Inspection device for coaxiality of cylinder cover valve base hole and guide pipe bottom hole

A valve seat and cylinder head technology is applied in the field of the coaxiality check tool for the valve seat hole of the cylinder head to the bottom hole of the guide tube, which can solve the problems of unsuitable batch testing, long logistics and transportation distance, and high economic cost, so as to improve the measurement efficiency. and accuracy, easy operation, and the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

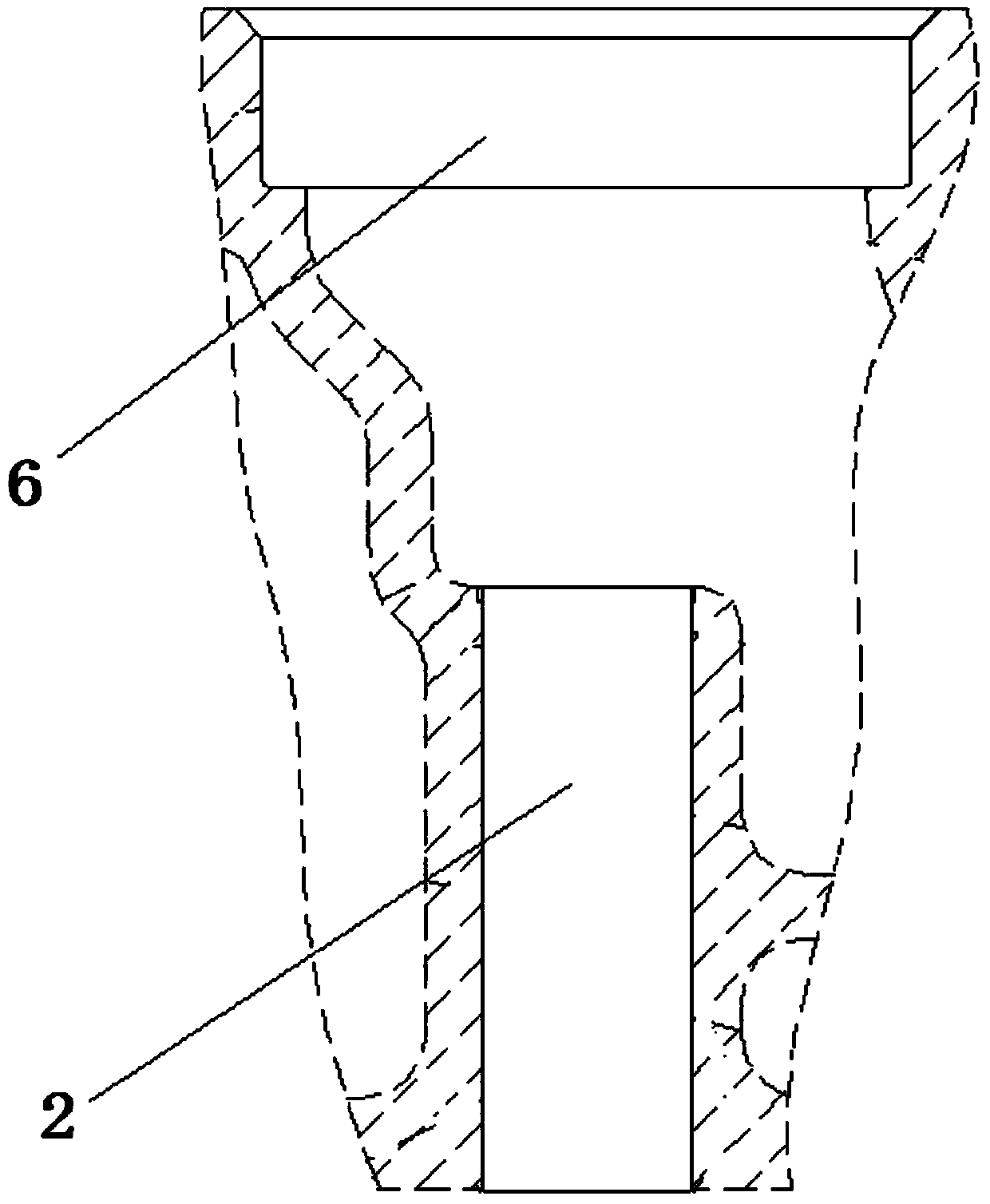

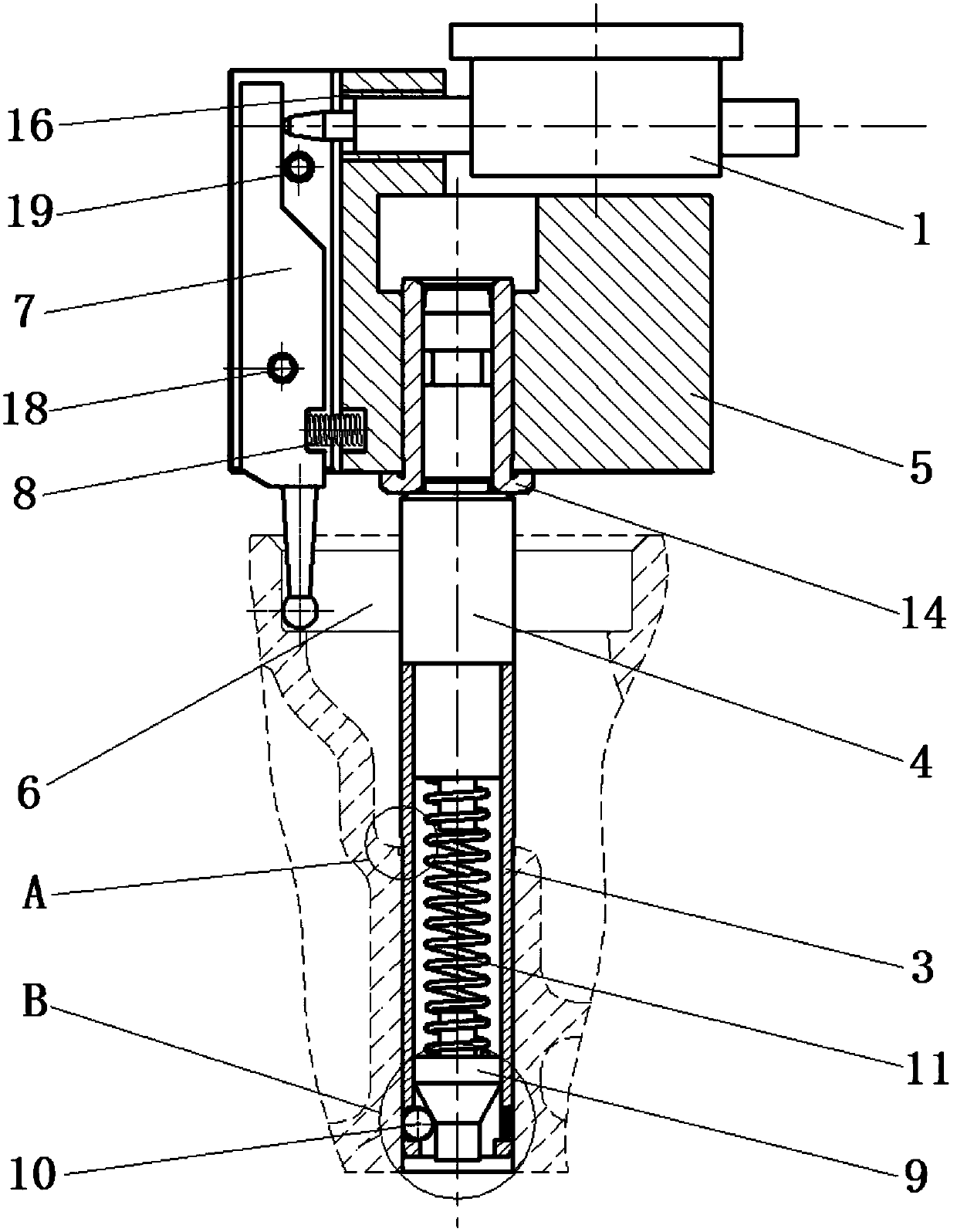

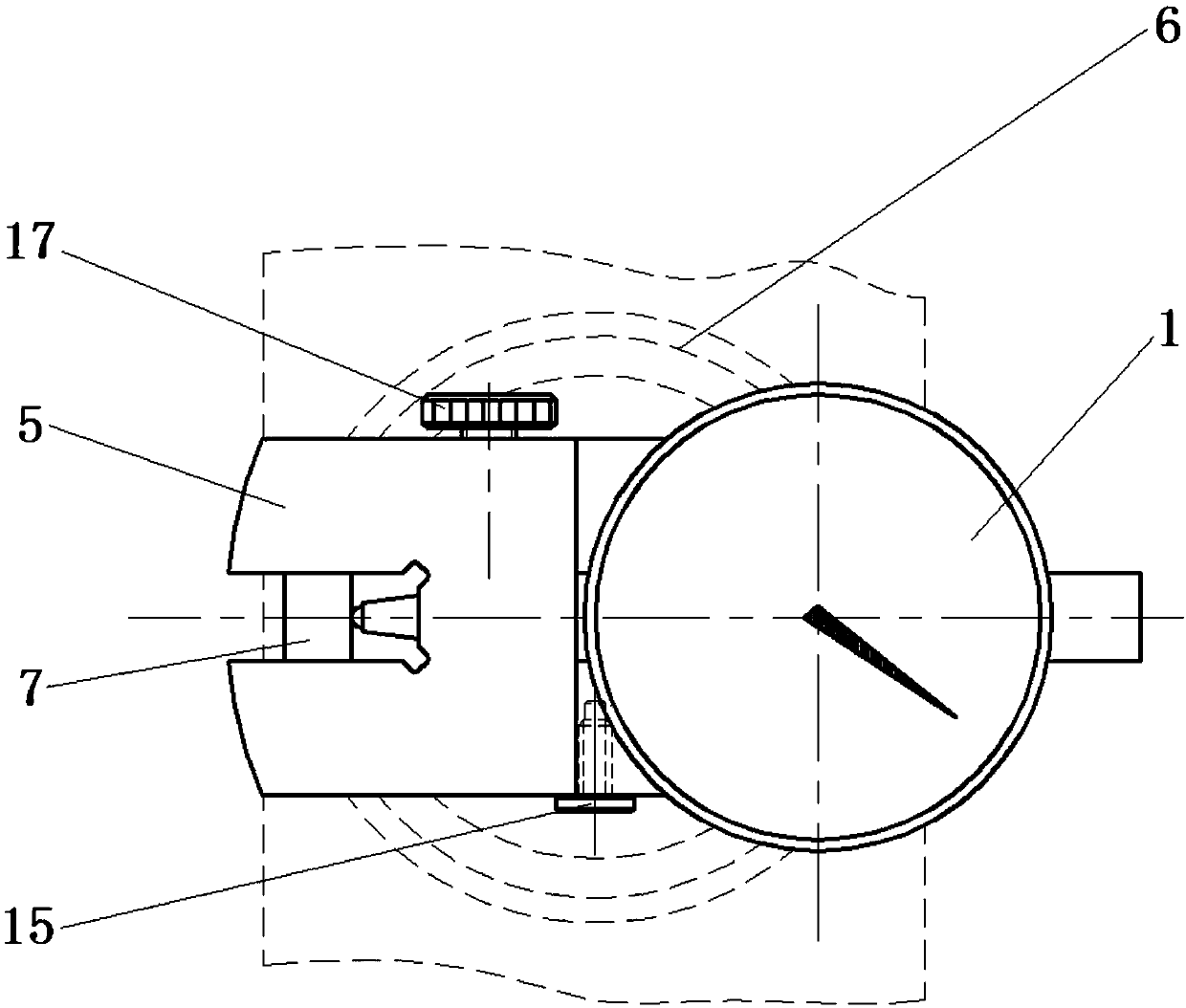

[0031] refer to Figure 1-7 , a cylinder head valve seat hole of the present invention to the coaxiality of the conduit bottom hole inspection tool, including a dial indicator 1, and also includes a hollow structure mandrel 3 that can be inserted into the conduit bottom hole 2 and inserted into the The mandrel 4 at one end of the mandrel 3 and the rotatable inspection tool seat 5 sleeved at one end of the mandrel 4, wherein the lower part of the mandrel 3 and the bottom hole 2 of the conduit are clearance fit, which is convenient for insertion and protection. The bottom hole 2 of the conduit is not damaged, the mandrel 4 is located at the upper end of the mandrel 3, and the inspection tool seat 5 has a U-shaped groove, which is located at the upper end of the mandrel 4 and can rotate relative to the axis of the mandrel 4. One side of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com