Flame retardant finishing equipment

A flame retardant finishing and equipment technology, applied in the field of flame retardant finishing equipment, can solve the problems of rough equipment, stiff and simple cloth, etc., achieve good production effect, high production efficiency, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

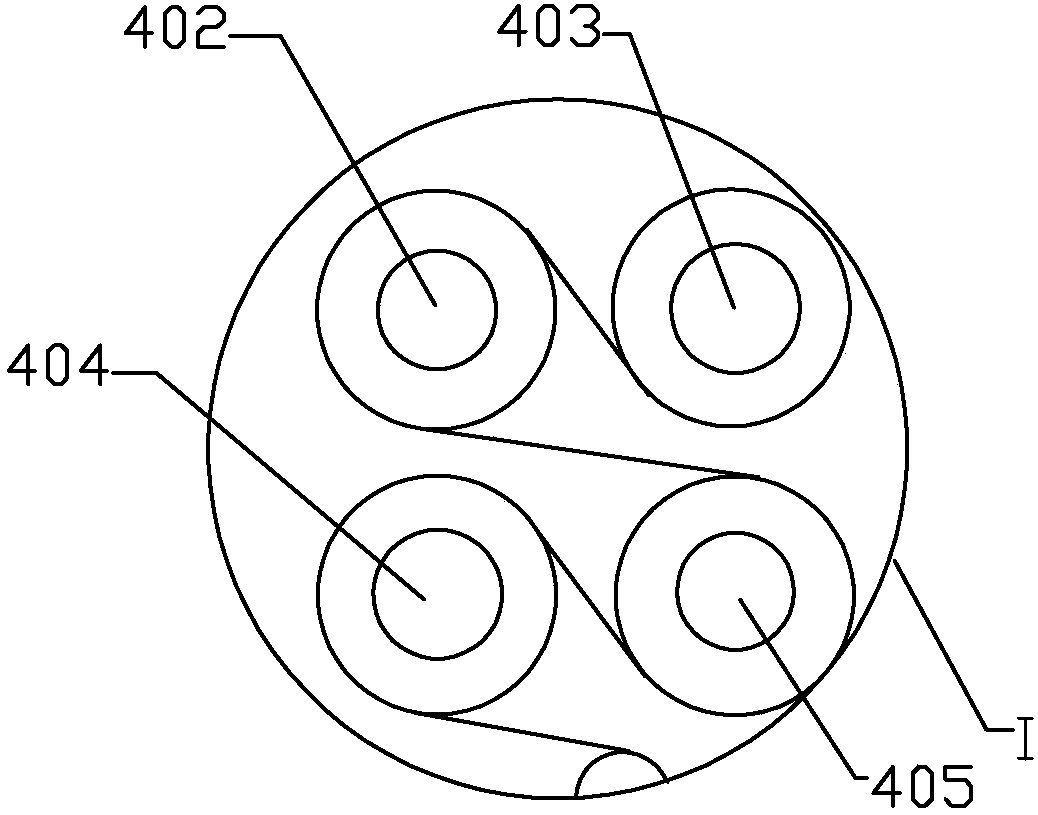

[0030] The difference between this embodiment and Embodiment 1 is that: the two upper guide rollers and the lower two guide rollers are respectively provided with a heating guide roller and a cooling guide roller. If the upper guide roller one 402 and the lower guide roller four 405 are heating guide rollers, then the cloth 2 passes through the upper guide roller one 402, the lower guide roller four 405, the upper guide roller two 403, and the lower guide roller three 404 successively; The first 402 and the third lower guide roller 404 are heating guide rollers, and the cloth 2 can be bypassed according to the first embodiment or the above-mentioned order.

