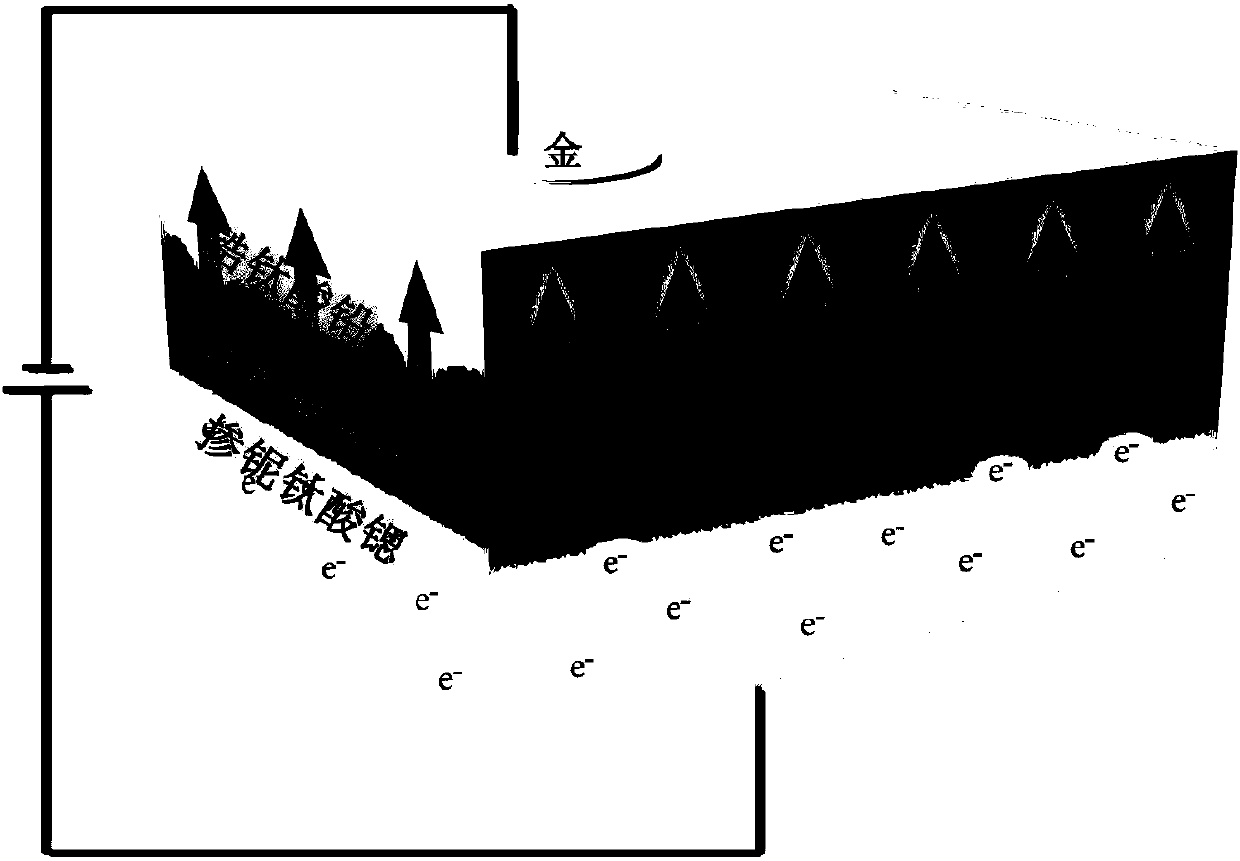

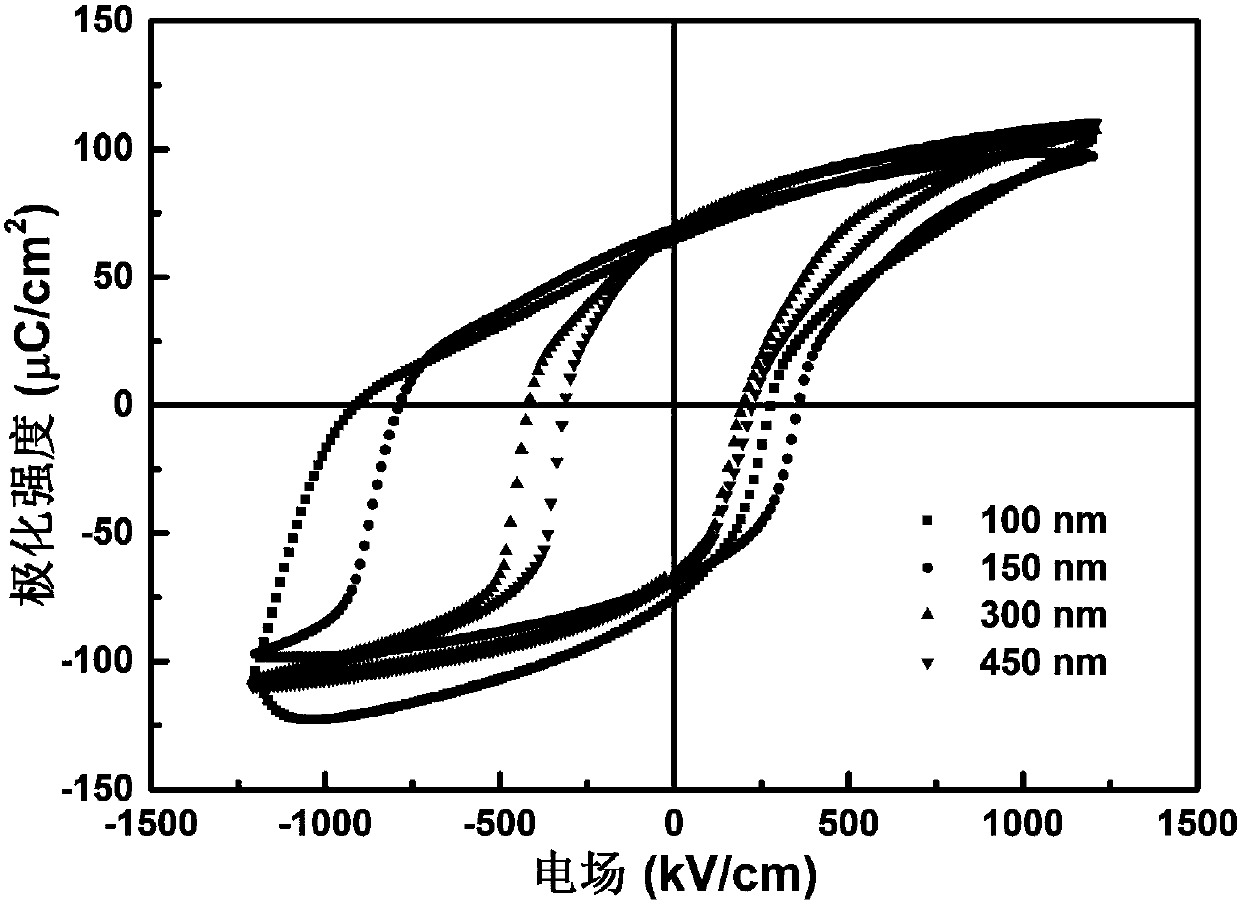

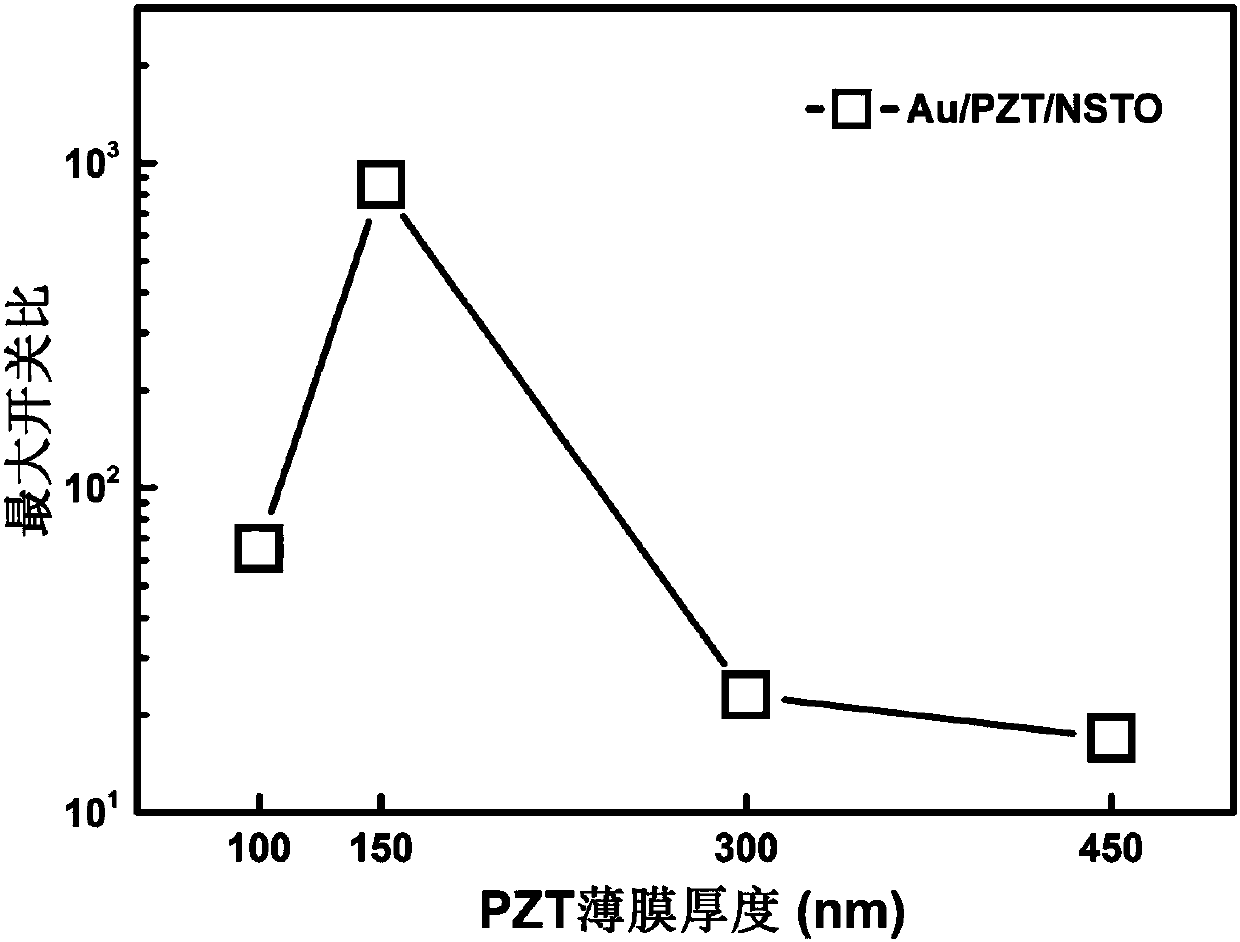

[0026] Embodiment 1 (lead zirconate titanate ferroelectric film thickness is 150nm)

[0027] Step 1: Prepare the solution

[0028] Use deionized water, glacial acetic acid, and isopropanol as solvents. Using lead acetate, zirconium n-propoxide and titanium isopropoxide as solute, according to the Pb:Ti:Zr molar ratio of 5:3:2, weigh lead acetate, zirconium n-propoxide and titanium isopropoxide. Add deionized water, glacial acetic acid and isopropanol respectively at a concentration standard of 0.4M, and then stir at room temperature until the lead acetate, zirconium n-propoxide and titanium isopropoxide are all dissolved to obtain a light yellow transparent solution.

[0029] Step 2: Preparation of film material

[0030] (1) 0.7wt.% Nb-SrTiO 3 The strontium niobium titanate substrate was ultrasonically cleaned in acetone for 20 minutes, and then the strontium niobium titanate substrate was heated in an electric furnace to 1000°C for 120 minutes and then taken out;

