Fixtures for handling insulation bricks

A technology for fixing devices and thermal insulation bricks, which is used in transportation and packaging, containers to prevent mechanical damage, and external accessories. Collapse, guaranteed stability, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

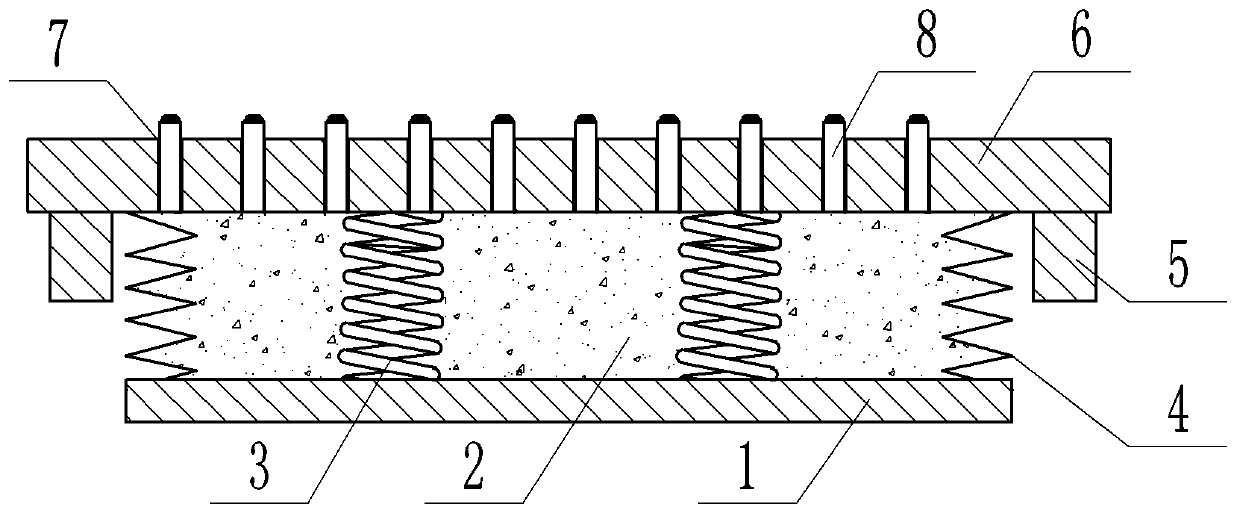

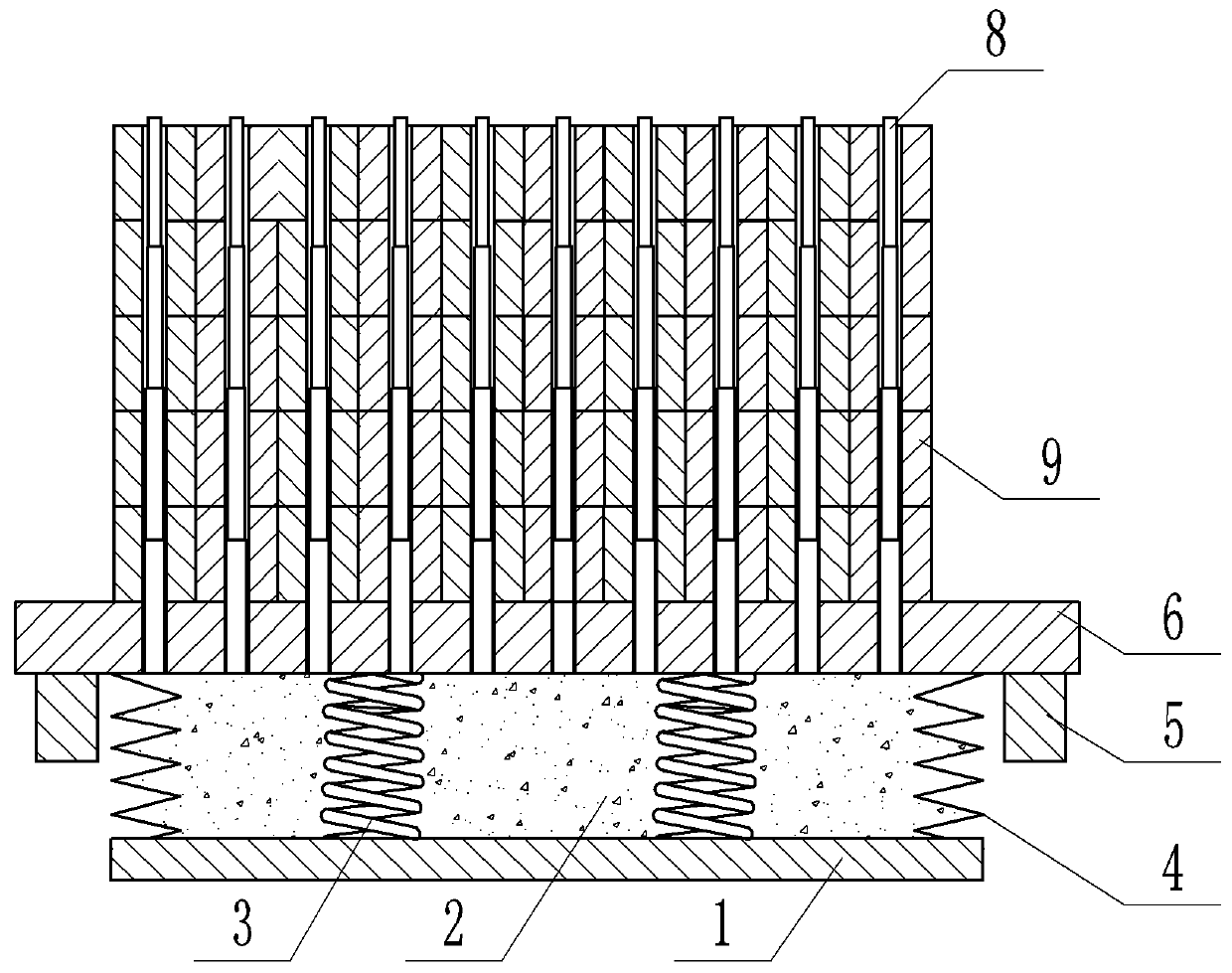

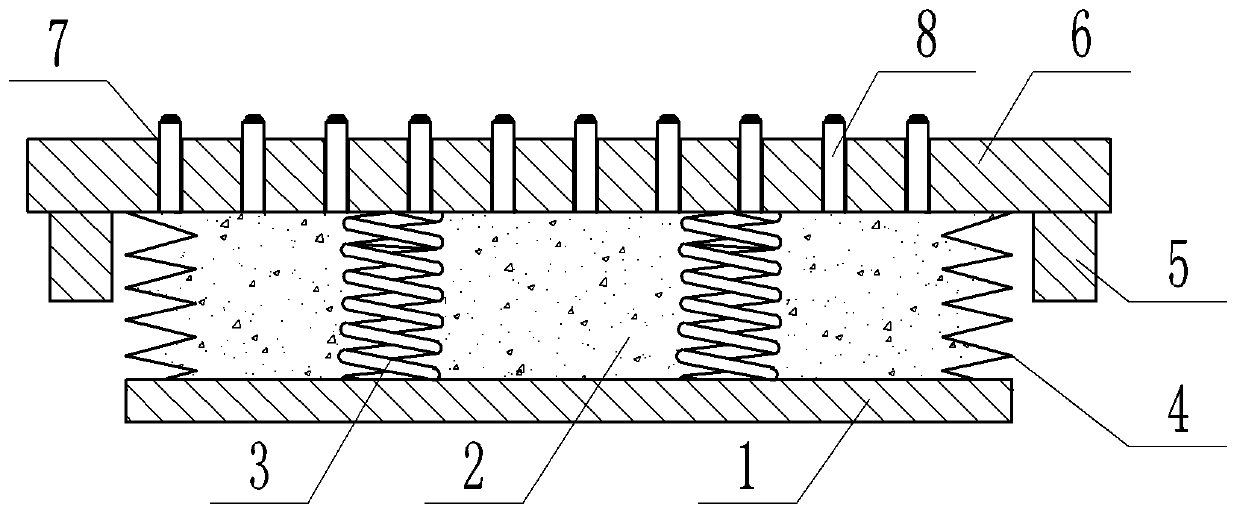

[0019] The reference signs in the drawings of the description include: base plate 1, hydraulic oil 2, spring 3, middle layer pad 4, lifting unit 5, support plate 6, communication hole 7, telescopic rod 8, and insulation brick 9.

[0020] Such as figure 1 , figure 2 As shown, the fixing device for transporting insulation bricks includes a bottom plate 1, a middle pad 4 and a support plate 6 from bottom to top, and the support plate 6 is a high-strength structural steel support plate 6. The middle pad 4 is fixed on the upper surface of the bottom plate 1 , and the support plate 6 is detachably connected to the upper surface of the middle pad 4 . The sidewall of the middle pad 4 is arranged in a folded shape, and applying force to the middle pad 4 can compress the middle pad 4 to reduce its height. The inside of middle layer pad 4 is full of hydraulic oil 2; Spring 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com