A kind of manufacturing process of epoxy resin for temperature sensor

A technology of temperature sensor and epoxy resin, which is applied in thermometer parts, thermometers, instruments, etc., can solve the problems of easy cracking and affect the service life of the measurement data accuracy sensor. Excellent effect of resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

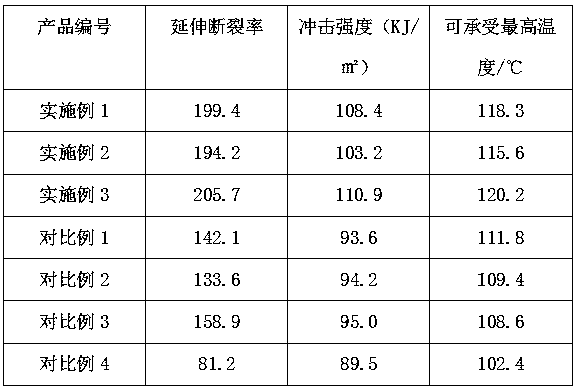

Examples

Embodiment 1

[0018] In the reaction kettle, add 100Kg of polyurethane modified epoxy resin, 45Kg of bisphenol A type epoxy acrylate, 5Kg of glycidyl methacrylate, 0.3Kg of vinyl tri(dimethylsiloxane) silane, metal nickel Chelating Sepharose 6FF1Kg, (2-methanoylphenyl) (1R,2S)-1-amino-2-vinylcyclopropane methyl 4-methylbenzenesulfonate 0.05Kg, mix well, in React at 75°C for 7 hours to obtain epoxy resin product.

Embodiment 2

[0020] In the reaction kettle, add 100Kg of polyurethane modified epoxy resin, 30Kg of bisphenol A type epoxy acrylate, 2Kg of glycidyl methacrylate, 0.1Kg of vinyl tri(dimethylsiloxane) silane, metal nickel Chelating Sepharose 6FF 0.5Kg, (2-methanoylphenyl)(1R,2S)-1-amino-2-vinylcyclopropane methyl 4-methylbenzenesulfonate 0.01Kg, mix well , and reacted at 65°C for 4 hours to obtain epoxy resin products.

Embodiment 3

[0022] In the reaction kettle, add 100Kg of polyurethane modified epoxy resin, 60Kg of bisphenol A type epoxy acrylate, 8Kg of glycidyl methacrylate, 0.5Kg of vinyl tri(dimethylsiloxane) silane, metal nickel Chelating Sepharose 6FF 1.5Kg, (2-methanoylphenyl)(1R,2S)-1-amino-2-vinylcyclopropane methyl 4-methylbenzenesulfonate 0.1Kg, mix well , and reacted at 90°C for 10 hours to obtain epoxy resin products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com