Method for drawing metallurgical performance evolution graphs of fuel in COREX gasification furnaces

A technology of gasifier and internal fuel, which is applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., to achieve the effect of optimizing utilization and solving comparison problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

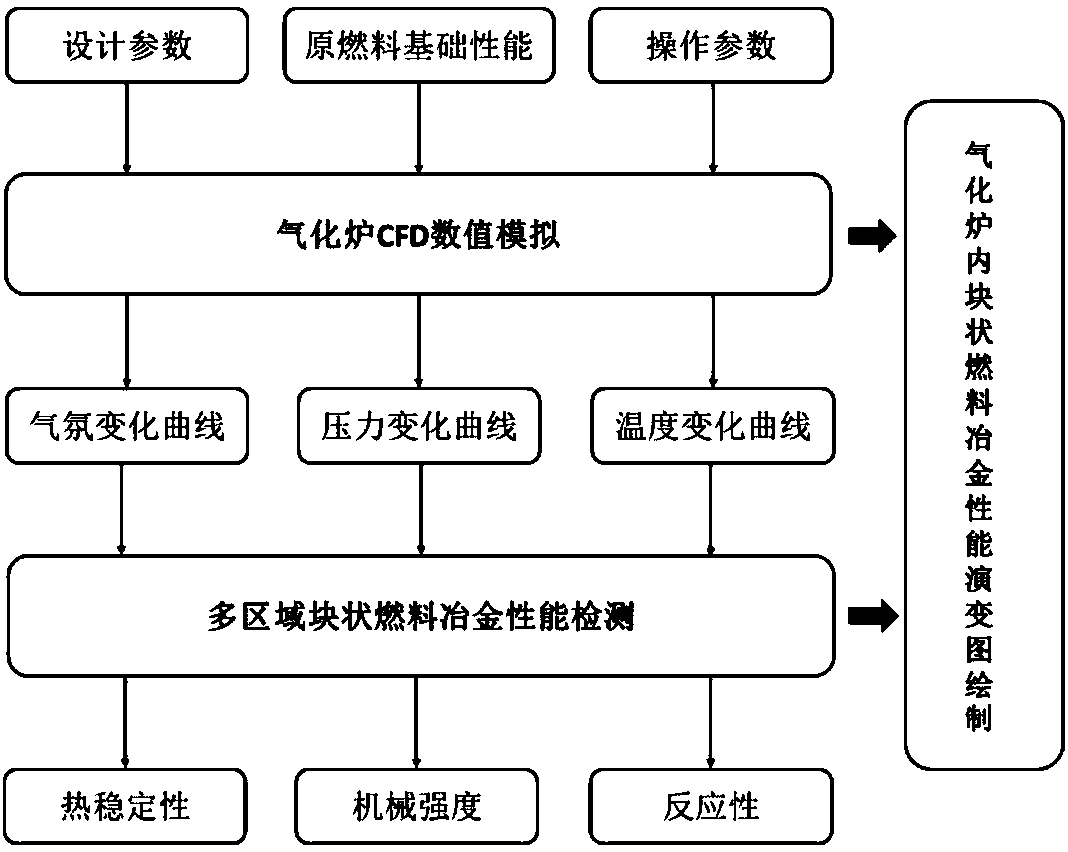

[0033] Drawing of metallurgical properties evolution map of bulk fuel in COREX gasifier