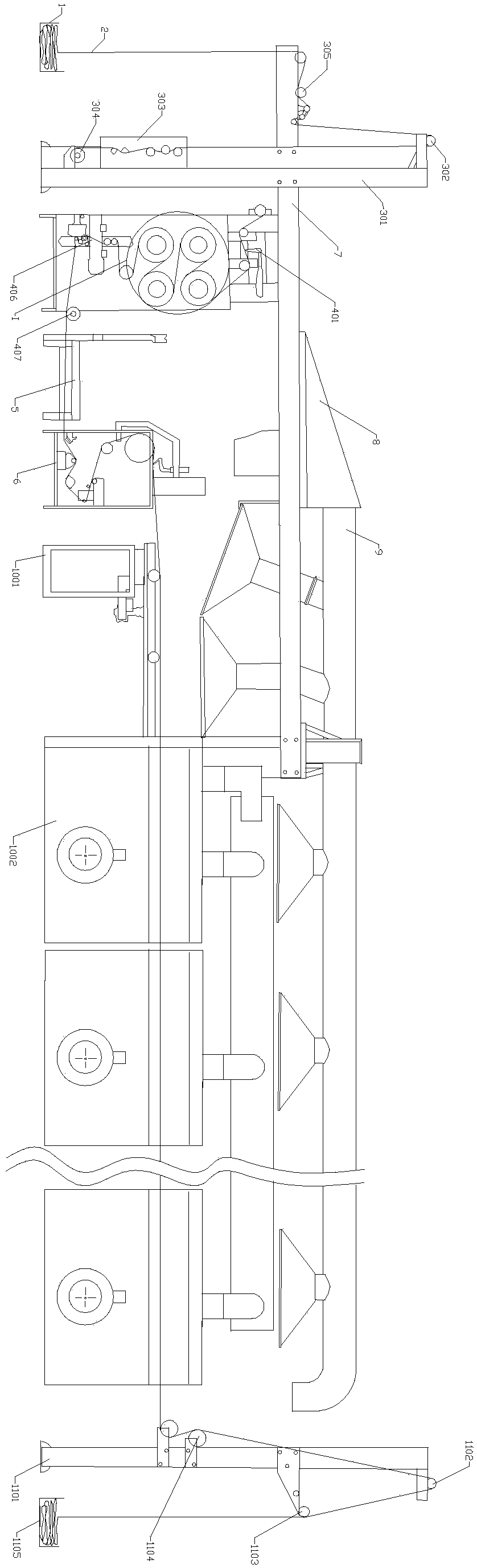

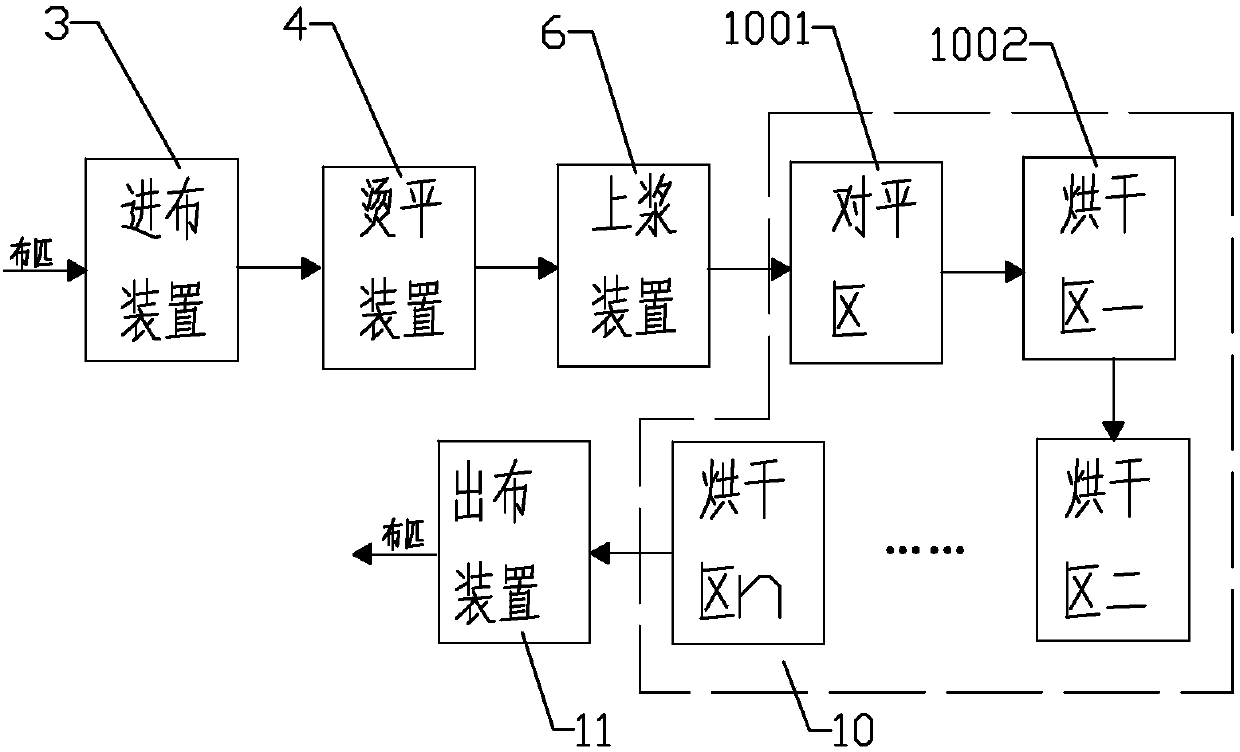

[0031]Based on the above, the present invention provides a flame retardant equipment for automatic finishing of the whole process, which can realize a complete set of processing flow from cloth 2 feeding, flame retardant finishing to cloth 2 output, and ensure the finishing of flame retardant finishing cloth 2 Quality and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap