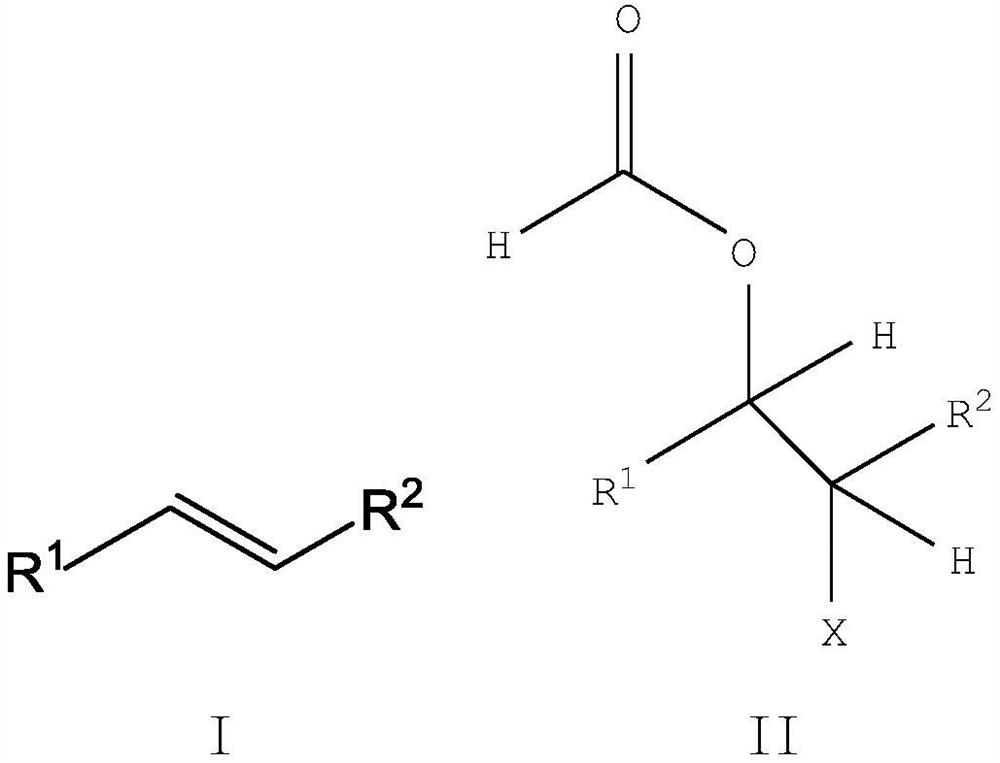

A method for synthesizing β-haloformate compounds

A technology of ester compounds and haloformic acid, which is applied in the field of synthesis of organic compounds, can solve problems such as high toxicity, environmental pollution costs, and poor stability of halogen sources, and achieve the effects of simple operation, environmental friendliness, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

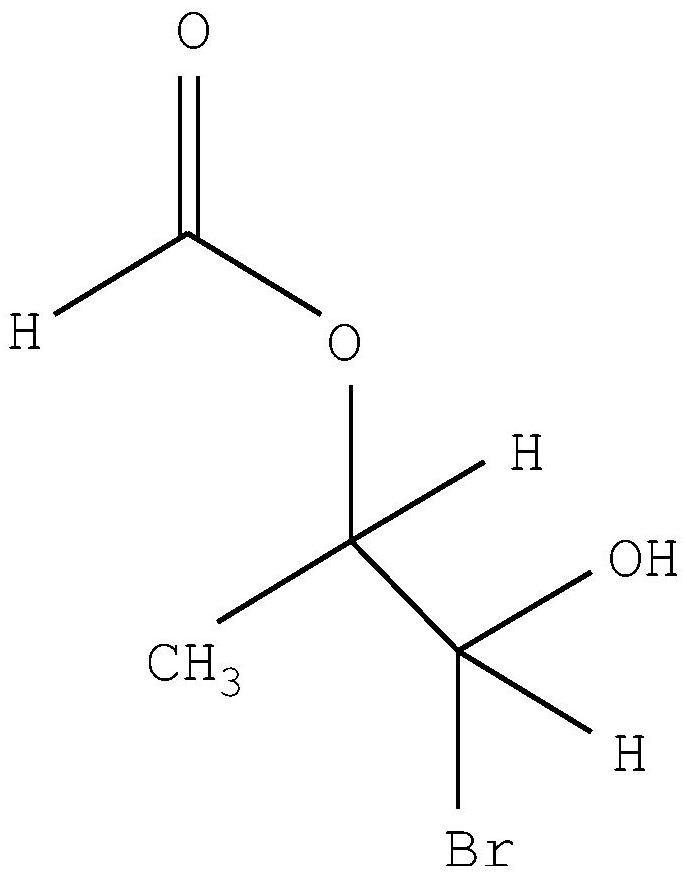

Embodiment 1

[0031]