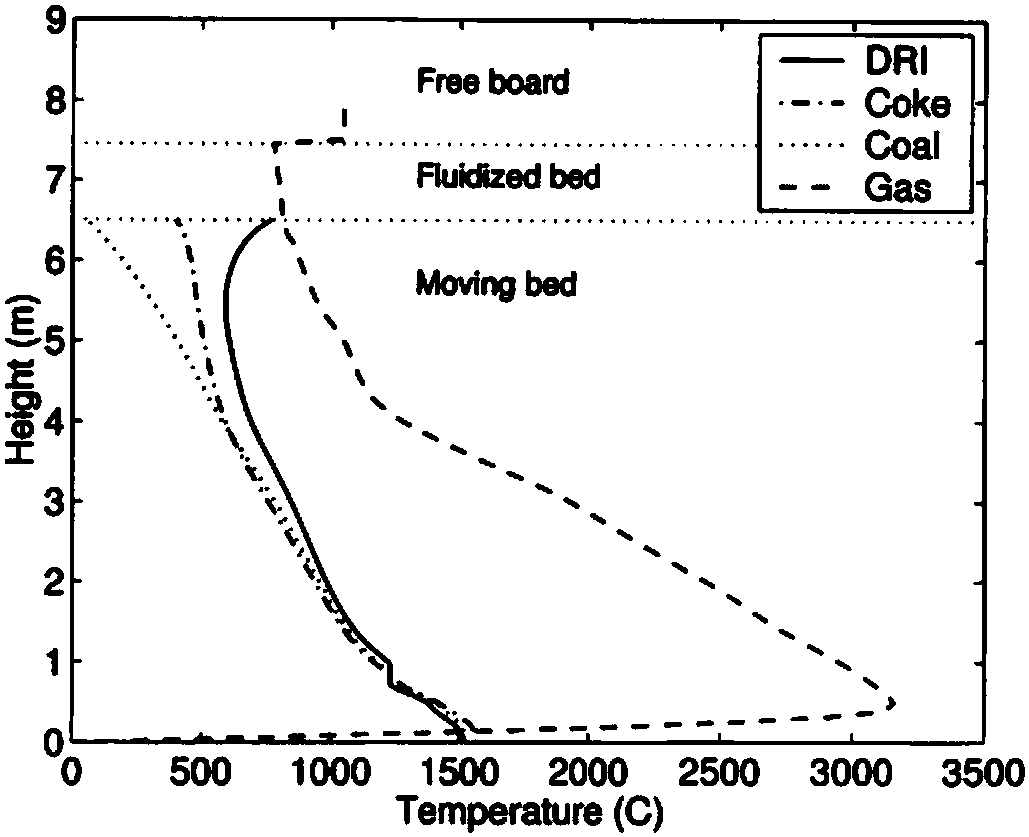

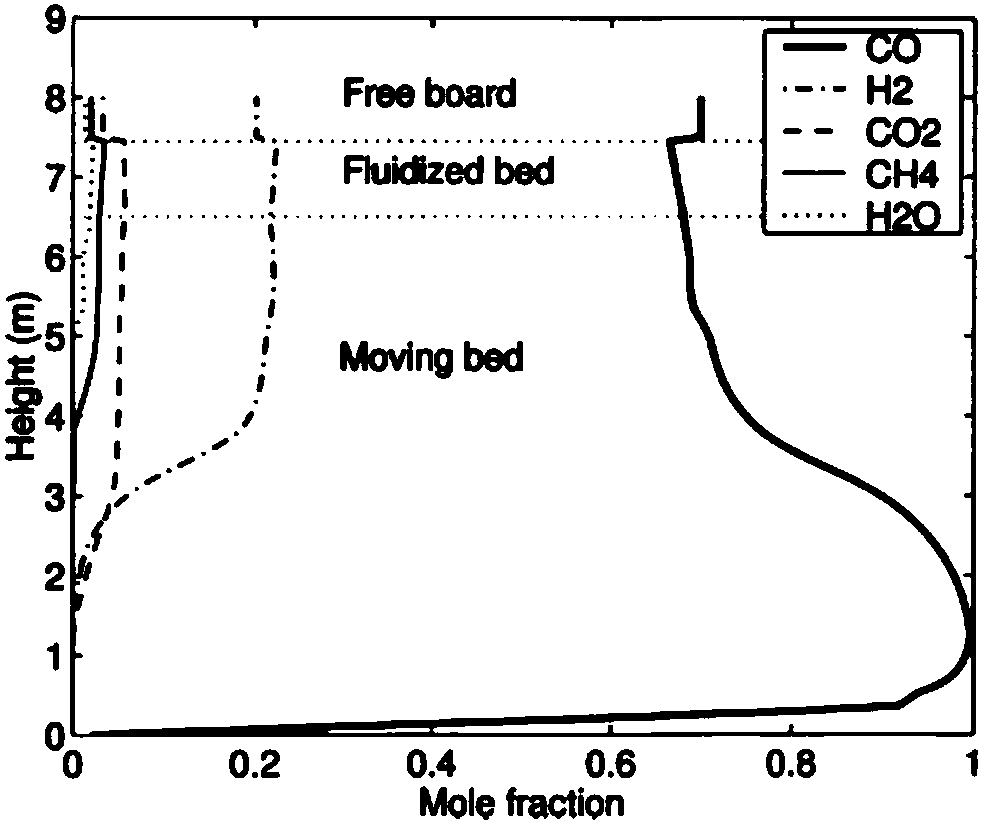

[0034]Step 1. Based on the design parameters of the COREX gasifier, the basic performance of the raw fuel and the operating parameters of the gasifier, CFD simulation software is used for modeling and numerical simulation to generate the change curve of the temperature of the fuel material column in the gasifier with the height of the fuel material column, Generate the change curve of the content of each component in the atmosphere in the gasifier with the height of the fuel material column, generate the pressure change curve of the cross-section of the fuel material column at different heights in the gasifier with the height of the fuel material column, and obtain the fuel material column Correspondence between the height value and the CFD simulated temperature value of the fuel column at the corresponding height, the CFD simulated content value of each component in the gasifier atmospher...

Embodiment

[0048] The technical route of this embodiment is as follows: figure 1 shown. First, determine the working environment of the block fuel, then perform multi-region block fuel performance testing, and finally draw the block fuel height displacement-performance evolution diagram.

[0049] Based on the design parameters of the COREX gasifier, the basic performance of the raw material and the operating parameters of the gasifier, CFD simulation software was used for modeling and numerical simulation, and the temperature change curve of the charge inside the gasifier and the distribution of the atmosphere in the gasifier were obtained as follows: figure 2 with image 3 shown.

[0050] A multifunctional high-temperature furnace was used to simulate the temperature, atmosphere, and pressure changes of the block fuel in the process of descending in the gasifier, and samples were taken to analyze the metallurgical performance results (thermal stability, mechanical strength, and react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com