Impedance combined type dust blowing gun silencing device and method based on perforation resonance

A noise reduction device and impedance compounding technology, which is applied in the direction of sound-generating devices and instruments, can solve the problems of reduced wind speed, small size, and large pressure loss at the outlet of the dust blower, and achieve reduced radiation noise, excellent noise reduction, and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

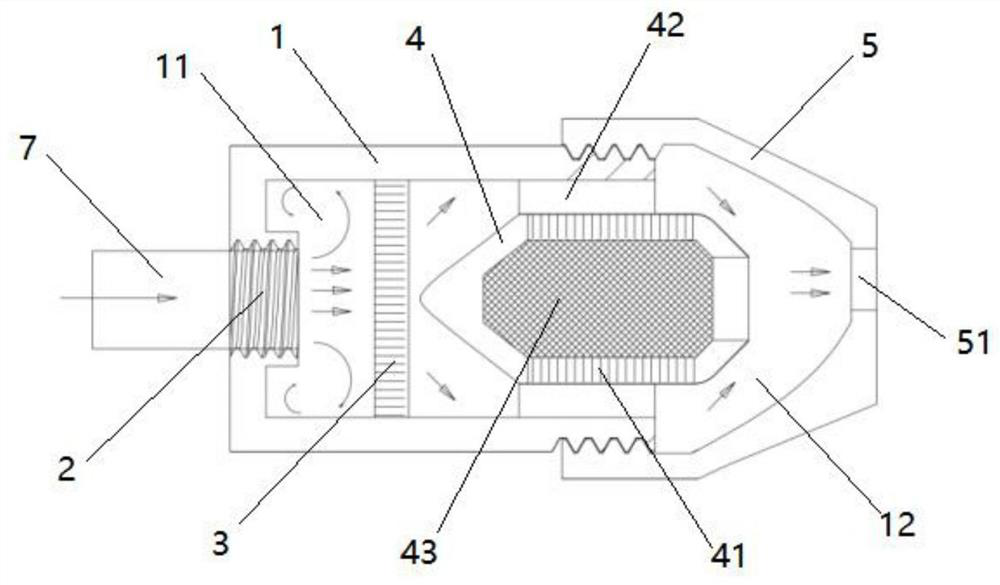

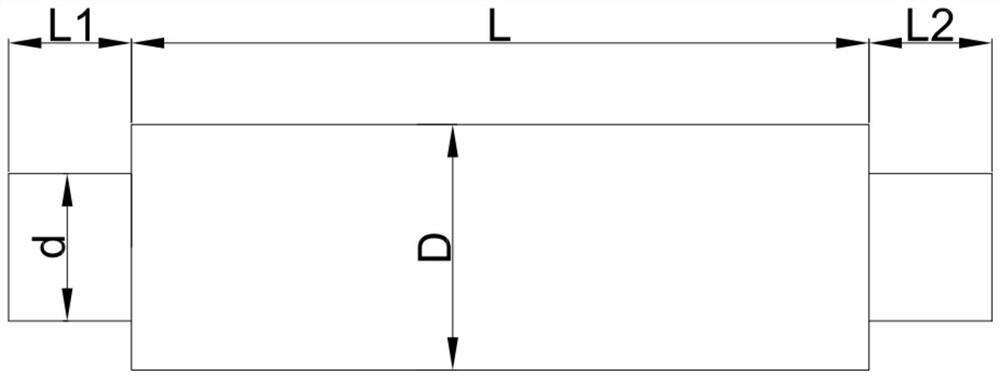

[0052] like Figure 1-Figure 5 As shown, one embodiment of the present invention provides a perforated resonance-based impedance composite dust blowing gun noise reduction device, comprising an outer casing 1, a dust blowing interface 2 arranged at the bottom of one end of the outer casing 1, The microporous resonance plate 3, the muffler unit 4 and the cluster nozzle 5 that are detachably installed at the end of the outer casing 1 away from the dust blowing gun interface 2 are provided at intervals between the outer casing 1 and the dust blowing gun interface 2; A first sound-absorbing and diffusing cavity 11 is formed between the inner wall of the outer casing 1 and the microporous resonance plate 3 at one end of the dust blowing interface 2, and the dust blowing interface 2 extends into the first An inner tube is formed in a sound-absorbing and diffusing cavity 11. At the same time, a second sound-absorbing and diffusing cavity 12 is formed between the microporous resonant ...