[0032] Add 2mmol (0.172g) of 3-methyl-2-buten-1-ol and 1.8mmol (0.2142g) of potassium bromide into a 50mL three-necked flask, then add 10mL of formic acid as a solvent, and then add 0.8g of bromate The intercalated zinc-aluminum hydrotalcite ZnAl-BrO3--LDHs was magnetically stirred at 40°C for 4 hours. After the reaction is over, use a centrifuge at 6500r / min to centrifuge to remove the zinc-aluminum hydrotalcite solid, place the resulting liquid in a separatory funnel, add dichloromethane and deionized water, and extract the organic matter obtained from the reaction into the dichloromethane phase to obtain Column chromatography silica gel was added to the solution, the solvent was distilled off under reduced pressure, and the remaining mixture was separated by column chromatography, using a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 10:1 as the eluent, and the eluted product containing the product was collected. The solvent was disti...

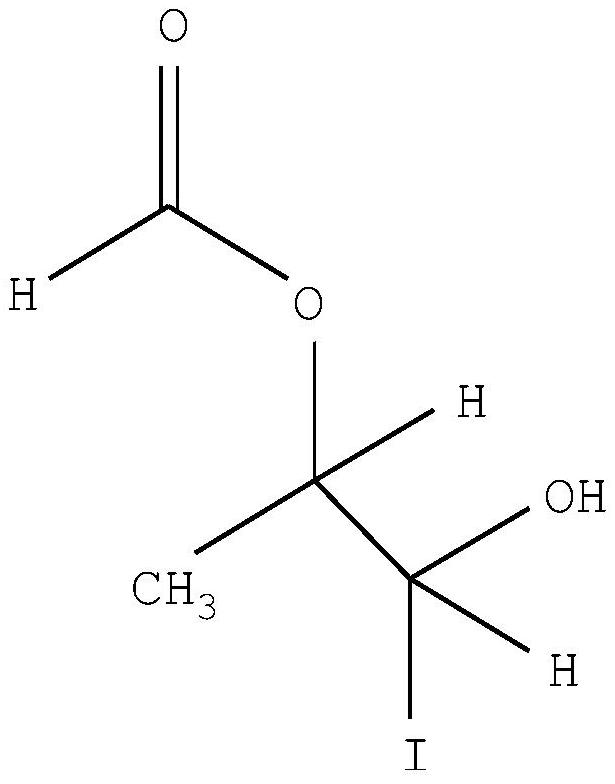

Embodiment 2

[0035]

[0036] Add 2mmol (0.172g) of 3-methyl-2-buten-1-ol and 2.2mmol (0.3652g) of potassium iodide into a 50mL three-necked flask, then add 10mL of formic acid as a solvent, and then add 0.8g of bromate for intercalation ZnAl-BrO 3 -- LDHs, stirred magnetically at 25° C. for 6 hours, followed by TLC to complete the reaction. After the reaction is over, use a centrifuge at 6500r / min to centrifuge to remove the zinc-aluminum hydrotalcite solid, place the resulting liquid in a separatory funnel, add dichloromethane and deionized water, and extract the organic matter obtained from the reaction into the dichloromethane phase to obtain Column chromatography silica gel was added to the solution, the solvent was distilled off under reduced pressure, and the remaining mixture was separated by column chromatography, using a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 10:1 as the eluent, and the eluted product containing the product was collected. The...

Embodiment 3

[0039]

[0040] Add 2mmol (0.210g) of 2-vinylpyridine and 1.8mmol (0.2142g) of potassium bromide into a 50mL three-necked flask, then add 10mL of formic acid as a solvent, and then add 0.8g of bromate-intercalated zinc aluminum hydrotalcite ZnAl- BrO3--LDHs, magnetic stirring at 40°C for 2.5 hours. After the reaction is over, use a centrifuge at 6500r / min to centrifuge to remove the zinc-aluminum hydrotalcite solid, place the resulting liquid in a separatory funnel, add dichloromethane and deionized water, and extract the organic matter obtained from the reaction into the dichloromethane phase to obtain Column chromatography silica gel was added to the solution, the solvent was distilled off under reduced pressure, and the remaining mixture was separated by column chromatography, using a mixed solvent of petroleum ether and ethyl acetate with a volume ratio of 2:1 as the eluent, and the eluted product containing the product was collected. The solvent was distilled off from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com