Laying hen breeding feeding trough

A technology for feeding troughs and laying hens, applied in the field of feeding troughs for laying hens, can solve the problems of chicken gluttony, polluted chicken trough feed, low selling price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

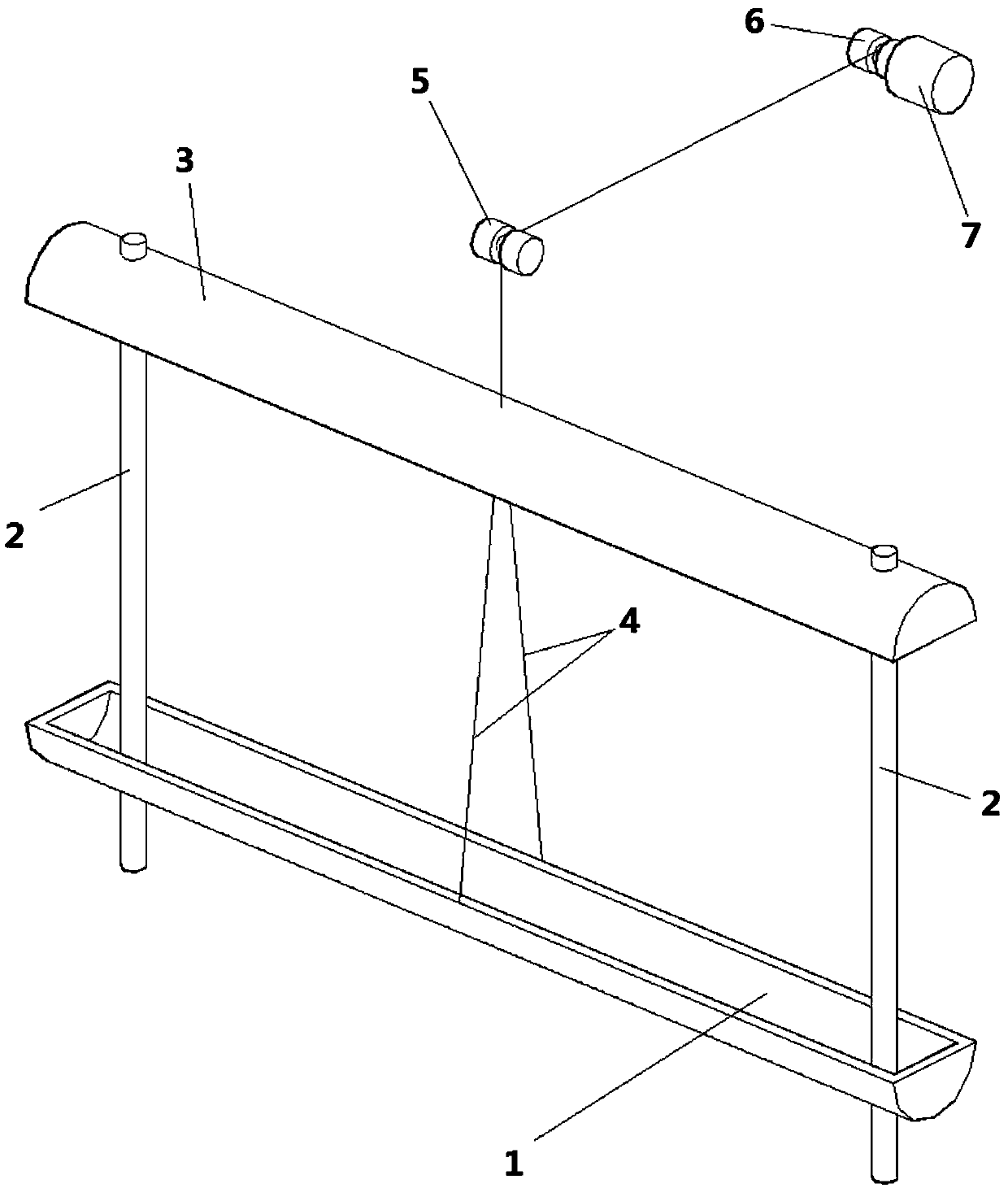

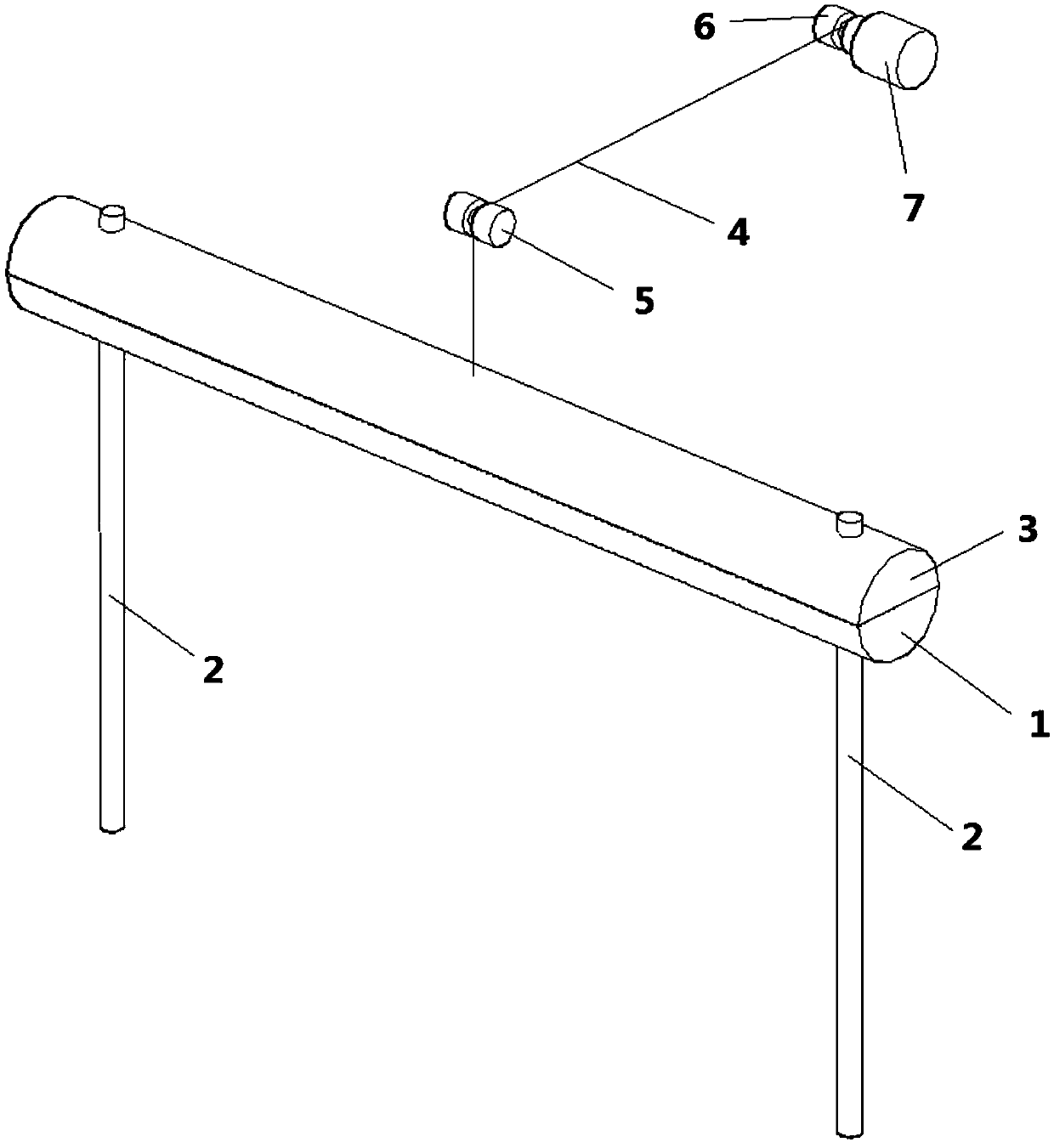

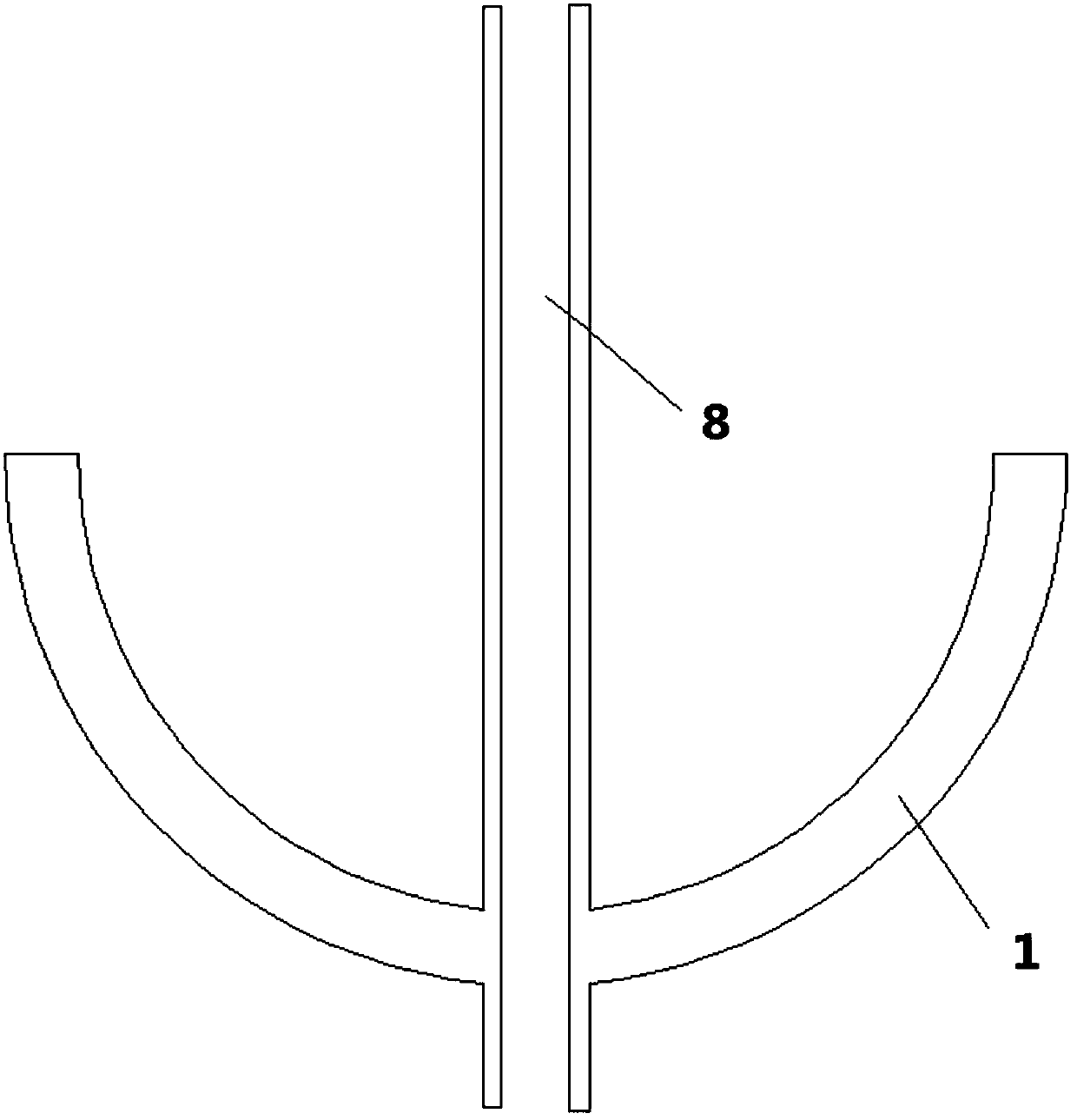

[0023] Such as figure 1 , figure 2 , image 3 As shown, a feeding trough for breeding hens includes a chicken trough body 1, a column 2 and a trough cover 3. The columns 2 are fixed on the ground and pass through the left and right ends of the chicken trough body 1. The main body 1 can slide up and down on the upright column 2. The trough cover 3 is fixed at the top of the upright column 2. The chicken trough