Baffled acoustic metamaterial silencer, and preparation and assembling methods thereof

An acoustic metamaterial and muffler technology, which is applied in the direction of sound-generating equipment and instruments, can solve the problems of incompetent low-frequency broadband noise conditions and narrow effective muffling bandwidth, and achieves enhanced work stability, improved muffling performance, and reduced noise volume. level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

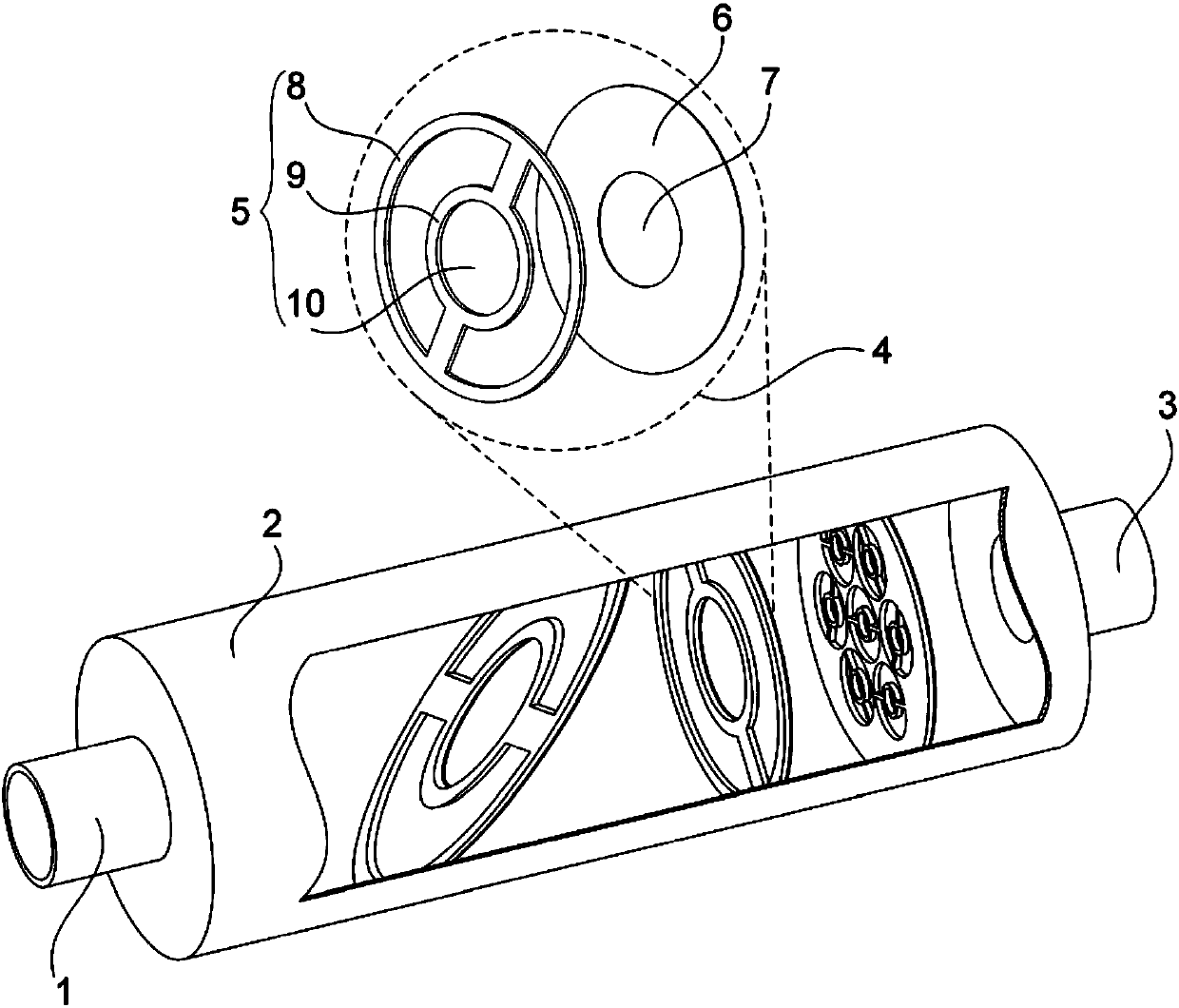

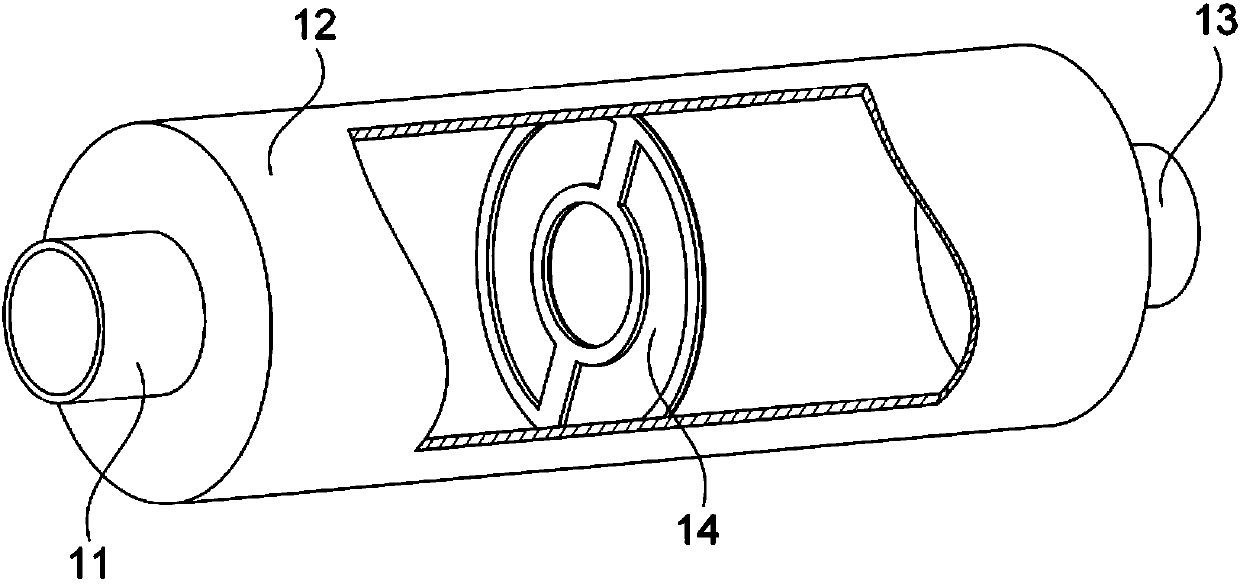

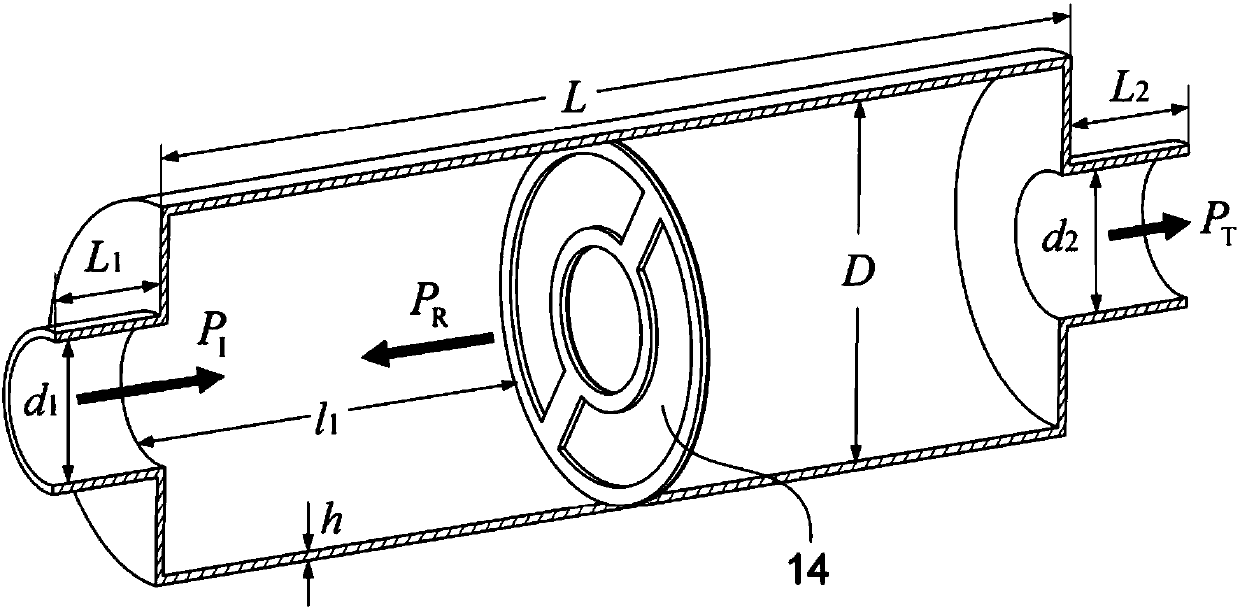

[0113] Embodiment 1 Basic acoustic metamaterial baffle muffler

[0114] Attached below Figure 2-8 The structural parameters, preparation method, performance calculation and measurement, and mechanism analysis of the basic acoustic metamaterial baffle muffler are described.

[0115] 1. Structural parameters and preparation methods

[0116] Use SPCC cold-rolled steel plate to form one piece by laser cutting, such as figure 2 The frame of the basic PAMB (14) shown is glued with a film on one side and perforated. The basic PAMB is positioned inside the expansion chamber (12) through a sleeve, and the