Multi-zoned paddle screen apparatus

A technology for screening equipment and paddles, which is applied in filter screens, centrifuges, separation methods, etc., can solve problems such as high capital operating costs, high equipment maintenance costs, and screening blockages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Corn wet milling equipment converts corn kernels into several different co-products such as germ (for oil extraction), gluten feed (high fiber animal feed), gluten meal (high protein animal feed) and starch-based Products (such as ethanol or butanol, high fructose corn syrup, or food and industrial starches). Typical corn wet milling equipment may include a fiber separation step in which a slurry of water, gluten and starch is passed through a series of wire meshes to separate the fiber from the starch and gluten and to wash the fiber so that it does not Contains gluten and starch. Similarly, a typical dry milling process may include a centrifugation step in which the fibers are similarly filtered or separated from the slurry. Those of ordinary skill in the art will appreciate that typical corn wet and dry milling processes can be manipulated and modified, if desired.

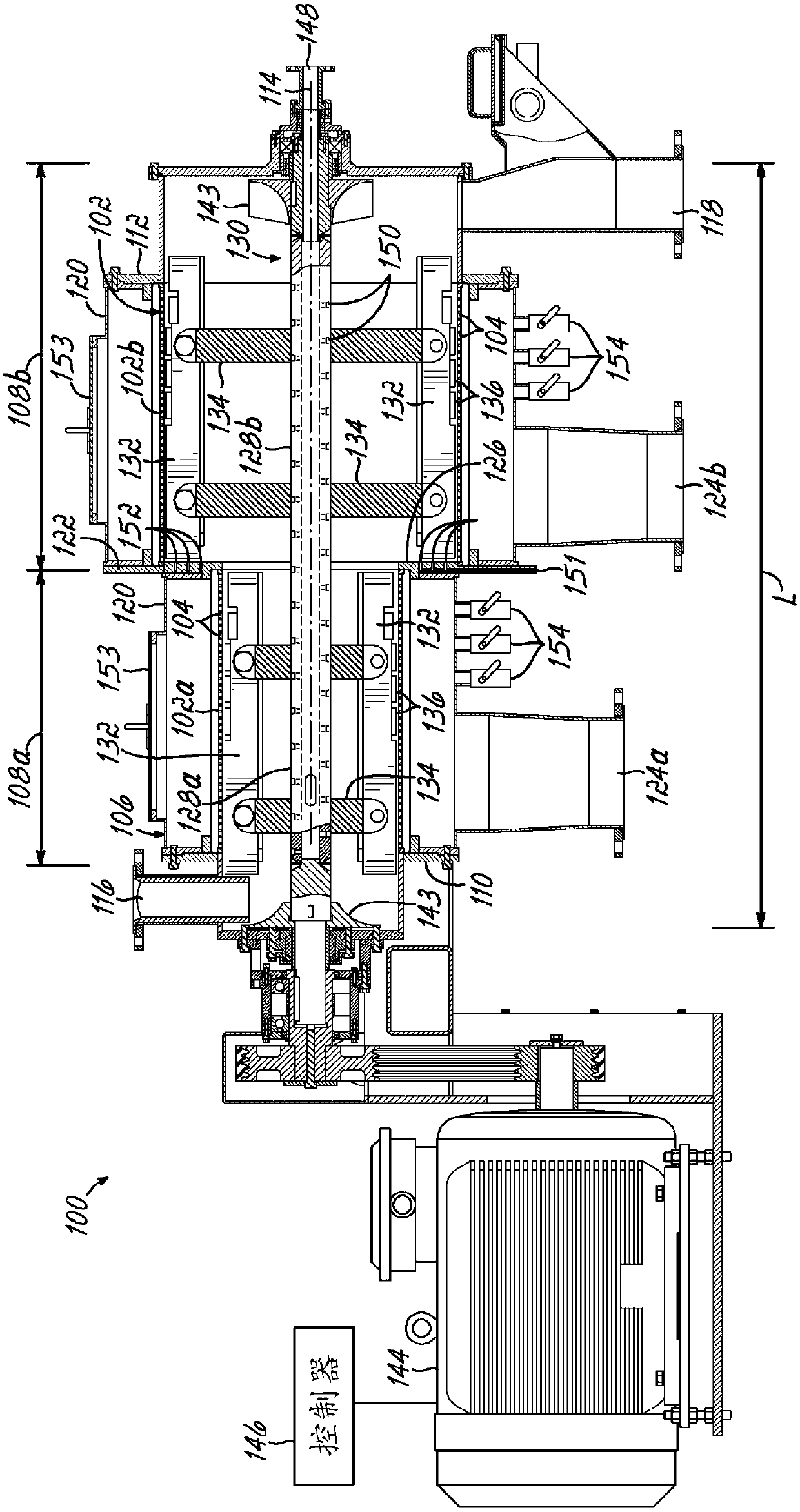

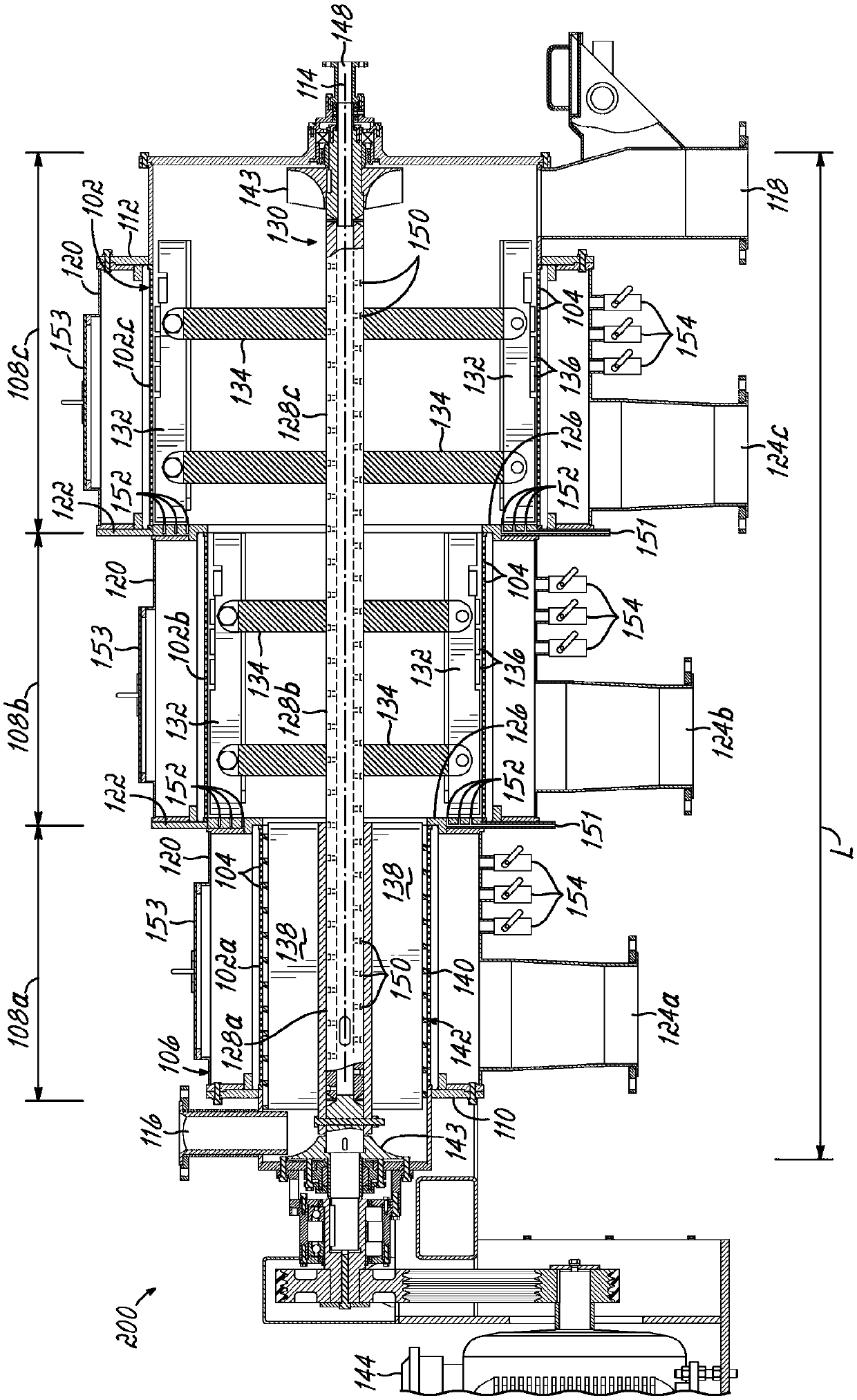

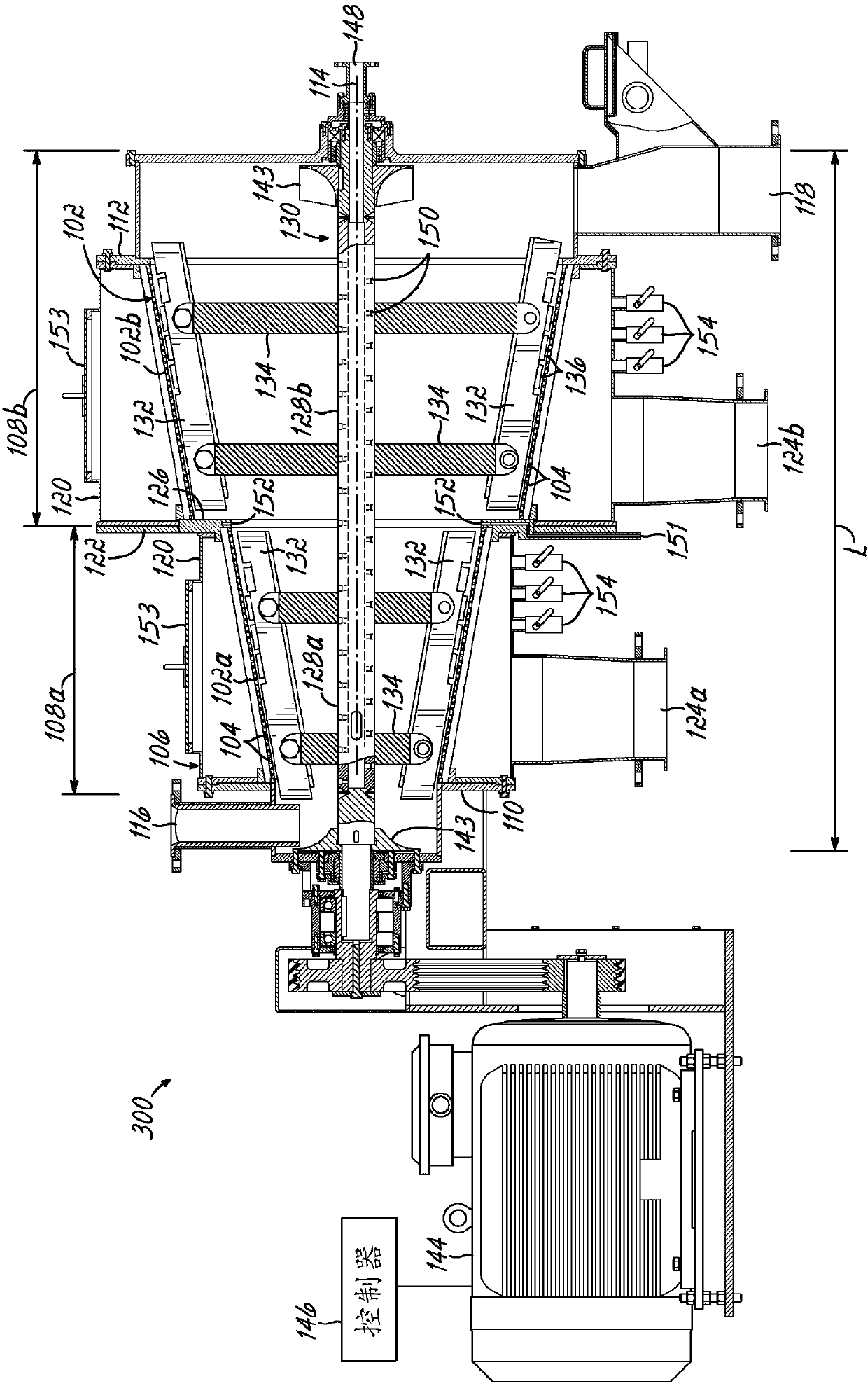

[0018] According to an embodiment of the present invention, figure 1 Apparatus 100 is shown for ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com