Automatic detection device for one interface of solid rocket engine

An automatic detection device and solid rocket technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, can solve problems such as low work efficiency, complicated operation steps, and workpiece contamination, and achieve objective and accurate detection results and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment provides a specific implementation of a solid rocket motor-interface automatic detection device of the present invention.

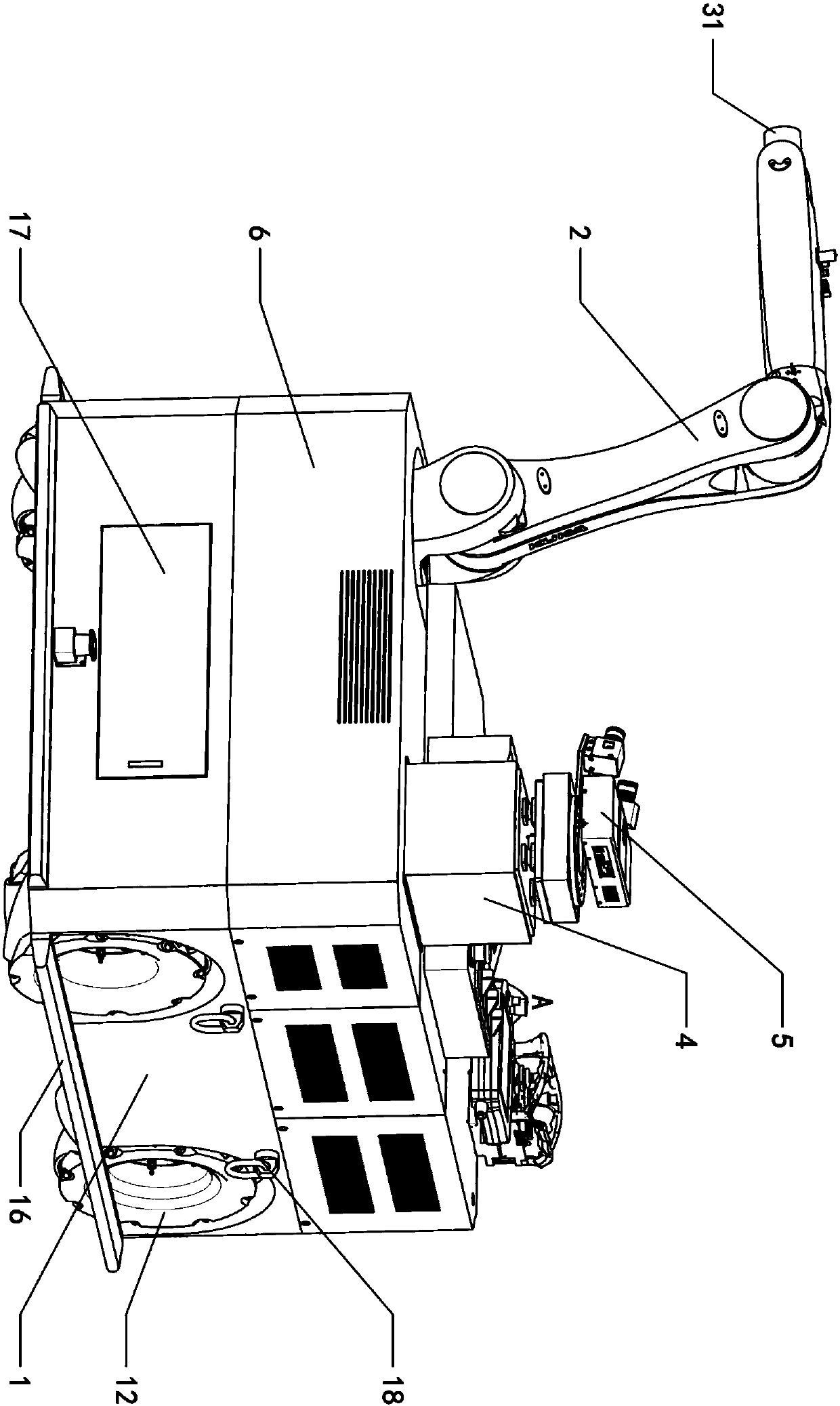

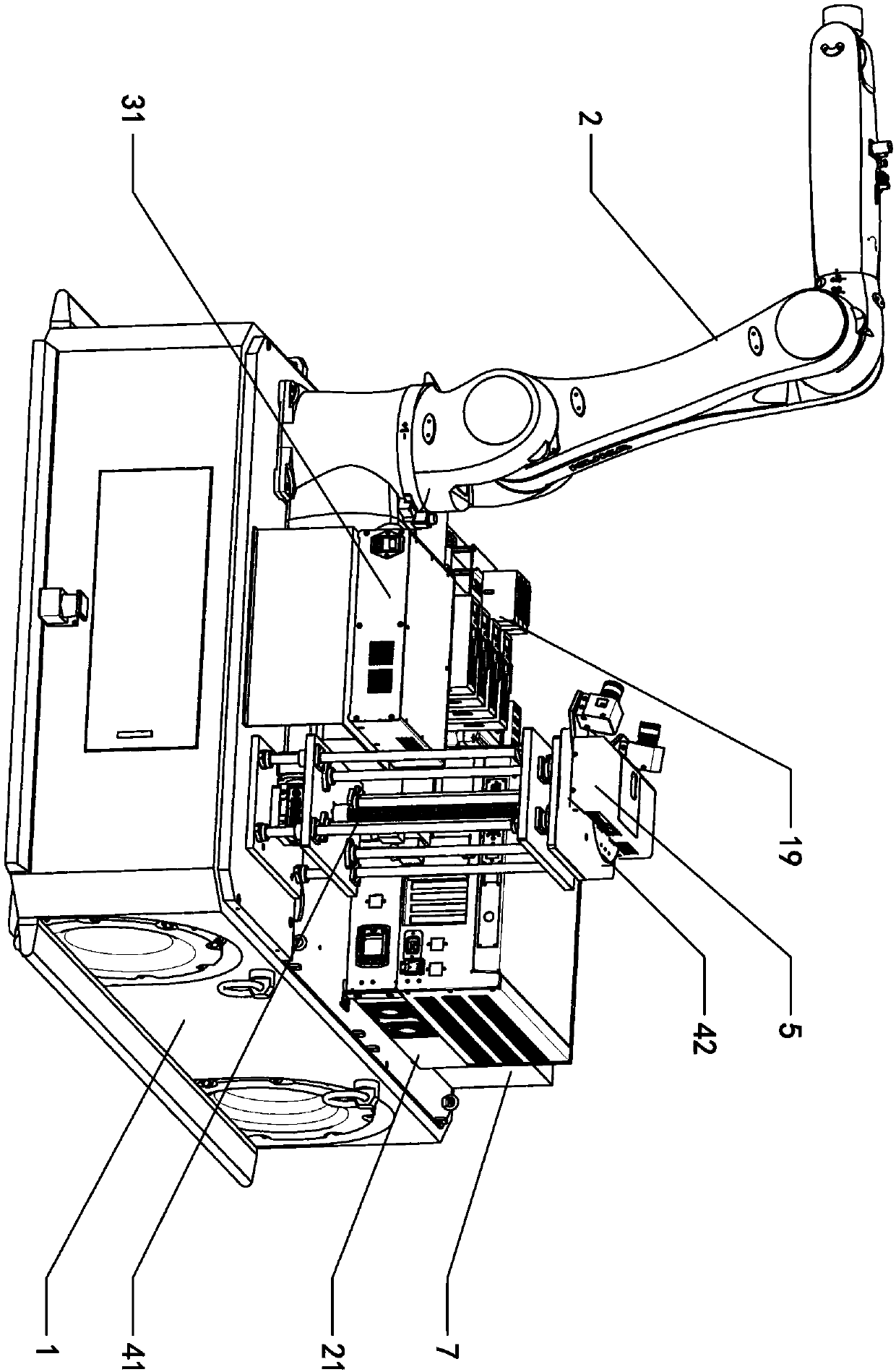

[0021] Such as figure 1 As shown, the overall structure of the solid rocket motor-interface automatic detection device is a cuboid, the bottom is provided with an omnidirectional mobile platform 1, the top of the omnidirectional mobile platform 1 is provided with a cover plate 6, and the mechanical arm 2 arranged on the omnidirectional mobile platform 1 And the lifting rotating device 4 protrudes upwards from the cover plate 6 top. The solid rocket motor-interface automatic detection device also includes components such as an ultrasonic detection device, a 3D scanner 5 and an industrial computer 7 .

