Novel aluminum alloy transmission shaft

A technology of aluminum alloy and drive shaft, which is applied in the field of drive shaft, can solve the problems of drive shaft damage, etc., and achieve the effect of solving the problem of string motion, eliminating string motion, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

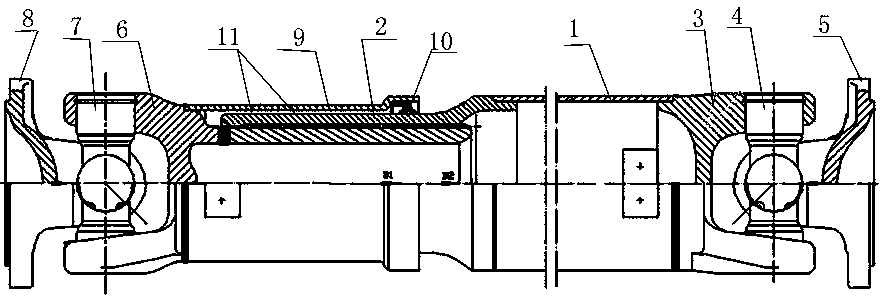

[0022] The present invention as figure 1 shown.

[0023] A new type of aluminum alloy transmission shaft, including an aluminum alloy shaft tube 1, one end of the aluminum alloy shaft tube 1 is provided with an aluminum alloy universal joint fork 2, and the other end is provided with an aluminum alloy spline sleeve 3, forming an integrated structure; The knuckle fork 2 is connected with the flange fork 2 through the cross shaft 2 4, and the aluminum alloy spline sleeve 3 cooperates with the spline shaft fork 6 and is connected with the flange fork 1 8 through the cross shaft 1 7;

[0024] The aluminum alloy spline sleeve 3 cooperates with the spline shaft fork 6 to form a spline pair, the spline shaft fork 6 is provided with a sheath 9, and the joint of the aluminum alloy spline sleeve 3 and the spline shaft fork 6 is covered by the sheath Inside 9, there is also a maintenance-free sheath oil seal 10 between the sheath 9 and the aluminum alloy spline sleeve 3, so that the spl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com