Embodiment 2

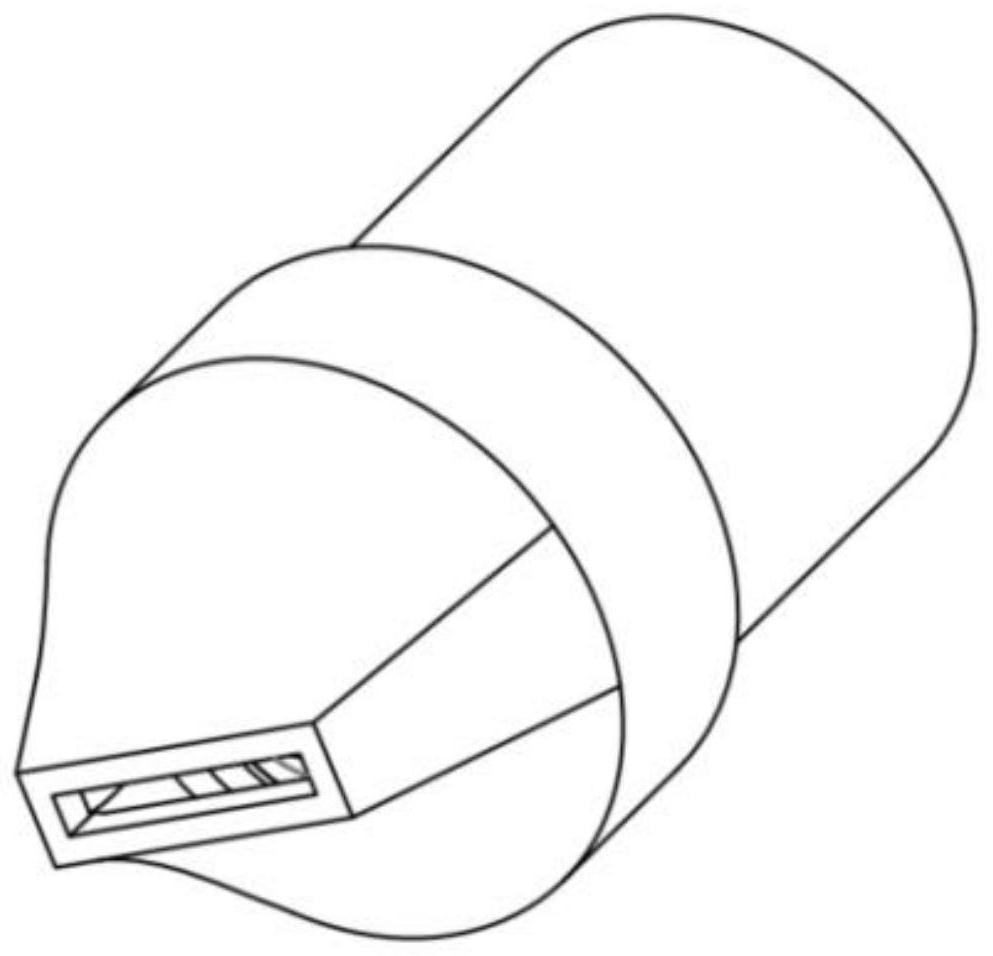

[0067] like Image 6 and Figure 7 As shown in the figure, this embodiment is basically the same as Embodiment 1, and the main difference is that: a perforated resonance-based impedance composite dust blowing gun noise reduction device of this embodiment includes an outer casing 1 with openings at both ends, a detachable The base 6 outside one end of the outer casing 1, the dust blowing gun interface 2 located in the center of the base 6 and communicating with the inside of the outer casing 1, and the dust blowing gun interface 2 located inside the outer casing 1 and the dust blowing gun The microporous resonance plate 3, the muffler unit 4 and the cluster nozzle 5 which are detachably installed on the end of the outer casing 1 away from the dust blowing gun interface 2 are arranged at intervals; the inner wall of one end of the outer casing 1 away from the base 6 There is an L-shaped slot, one end of the support partition 42 is clipped in the L-shaped slot, and the inner wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com