outer cavity of the muffler is assembled through a flange connection. Wherein, the expansion cavity (12) has a length of 250mm and an inner diameter of 46mm; the inlet pipe (11) has a length of 15mm and an inner diameter of 10mm; the outlet pipe (13) has a length of 15mm and an inner diameter of 10mm; the muffler has uniform wall thickness and a thickness of 3mm; The distance bet...

Embodiment 2

[0131] Embodiment 2 contains the muffler of two groups of acoustic metamaterial baffles

[0132] 1. Structural parameters

[0133] Such as Figure 10 As shown, the muffler containing two sets of PAMBs described in Example 2 of the present invention is formed by installing a set of PAMBs on the basis of the basic acoustic metamaterial baffle muffler described in Example 1. The structural size and material composition of the two groups of PAMBs (30) and (31) are not exactly the same, and they are respectively aimed at different frequency bands of the noise-absorbing troughs. Wherein, the frame of the first group of PAMBs (30) is circular, with an outer diameter of 46mm, an inner diameter of 40mm, and a thickness of 2mm; the outer diameter of the constrained body with holes is 18mm, and the diameter of the constrained body hole is 12mm; the perforated film The thickness is 0.05mm, and the diameter of the through hole is also 12mm; the double-arm connecting rod between the const...

Embodiment 3

[0137] Embodiment 3 Sound-absorbing material closed impedance compound muffler

[0138] 1. Structural parameters

[0139] Such as Figure 13 As shown, the sound-absorbing material closed impedance composite type muffler composed of two layers of PAMB filled with sound-absorbing material according to Embodiment 2 of the present invention includes a group of sound-absorbing material sealed impedance composite type baffles (35), which are composed of It is composed of two layers of PAMB with sound-absorbing material sandwiched between them. Wherein, the first layer of PAMB (comprising frame (37) and perforated film (36)) is connected with the second layer of PAMB (comprising frame (41) and perforated film (42)) through bracket (40), and the periphery of bracket (40) is laid An annular covering film (39), filled with sound-absorbing material (38) between the annular covering film (39) and the inner wall surface of the muffler cavity (34). Wherein, the structural size and materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com