body 1 and the trough cover 3 are both semi-cylindrical shapes, which form a complete hollow cylinder after being combined. A rope 4 is fixed at the middle position of the chicken trough body 1. The rope 4 passes upward through the tank cover 3 and passes through the fixed pulley 5 to be finally fixed on the rope retractor 6, and the rope retractor 6 is driven by a motor 7.

[0024] Further, a sealing gasket is provided under the groove cover 3.

[0025] Further, a sleeve 8 is provided at the perforation of the post 2 on the chicken trough body 1, the post 2 passes through t...

Embodiment 2

[0028] The use of a feeding trough for breeding hens of the present invention in combination with feed additives for laying hens can significantly increase the egg production rate and prolong the peak egg production period.

[0029] The feed additive for laying hens is prepared from the following parts by weight of raw materials: 2-5 parts by weight of oysters, 1-2 parts of fish scales, 6-10 parts of red dates, 1-2 parts of tangerines, and 1-3 parts of Sophora japonica leaves, Polygala 2-5 parts, Poria cocos 6-12 parts, Rehmannia glutinosa 5-10 parts, Yejiao vine 2-4 parts, Schisandra 2-5 parts, wasp pupae 3-6 parts, insect jelly 10-15 parts.

[0030] Further, the preferred parts by weight of each raw material are: 5 parts of oysters, 2 parts of fish scales, 8 parts of red dates, 1 part of tangerine collaterals, 1.5 parts of Sophora japonica leaves, 3 parts of Polygala, 10 parts of Poria cocos, 8 parts of Rehmannia glutinosa, 3 parts of Yejiao vine Servings, 3 servings of Schisandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com