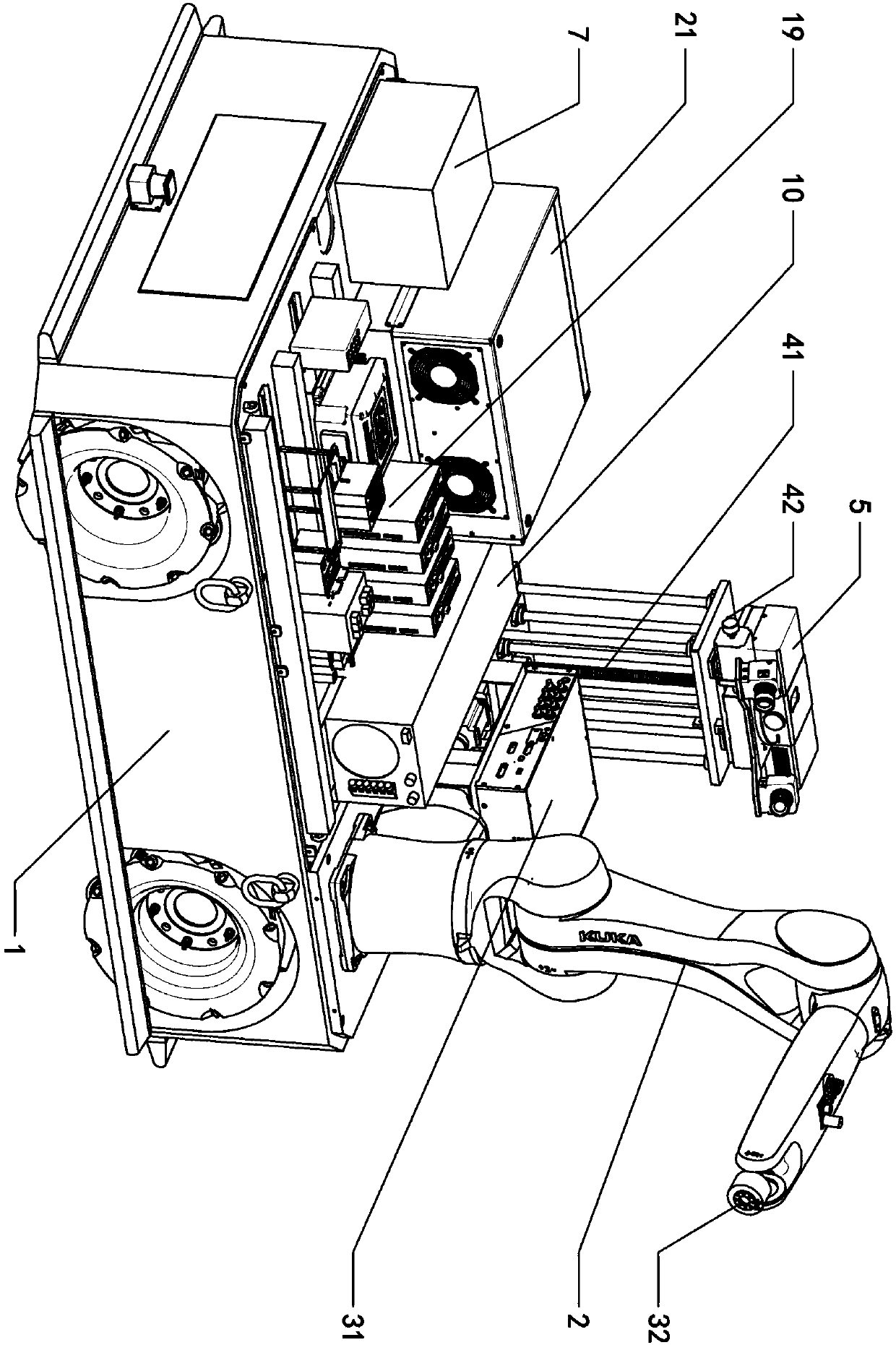

[0022] Such as figure 2 with image 3 As shown, the ultrasonic detection device includes an ultrasonic detection host 31 arranged inside the cover plate 6 , and an ultrasonic probe 32 arranged at the front end of the mechanical arm...

Embodiment 2

[0027] This embodiment provides a specific implementation of the electrical connection between the components of the solid rocket motor-interface automatic detection device described in Embodiment 1.

[0028] Such as Figure 4 Shown is a schematic diagram of the electrical connections between the components of the device. The industrial computer 7 communicates with each component mainly through the network port, RS232 serial port, RS485 serial port, USB port and the like. At the same time, a VGA signal channel for display output is provided between the industrial computer 2 and the touch screen, and an HDMI port for transmitting surveying and mapping information collected by the 3D scanner 5 is also provided between the industrial computer 2 and the 3D scanner 5 . The travel switch signal in the safety touch edge 16 is sent to the industrial computer 7 through the RSA232 serial port after being transformed by the PLC circuit.

Embodiment 3

[0030] This embodiment provides a specific implementation of the selection of each component of a solid rocket motor-interface automatic detection device described in Embodiment 1, as shown in the following table:

[0031]

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com