Arrangement structure and winding method of transformer with delta-connected third winding

A technology of transformers and windings, applied in the manufacture of inductors/transformers/magnets, transformers/inductors coils/windings/connections, and coil manufacturing, etc., can solve the problems of no voltage form, high design cost, different lead-out methods, etc. Reduce design costs, enrich wiring types, and ensure the effect of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

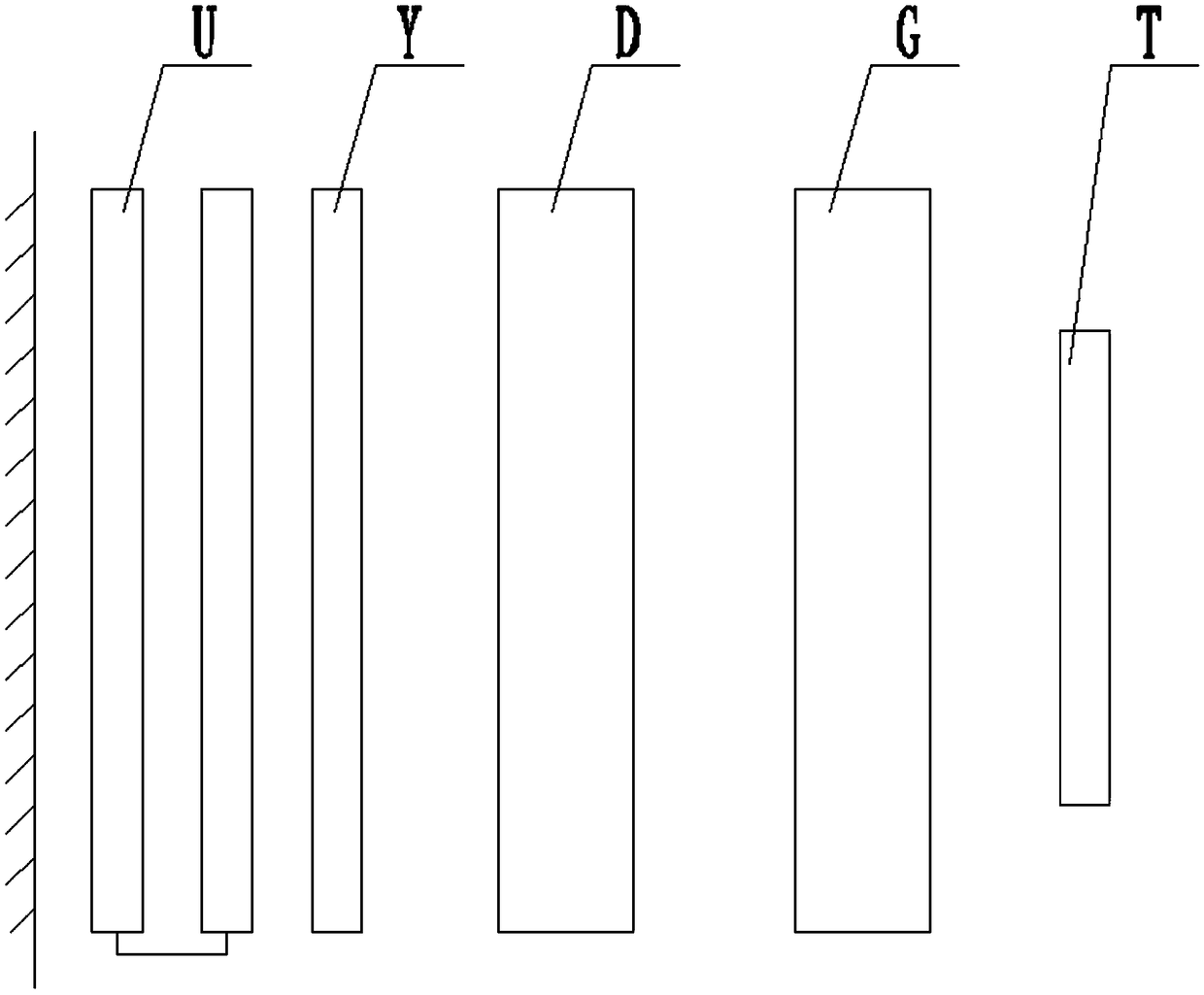

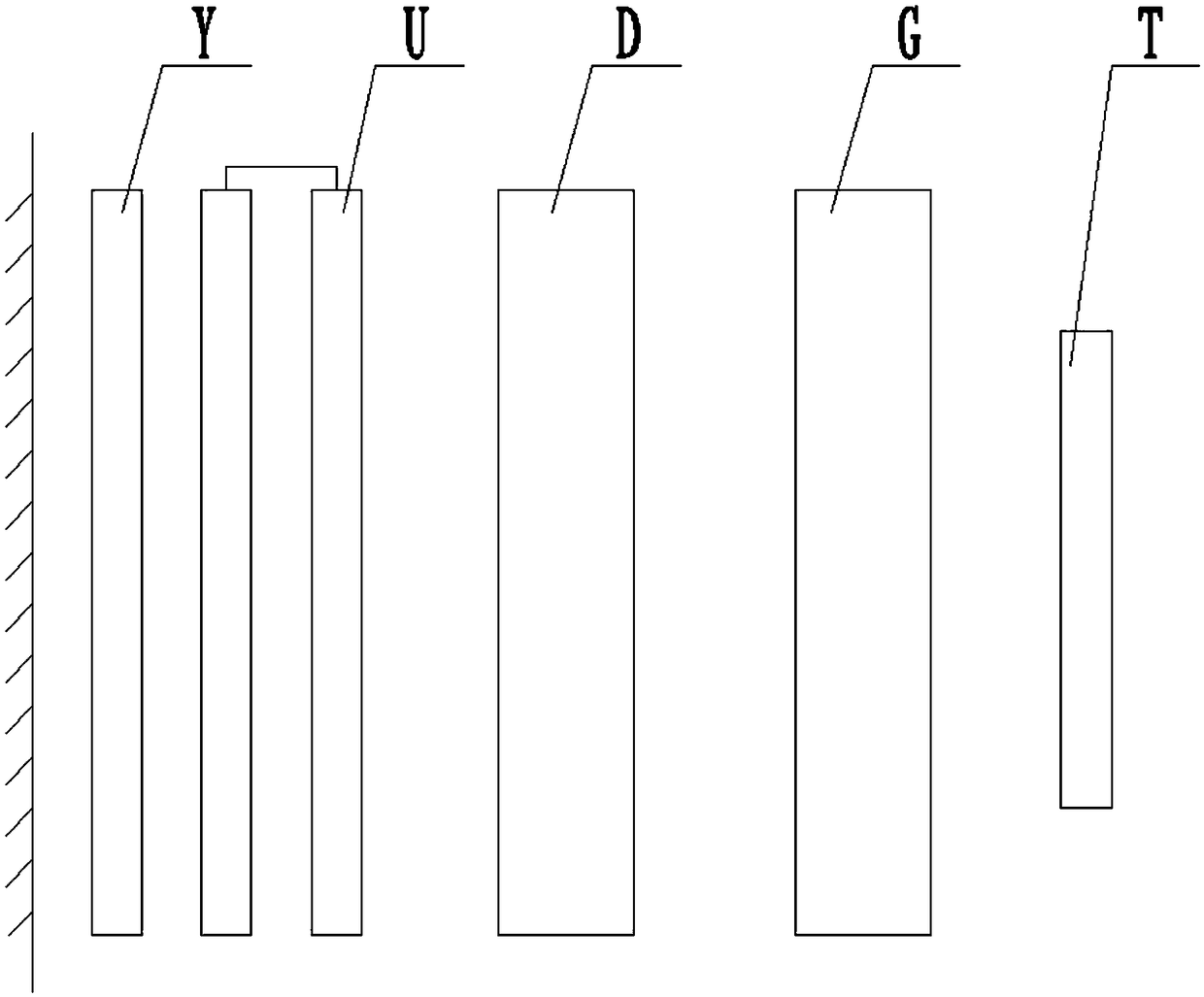

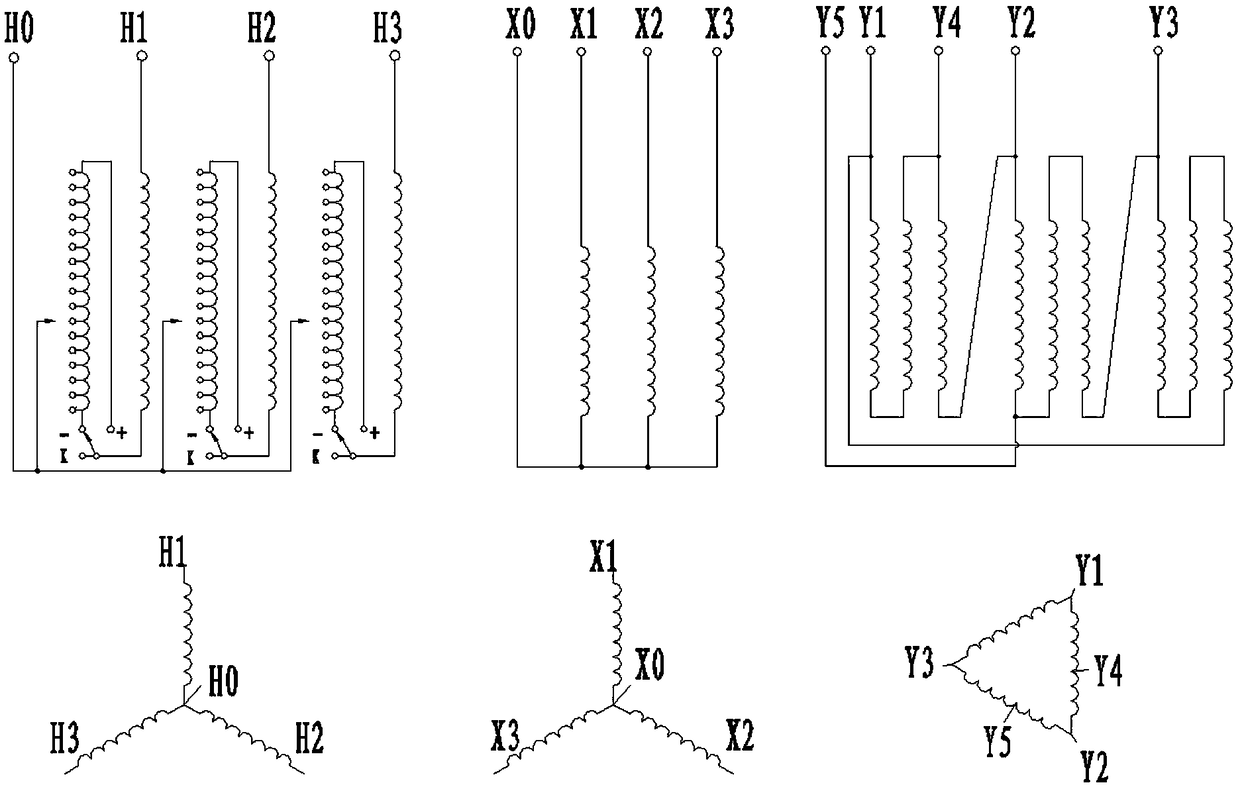

[0029] Such as figure 1 As shown in the present invention, a transformer arrangement structure with delta connection of the third winding includes the first to third iron core columns, and has a U-shaped winding U, a single-layer cylindrical winding Y, a low-voltage winding D, a high-voltage winding G and a high-voltage regulator Compression winding T, wherein, the U-shaped winding U and the single-layer cylindrical winding Y form the third winding of the first and third iron core columns, and the winding arrangement structure of the first iron core column and the third iron core column is U-shaped Winding-single-layer cylindrical winding-low-voltage winding-high-voltage winding-high-voltage voltage regulating winding, and the upper outgoing line of the U-shaped winding is connected with the upper outgoing line of the single-layer cylindrical windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com