[0031]...

Embodiment 2

[0035] Embodiment 2 (lead zirconate titanate ferroelectric film thickness is 100nm)

[0036] Step 1: Prepare the solution

[0037] Use deionized water, glacial acetic acid, and isopropanol as solvents. Using lead acetate, zirconium n-propoxide and titanium isopropoxide as solute, according to the Pb:Ti:Zr molar ratio of 5:3:2, weigh lead acetate, zirconium n-propoxide and titanium isopropoxide. Add deionized water, glacial acetic acid and isopropanol respectively at a concentration standard of 0.4M, and then stir at room temperature until the lead acetate, zirconium n-propoxide and titanium isopropoxide are all dissolved to obtain a light yellow transparent solution.

[0038] Step 2: Preparation of film material

[0039] (1) 0.7wt.% Nb-SrTiO 3 The strontium niobium titanate sheet was cleaned ultrasonically in acetone for 20 minutes, and then the strontium niobium titanate substrate was heated in an electric furnace to 1000°C for 120 minutes and then taken out;

[0040] (2)...

Embodiment 3

[0044] Embodiment 3 (lead zirconate titanate ferroelectric film thickness is 450nm)

[0045] Step 1: Prepare the solution

[0046] Use deionized water, glacial acetic acid, and isopropanol as solvents. Using lead acetate, zirconium n-propoxide and titanium isopropoxide as solute, according to the Pb:Ti:Zr molar ratio of 5:3:2, weigh lead acetate, zirconium n-propoxide and titanium isopropoxide. Add deionized water, glacial acetic acid and isopropanol respectively at a concentration standard of 0.4M, and then stir at room temperature until the lead acetate, zirconium n-propoxide and titanium isopropoxide are all dissolved to obtain a light yellow transparent solution.

[0047] Step 2: Preparation of film material

[0048] (1) 0.7wt.% Nb-SrTiO 3 The strontium niobium titanate substrate was ultrasonically cleaned in acetone for 20 minutes, and then the strontium niobium titanate substrate was heated to 1000°C in an electric furnace and kept for 120 minutes before taking it out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com