Ship propulsion appliance

A technology for propellers and ships, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of long time, high oil cylinder installation and maintenance costs, ship collision, etc., and achieves convenient use, simple structure, and high steering efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

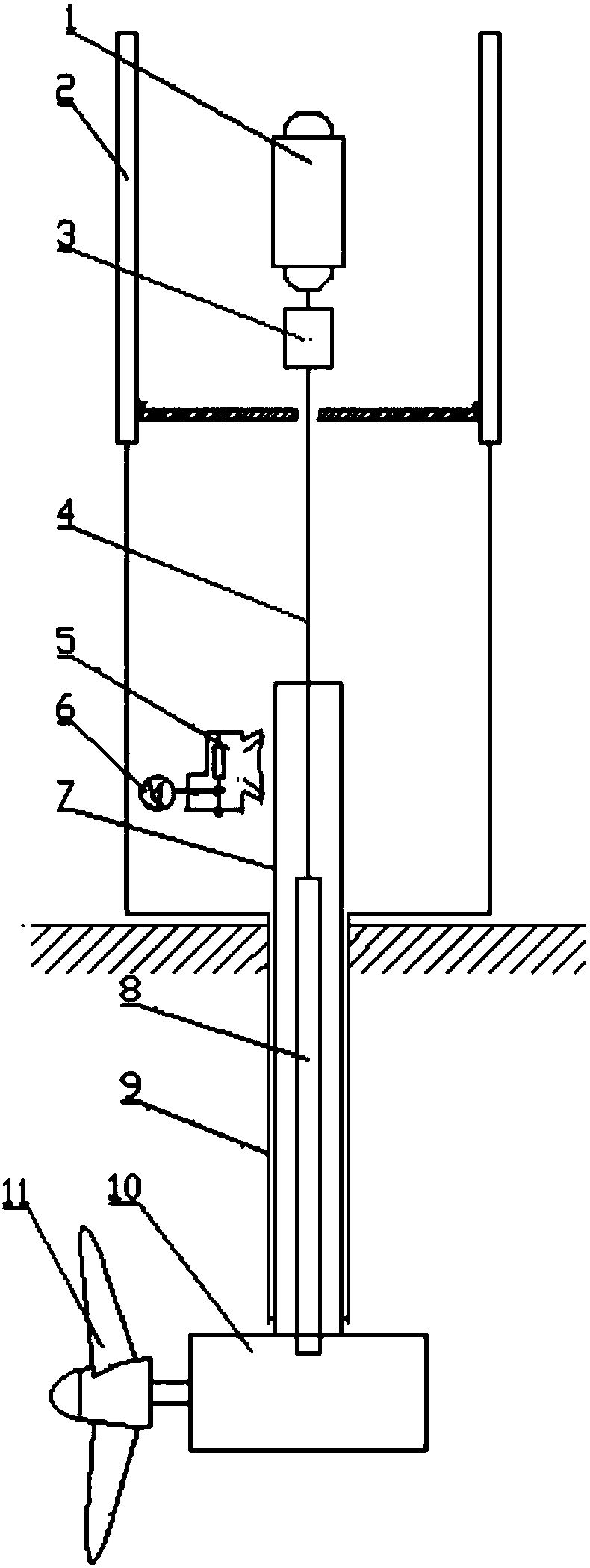

[0021] When the propeller is driving, the propulsion motor 1 transmits the power to the spline shaft 4 through the coupling 3, and the spline shaft 4 transmits the power to the input shaft of the underwater gearbox 10 through the hollow rotating shaft 8, thereby driving the propeller 11 rotation propulsion.

Embodiment 2

[0023] When the propeller expands and contracts up and down, the cylinder 2 drives the telescopic cylinder shaft 9 to expand and contract up and down, and the telescopic cylinder shaft 9 drives the underwater gear box 10 to expand and contract up and down through the rotary cylinder shaft 7. At this time, the spline shaft 4 slides in the hollow rotating shaft 8, Complete the up and down expansion and contraction of propeller propeller 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com